FG 160 производитель Китай оборудование для сушки в псевдоожиженном слое фармацевтический

- Категория: >>>

- Поставщик: Wenzhou Liangke Machinery Co. Ltd.

Сохранить в закладки 62427847853:

Описание и отзывы

Характеристики

FG-160 China Manufacturer Fluid Bed drying Equipment Pharmaceutical

Technical Parameter

Item Parameter | FL-160 Fluid Bed Dryer | ||

Material tank | Volume | L | 520 |

Diameter | MM | 1285 | |

Production capacity | Kg/time | 120-160 | |

Power supply | Three-phase | 380V/50HZ | |

Steam | pressure | MPa | 0.4-0.6 |

Consumption | Kg/h | 100 | |

Compressed air | Pressure | MPa | 0.4-0.7 |

Consumption | Kg/h | 1.2 | |

Draught fan | Power | Kw | 15 |

Material temperature | ℃ | Auto-control and auto-display | |

Application range |

| Mainly used for producing and drying the instant granules, tablets and capsules in both Chinese and western medicines. | |

Obtaining ratio | % | ≥99% | |

Product moisture | % | Can reach 5‰-5% after drying | |

Noise | db | With isolating treatment, the noise of draught fan is less than 75 dB. | |

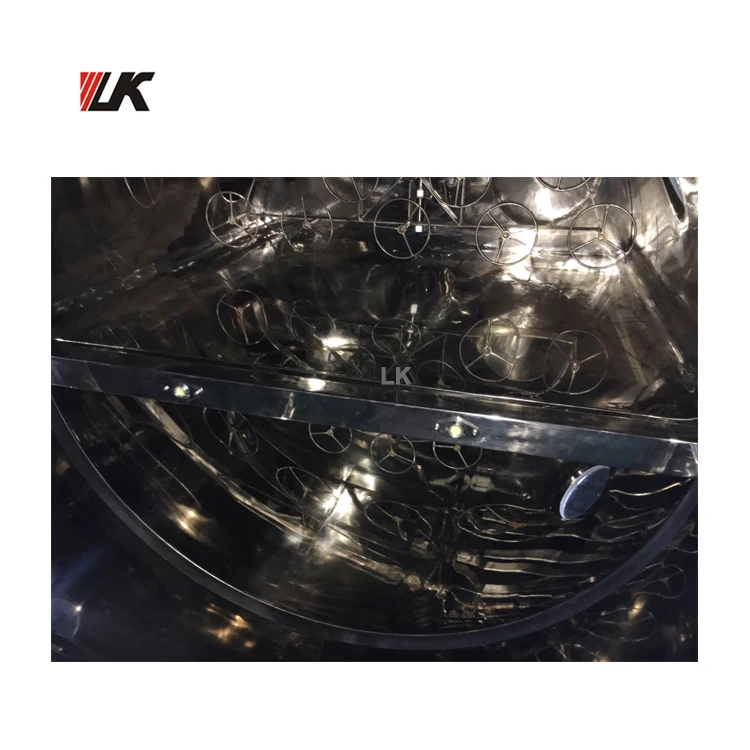

Material | All stainless steel and surface SUS304 with matte treatment, mirror-polish until Ra0.3-0.5 inside. | ||

Sealing type | Head pressure type with pneumatic cylinder, good sealing effect. | ||

Filtration of inlet air | It’s equipped with primary, medium and sub-high efficiency filters, so the air filtration level reaches 100000 (3μm). | ||

Air capacity regulation | Frequency control to regulate the air capacity. | ||

Steam heater | Use steam to heat, the material of heater is SUS304 | ||

Control method | PLC control, frequency converter regulating the air capacity, touch screen operating system, Chinese operation interface. | ||

Steam angle seat valve | Famous brand with high temperature control precision. | ||

GMP standard | Designed and manufactured according to GMP standard, in accordance with GMP requirements. | ||

Product standard | According to JB/T13755-92 standard | ||

Machine dimension | Refer to the installation drawing | ||

Application

Fluid-bed processing is mainly used for the mixing of powder material, drying and granulating (coating) in pharmaceutical, food, chemical, agricultural and sideline product processing industries, such as tablet, instant powder and condiment granules. The process of feeding and discharging material for this equipment should be finished in the airtight space to avoid the powder spreading to the working environment. It‘s controlled by PLC. For wet type granulating machine, it adopts negative pressure or air blast to make the finished granules enter the fluid bed for drying in airtight way.

Working Principle

Under the suction of induced draught fan, the heated and purified air will form into high-speed hot air flow to turn the materials in material chamber into fluid state under the function of stirring and negative pressure. The water will be evaporated quickly and discharged to dry the material.

Characteristics

Round structure inner fluid bed to avoid dead angle

The hopper can be set with stirring function to avoid wet material caking, especially for powder material, which is easy to clump together because of electrostatic adsorption.

It adopts manual rotation to discharge the finished products, convenient, fast and complete; it also can be designed with automatic inlet and outlet system as required.

This machine can be connected with high-efficiency wet mixing granulator and swing straightening granulator to suck the wet materials (powder and granules) into chamber for drying under the function of negative pressure, avoiding multiply transfers of materials.

Wenzhou Liangke Machinery has specialized in production of solid preparation process machine for more than 20 years, including wet granulator, roll compactor, fluid bed dryer, mixer, tablet press, coating machine, capsule filling machine etc. Also engaged in pharmaceutical trade,chemical trade as well as food trade with qualified team and mature technology.

Pre-Sales Service After-Sales Service

* Inquiry and consulting support. * Training how to instal the machine, training how to

* Sample testing support. use the machine.

* View our Factory. * Engineers available to service machinery overseas.

Похожие товары

Бытовая чистящее оборудование Запчасти для чистки чайных пятен

Прямая продажа с завода, гранулятор из нержавеющей стали с флуизированной платформой, таблетки для лекарств, гранулирование жидкостной платформы

Держатель для кухонных бумажных полотенец производственное оборудование рулон бумаги машинной намотки virgin планшет папиросной бумаги делая машину цена

Гидравлическая кубическая машина для производства угля для кальяна/оборудование для производства угля

BST600AF Z1/Z2 most used in korea compressor pump super silent high pressure Oil-free vacuum pumpAC220V110V380V440V105V120V240V1

Высококачественный гомогенизирующий смеситель для жидкого мыла в таблетках, лосьона, жидкого нагрева, оборудование

Биореактор рисунок планшет, Perfusion биореактор производства весы, трансгенные растения как Биореакторы ppt слайды

Новые поступления

Новинки товаров от производителей по оптовым ценам