| ||

Машина для выбора и размещения GP600/автоматический погрузчик печатных плат/Производственная линия SMT

- Категория: >>>

- Поставщик: Beijing Glichn S&T Development Co. Ltd.

Сохранить в закладки 62421828208:

Описание и отзывы

Характеристики

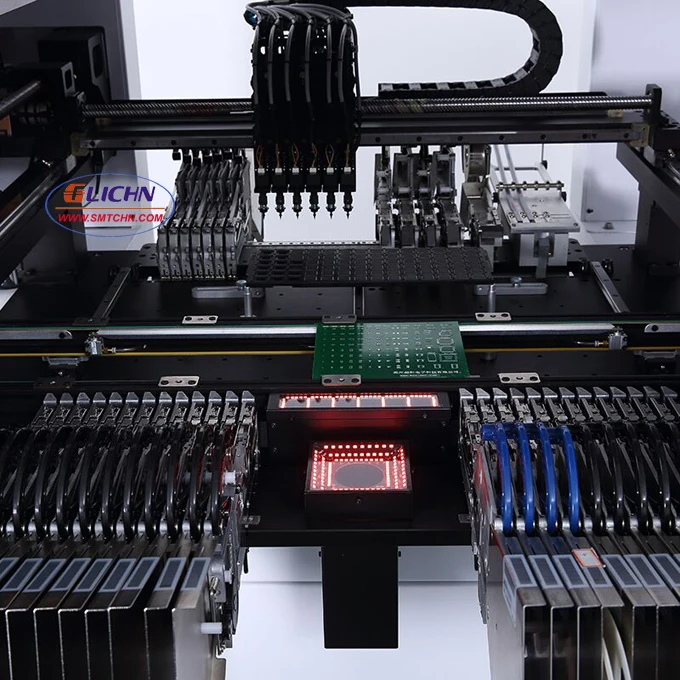

Pick and place machine GP600

Pick and place machine GP600 Number of feeders | 64 |

Number of head | 6 |

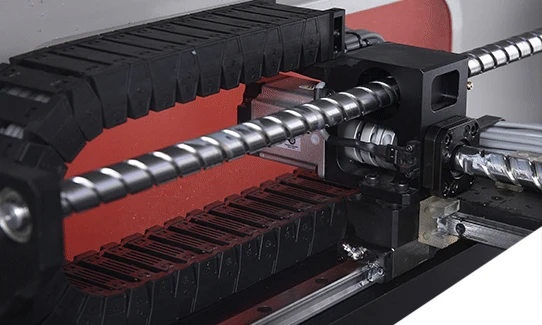

XYZ Drive Guide Rail | TBI High-precision heavy-duty straight-line guide rail |

Number of camera | 8 |

Maximum circuit board area | 510×450mm |

Number of IC Tray | 48 |

Average power | 500W |

Positioning precision | 0.01mm |

The buffer range of suction nozzle | 4.5mm |

Power supply | 220V, 50/60Hz |

Compressed air | 0.5-0.6Mpa |

Drive motor | Panasonic servo motor |

Vacuum source of suction nozzle | high-speed on-off vacuum generator with vacuum breaker |

Maximum travel scope in Z axis | 20mm |

Tape feeder | 8, 12, 16, 24mm and vibration suction (mounting pipe chip) |

Maximum mounting speed | 11000 Pcs/h |

Average mounting speed of actual mounting resistance | 9200Pcs/h |

XYZ drive guide rail | TBI high-precision reloading linear guide rail |

Motion drive system | Panasonic high-speed DSP drive |

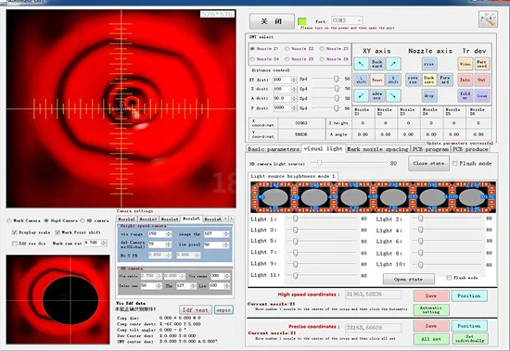

Operating system | full-automatic chip mounter operating system independently |

developed by Huawei Guochuang based on Windows | |

operating systemand it supports windows xp | |

win7 operating system | |

Element angle | 0-360°, synchronous rotation during movement |

X/Y operation mode | intelligent curve of the linear acceleration and deceleration linkage |

