Инспекционная камера SIPOTEK проверка дефектов

- Категория: >>>

- Поставщик: Shenzhen Sipotek Info Technology Co. Ltd.

Сохранить в закладки 62416447717:

Описание и отзывы

Характеристики

Sipotek Customized Automated Optical Inspection Sorting Machine

1. Model type: T300

2. Machine characteristics: special vibration disc automatic feeding mechanism

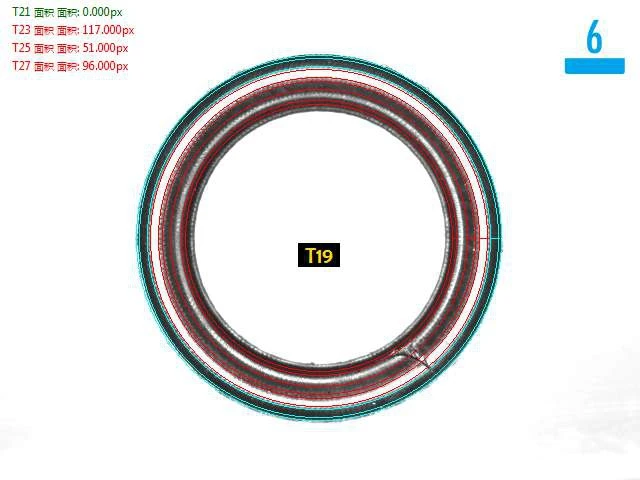

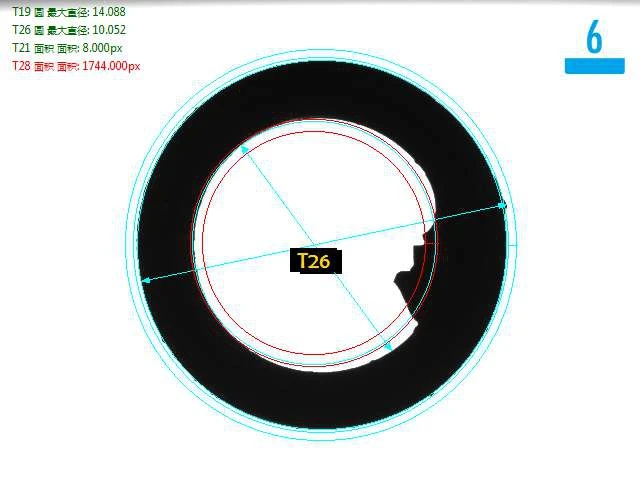

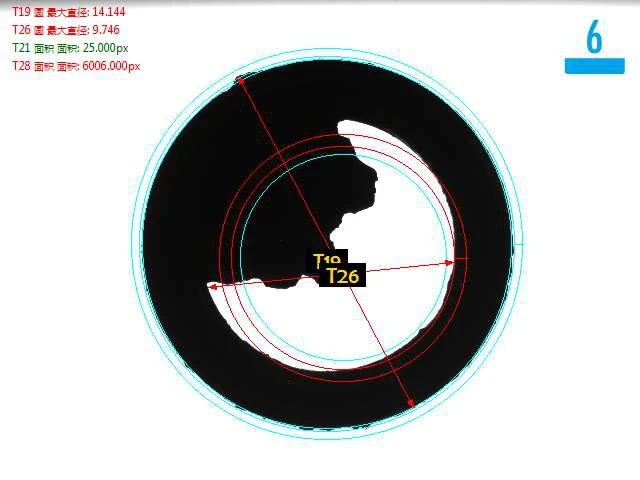

3. Main functions: inspection of length, height, diameter, mixing, deformation, missing material, burr, black spot, scratch, etc.

4. Trial scope: suitable for testing rubber ring, screw, mobile phone accessories, stainless steel, aluminum, plastic and other devices

5. Detection accuracy: the highest accuracy can be up to 1mu

6. Detection efficiency: The highest detection speed can reach 1200 branches per minute.

Design, production, installation and assistance of visual inspection systems since 2002.

Standard, Non-standard customized, inline/online, offline, dimensional measurement, appearance defective inspection.

Machine Specification Example Sipotek designs and produces what is suitable for your products with effectiveness. | ||||

1 | Machine Type | High speed Inspection Machine (Glass plate) | ||

2 | Industries Serve | For parts can lie stable such as screws, nuts, lathe parts, stamping parts, injecting model, cooling elements and fasteners. | ||

3 | Turntable | Dedicated round glass turntable | ||

4 | Optical System | Germany high magnification CCD industrial camera, Japanese lens, professional light source system | ||

5 | Camera Quantity | Standard with 3 ( 1-8 optional) | ||

6 | Operate System | Germany Siemens Industrial Computer | ||

7 | Video Inspection Software | Sipotek Machine Vision Inspection System | ||

8 | Feeding System | Dedicated feeding guide line, vibration feeder x 1 SET, automatic feeding and container devices (optional) | ||

