Линия переработки отходов полиэтиленовой ткани пленки

- Категория: >>>

- Поставщик: Laizhou Xixin Machinery Co. Ltd.

Сохранить в закладки 62402020902:

Описание и отзывы

Характеристики

Product Application

Waste plastic pp pe film washing recycling machine

This washing recycling line adopt the Europe design with high quality. It used to recycling the waste PP/PE/HDPE/LDPE film,plastic bags, woven bags, sack and so on. We have many years experience in the plastic film recycling. We can customize make theline according to your requirpment.

We have special crusher,grinder machine for the film, sack, with special blades design and the mesh design;

so the output material is samller size but capacity is higher; It will help the washing the material more cleaning;

And save labor cost and save energy;

PP PE film washing recycling machine:

Belt conveyor →metal detector(Optional)→ Crusher (with water) → screw loader →Floating washer→screw loader →high speed friction machine →film dewatering machine→control cabinet

Model | Capacity (kg/hr) | Installed Power (KW) | Water Supply (m3/hr ) | Manpower (person) | Area Required (L*W*H) |

xj-300 | 300 | 120 | 4-5 | 2-3 | 23mx5mx3.5m |

xj-500 | 500 | 185 | 5-7 | 2-3 | 25mx6mx4.5m |

Xj-600 | 600 | 200 | 7-9 | 2-3 | 29mx6mx4.5m |

Xj-800 | 800 | 230 | 9-10 | 3-4 | 32mx6mx4.5m |

ME-1000 | 1000 | 270 | 10-12 | 4-5 | 40mx6mx5.5m |

A1: We have no MOQ and 1 set machine order is also welcomed .We usually quote FOB Qingdao price ,but if you want to know the other

Price Term, we will try our best to meet with your demands.

Q2: This is the first time I use this kind of machine, is it easy to operate?

A2: There is English manual that show you how to use machine. If you still have any question, please contact us by e-mail / skype/

phone /whatsapp/trademanager online service.

Q3: How to install?

A3: We adjusted machines well before we deliver. When customers receive them, you can work with them directly.

Q4:How to ensure the safety?

A4: There have the overload and over heat protection, it ensure working people safety.

Q5:How long the machine can be used?

A5: It depends how you use your table saw, if use it in good maintenance, at least 8-10 years.

Q6:what is the Delivery time?

A6: Our delivery time is around 30 days. Before the machine arrive at the port, the shipping company will call you.

Похожие товары

Высококачественные стеклянные косметические флаконы с распылителем для духов, 100 мл

Одиночный свет лишение теплицы оборудованный стеллаж для выращивания вертикальной гидропонной системы теплицы для саженцев клубники

Оптовая продажа, 5 футов, гибкий виниловый рулон с блестками цвета розового золота

Высококачественные Модные Цветные часы OEM минималистский цвет Sunray циферблат Роскошные наручные часы

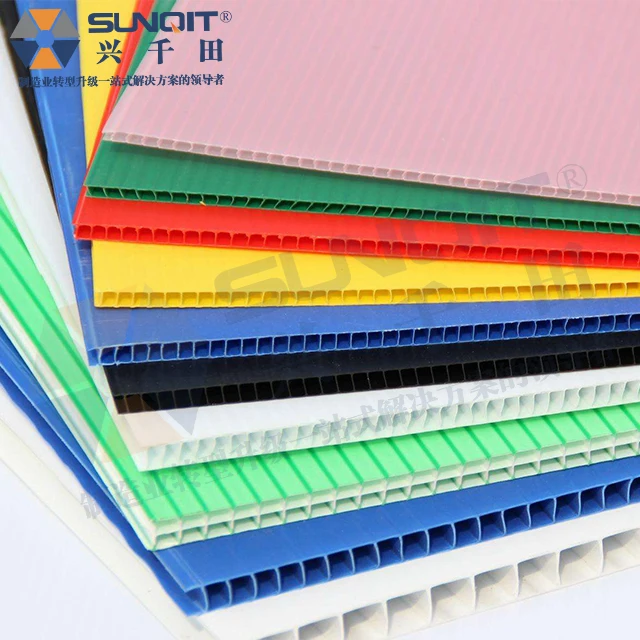

Высококачественные антистатические водонепроницаемые пустотелые листы по лучшей цене, нетоксичные легкие Полипропиленовые Гофрированные Пластиковые пустотелые листы

Оптовая продажа продукции, вращающаяся Конвекционная печь, кондитерское оборудование, инструменты для выпечки, большая печь для выпечки

Ручной работы подгонять одежду организовать коробки Высочайшее качество чувствовал коробка для хранения

Новые поступления

Новинки товаров от производителей по оптовым ценам