MARK point positioning | full-automatic (the MARK point can be adjust at will) |

Intelligent alarm | automatic correction, automatic filling, feeding shortage alarm |

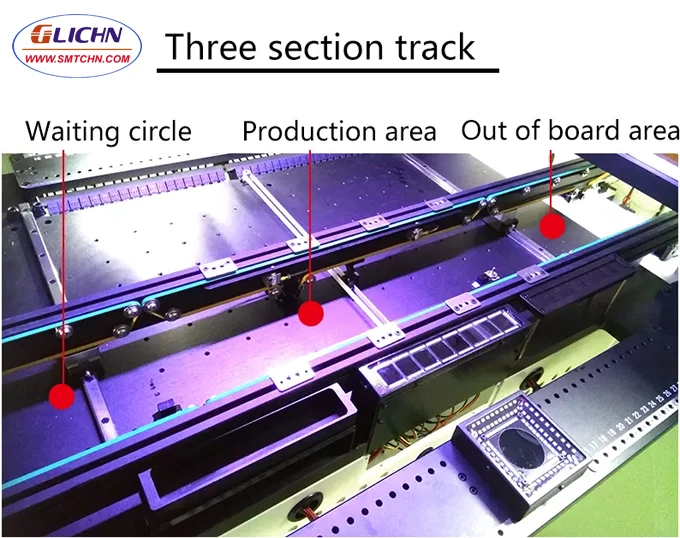

Plate entering mode | automatic connection from left to right in single sections, |

automatic PCB transfer positioning. /plunger positioning, | |

manual plate feeding. | |

Visual display | 17-inch industrial control display, 4:3, resolution: 1280 x1024 |

Number of recognition cameras | One Mark recognition camera, four quick-recognition cameras |

and one precise-recognition camera | |

Number of recognition cameras | One Mark recognition camera, six quick-recognition cameras |

and one precise-recognition camera | |

Adaptive mounting scope | Adaptive to 0201, 0402, 0603, 0805, 1206, diode, audion, SOT, QFP |

within 40*40mm and the pin distance ≥0.3mm | |

(0.5mm center distance) and BGA | |

Product weight | 680KG |

Dimension | 1316*1360*1340mm |

GLICHN found in 2010,Specializing in SMT equipment manufacturing services and sales of peripheral products. Factory is located in shunyi district of Beijing and shenzhen baoan district

SMT class:pick and place machine,small and middle size reflow oven, manual and semi-automatic solder paste printer,PCB loader and unloader,PCB magazine rack,SMD component counter,solder paste and chip production line etc.

THT Class:wave soldering machine, Spray tin stove,cut foot and forming machine,Plug-in production line etc

Others :Spin coater,Dispensing machine,nozzles,feeder,belt ,driver, motor,cylinder,High temperature tape,valve,etc

1. We’ll have a good check and a test before shipping out.

2. We provide you the friendly English User manual or the operating videos for free;

3. 24 hours technical support by email or Skype or Trade Manager or Calling.

4. 1 year machine parts free warranty;

5.Engineers available to service machinery overseas.

1 set machine, mixed order is also welcome.

a. How can I buy this machine from you? ( Very easy and flexible !)

b.Consult us about this product on line or by e-mail.

c. Negotiate and confirm the final price , shipping , payment methods and other

terms for machine.

d.Send you the proforma invoice and confirm your machine order.

e. Make the payment according to the method put on proforma invoice.

f. We prepare for your machine order in terms of the proforma invoice after confirming your full payment. And 100% quality check before shipping.

g.Send your machine order by air or by sea.

Why choose us ?

a. Best price & Best shipping & Best service

b. Ten years of experience in research and development production and sales

c. Six years of alibaba gold supplier

d. Trade assurance

Похожие товары

KAYO-50P pcb автоматический погрузчик

Высокое качество SMT PCB погрузчик разгрузчик HY-250ULD автоматический PCB погрузчик разгрузчик

Smt Pick And Place Machine Smt автоматический Pcb конвейер Pcb погрузчик/разгрузчик

Двухстороннее направление, V-образный канал, машина для резки печатных плат, вся панель PCBA Depanelizer

Лучшая цена, высокое качество, Пользовательский логотип на месте, автоматический SMT мини PCB box погрузчик, Штабелируемый завод из Китая

Фермерская буксируемая Солнечная Центровая система орошения на продажу

Ysw стоит купить нагреватель циркулирующего двигателя термостойкий материал термостатический нагреватель плавкого предохранителя

Новые поступления

Новинки товаров от производителей по оптовым ценам