9 | Package System | Automatic counter and package machine (optional) | ||

10 | Inspection Speed | 300-1200 pcs/min | ||

11 | Accuracy | Highest level up to±0.01mm | ||

12 | Inspection Details | Appearance inspection: outer side, inner side, opposite, Diagonal, length, height, concentric, roundness, step size of each part, angle, sharpness and etc | ||

Defective inspection: 360 degrees teeth, rotten tooth, bad tooth, oblique tooth, threading, inside burr, missing material,Internal hole blockage, cracking, glitch, solder joint area,Imprint, with or without internal teeth, inspect all functions of screw with flat head | ||||

13 | Power and Voltage | Two phase 220v, 50Hz | ||

14 | Rated Power | 1KW | ||

15 | Air Pressure | Not lower than 0.35-0.7MPa | ||

16 | Weight | Around 500kg | ||

17 | Working Temperature | -3℃~45℃ | ||

18 | Storage Temperature | -20℃~60℃ | ||

19 | Machine Dimension | 1000mm (Length) X 1000mm (Width) X 1800mm (Height) | ||

Please check below our mainly machine components

Machine Parts

Name: Vibration Bowl Feeder

This is an important input mechanism, mostly designed like a bowl. For offline inspection, you will feed the products into the bowl, then they will run and run until being able to stand still one by one with sequence. In this way, they will be ready for inspection.

Machine Parts

Name: Industrial Cameras

Our machine inspection system uses optical image processing system. The cameras are playing an core role since we are visual inspecting by clear and visible images. Which are captured by industrial cameras, with HD, FA optical lenses, and under sufficient light sources. Our cameras are mostly SONY and BASLER.

Machine Parts

Name: Glass Rotary Plate

It's a high speed turntable where all the target are image-captured and quality-inspected. Looking like a platform, it was designed with professional thickness and shape. The targets will be carried on this plate with a high speed setting by the system.

Machine Parts

Name: Operation Section

This is the place where the operator manipulate the machine. There will be an LCD screen display what's inspecting on the way. You can check the defects, the quantity, and on/off the machine, etc.

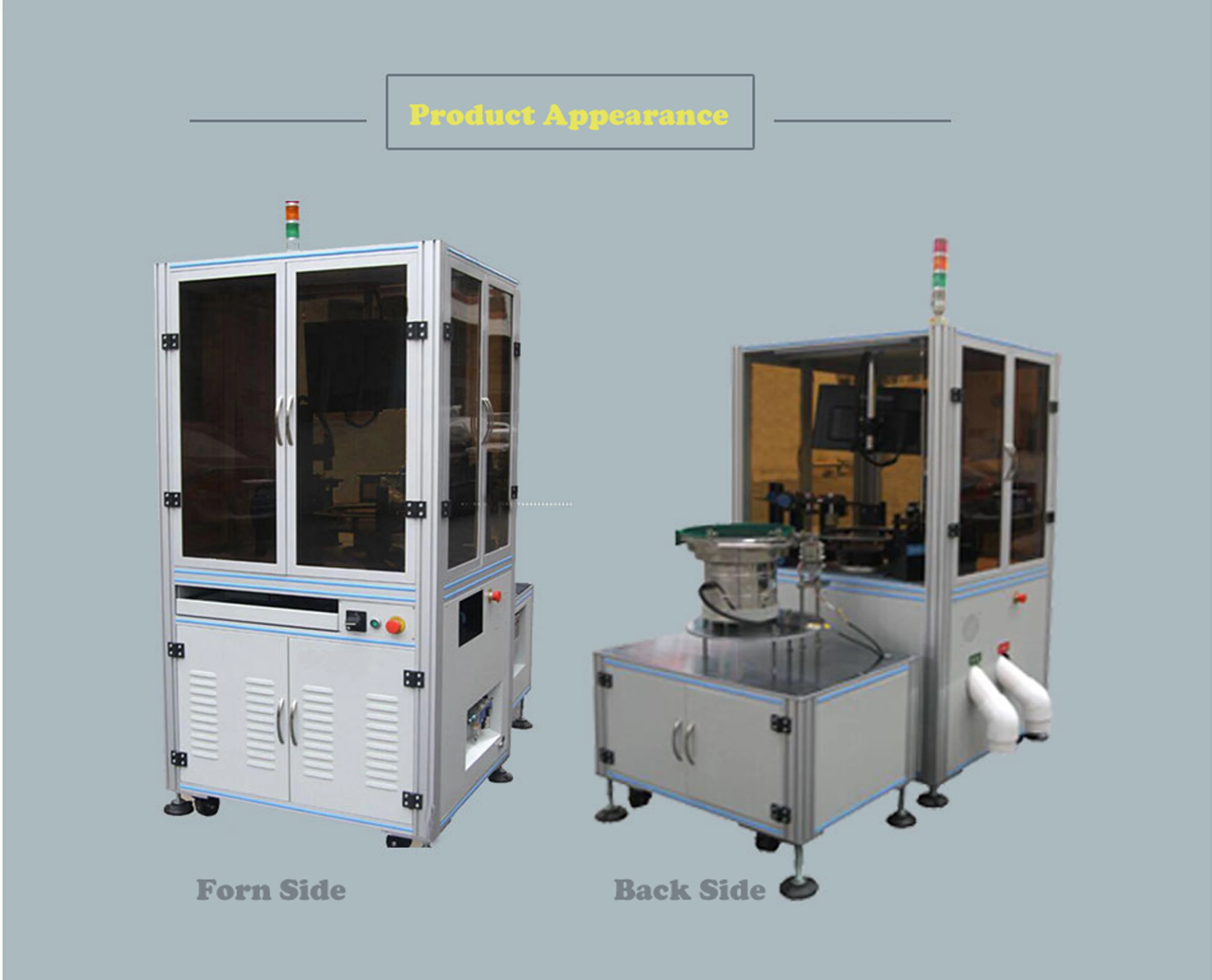

The machine is composed by different components, but mostly 3 main parts. the input, inspection section and output. The body is compact and space-saving, the installation is easy.

They explains where the inspection starts, how the objects are inspected and where are they loaded.

If you are confused of which is the part and what they are used for, please contact us at any time.

We can be reached by what's app, wechat, skype, emails and phone.

Sipotek provides professional sample testing service and solution designation before order.

Our business procedures are sincerely communicating with customers, understanding fully what they need.

Step 1 Inquiry and communication

We will discuss as many details as possible to understand best of your inspection requirements. So we are available not only by phone or emails, but also on line chatting with Skype, Wechat, What's app and Alibaba. The contents of the communication will include inspection details, drawings, accuracy, speed, input and output, etc.

Step 2 Samples arrangement

Since our machine is customized designed according to customer's demand. Samples are necessary. Our engineers can make the solution depending largely on the lighting test of the samples. Thus we can check which is the defects, where can we find them under specific lighting source.

Step 3 Inspection solution Finished

After our engineer finished the sample testing procedure. They will give a result of the test and then will be reported to you. You can find what will be composed in the machine and how the result shows the sample images.

Step 4 Customer make decision

Now our customers will have the solution report, They will make a determination of the inspection project. PI will be sent and Order will be confirmed after their acceptance.

Step 5 Put into production

After orders are confirmed, we will discuss the producing technology and then start to make the customized machine. At the same time we will confirm the delivery date.

Step 6 Machine Delivery

Generally, our trade term is FOB Shenzhen. We strongly recommend our customers to verify the machine in our factory before shipment in case any problems or changes will be and we could solve them before shipped to destination. Meanwhile, customers can have a free training for the machine operation and installation.

Packaging | ||

Size | 900 (L) * 800 (W) * 1850 (D) [mm] | |

Weight | 300-500KG | |

Packaging Details | The normal package is wooden box. If export to European countries,the wooden box will be fumigated.If container is too tighter,we will use pure film for packing or pack it according to customers special request. | |

Shenzhen Sipotek Technology Co., Ltd.

Since we established 16 years ago, we has been committed to the research, development and manufacturing of image technology and machine vision, with more than 70 senior R&D personnel of machine vision system and industrial automation engineers.

Anhui Sipotek Technology Co., Ltd.

We have professional specialists in high performance machine vision and vision systems field.

Our team provides Immensely powerful, state-of-the-art automated quality control machine vision inspection systems and machines.

It's a new generation of class-leading vision system, better in every way. Faster, more efficient and integrated by our experts.

It's Easy to use. Our vision systems are also practical and simple to maintain.

Machine Vision Inspection Application and Solution

The company's key technical personnel are mainly from huawei, byd, foxconn and other first-class manufacturing enterprises, with many years of mature experience in software design, visual and image comparison technology, industrial automation and other aspects

Sipotek Attended Fairs for Automation Inspection Field

Our machine is designed according to customer's requirement. Sipotek is a professional machine vision inspection robot supplier and manufacturer. Besides, it's our honor to produce SONY industrial cameras with trustworthy techniques. We welcome our customer to visit our website and discuss with us online. If you want to visit our company and see how the inspection machine working, please visit our company and let us know in advance so that we can make a good preparation for you.

.

Welcome to visit our company!

Before we can design a suitable inspection system for your products, we need to confirm as many details as possible. We will collect all the requirements which will be supportive for our R&D team to do the test and design a solution.

Sipotek is a professional machine vision inspection supplier and manufacturer. Welcome to visit our website and discuss with us online. If you want to make a schedule to visit our company, please let us know in advance so that we can make a good preparation for you. We welcome our customer to plan a visit to our company and watch the machine demo. If you are interested in automated inspection system or machine vision solution, please contact us for more information.

For Product Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: +86-18617182707

Website: https://www.sipotek.net

Похожие товары

Простая в эксплуатации полностью автоматическая машина для проверки света

Products inspection company in China Stoneware Mug Inspection Service

Услуги по проверке продукции Amazon

Контроль качества пива Бонг/контроль качества пива Бонг/компания по контролю качества пива Бонг

Инспекционная служба световой трубки jiaxing/Служба контроля качества dongguan/manuli service на месте в Шэньчжэне

Electric product quality control service led lights inspection service in China

99.99% hand sanitizer inspection service in China

Новые поступления

Новинки товаров от производителей по оптовым ценам