Порошковый экстракт родиолы розовой

- Категория: >>>

- Поставщик: IE Polezhaev A.A.

Сохранить в закладки 62443440203:

Описание и отзывы

Характеристики

What is Description for Skin Whitening Rhodiola Rosea Powder Extract Powder?

Rhodiola Extract is the root of an arctic plant that is first and foremost an adaptogen - a substance that increases resistance to physical and mental stress. Rhodiola Rosea extract salidroside powder has a normalizing effect. However, Rhodiola does much more than that. Rhodiola Rosea extract also enhances your mood, focus and physical energy while reducing anxiety.

What is Function for Skin Whitening Rhodiola Rosea Powder Extract Powder?

1. Salidroside will improve immune function, relieve or dispel depressive symptoms;

2. Salidroside used to improve your constitution, Improve the hematopoietic function;

3. Salidroside has the effect of resisting lack of oxygen, anti-aging, anti-fatigue, and lower blood sugur;

4. Protecting cardiovascular, dilating coronary artery, preventing coronary arteriosclerosis and arrhythmia;

5.Skin Whitening,and anti-radiation.

What is Application for Skin Whitening Rhodiola Rosea Powder Extract Powder?

1.Applied in food field, it is widely used as functional food additive.

2.Applied in health product field, it is widely used to enhance immunity and resist melancholy.

3.Applied in cosmetics field, it is widely used to delay aging and compact skin.

4.Applied in pharmaceutical field, it is widely used to treat cardio-cerebrovascular disease.

Vacuum extraction

Thanks to this technology, for the subsequent dissolution of extracts, you can use liquids such as water, tea, coffee, juices, with the complete preservation of the complex of biologically active substances of plants (BAS).

The most important task of processing medicinal plant materials is to preserve the entire complex of biologically active substances of plants. Natural plant biologically active substances are the best alternative to synthetic substances since they are evolutionarily closer to the human body, practically do not cause side effects and are easily involved in metabolic processes.

Not all active substances contained in raw materials of plant origin can withstand high temperatures. For example, most water-soluble vitamins (C, B1, B5, B9, etc.) are quickly destroyed by heat treatment. The method of vacuum extraction of plant materials allows processing plants in the low-temperature range of 40-50 ° C, which eliminates the possibility of decomposition of thermolabile substances, and also accelerates the extraction of difficult to access biologically active substances.

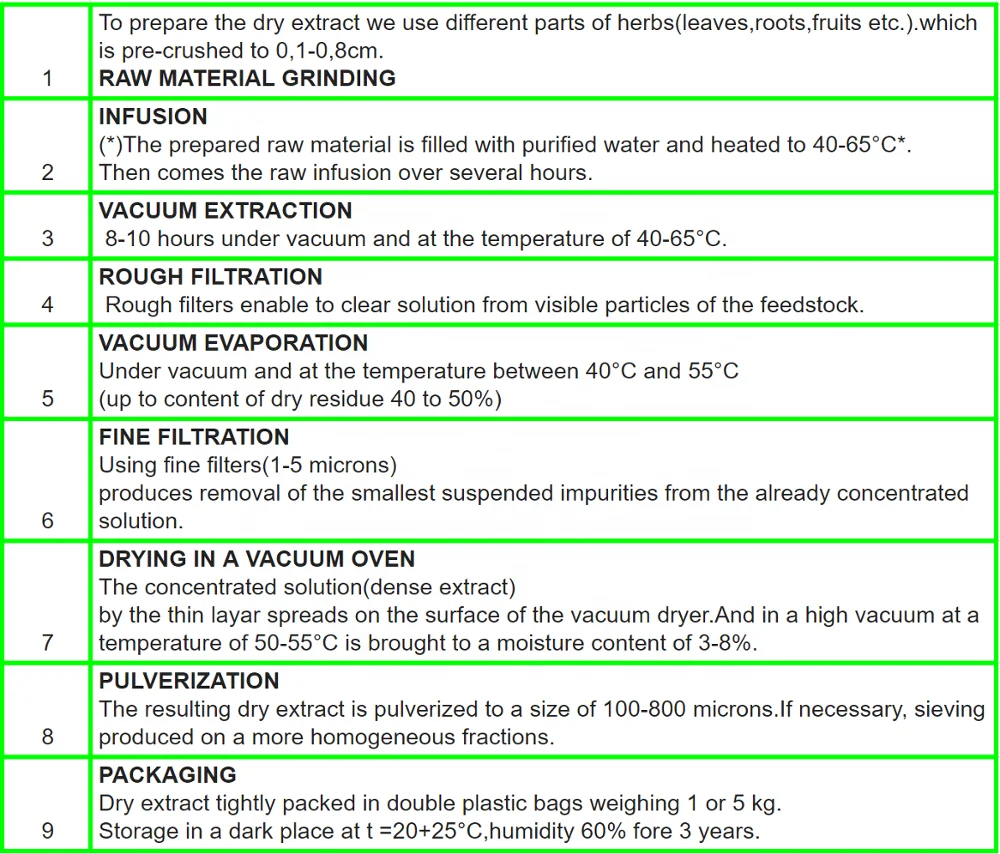

Processing of medicinal plant materials includes the following main stages:

raw material preparation,

infusion,

vacuum circulation extraction

cleaning

vacuum evaporation

fine filtration,

drying in vacuum cabinets.

The process of extracting active substances from dry plant materials is rather complicated. Some of the biologically active substances are in the feed in a dissolved state inside the cells, and some of the cell walls. Therefore, when extracting plant materials, it is important that the selected solvent (extractant) penetrates the pores and dissolves the necessary substances. After which there is already a mass transfer of substances into the bulk of the extracting liquid.

The speed and completeness of the release of biologically active substances during the processing of grass by vacuum extraction are influenced by factors such as:

standard plant material;

the structure of plant materials used;

degree of grinding;

type of extractant;

the ratio of "raw material-extractant";

temperature condition;

vacuum depth;

duration of extraction;

hydrodynamic conditions.

we purchase dry raw materials of plant origin, grown in ecologically clean areas, including the Altai Territory and Gorny Altai, which has the relevant documents confirming its quality.

The preparation of raw materials includes such steps as authentication, grinding, determination of moisture and extractives.

For each type of grass, we determined the optimal grinding fraction, which determines the size of the extraction surface. In our plant processing technology, water is used as an extractant, since it has good penetration through cell walls; possesses pharmacological indifference; It is a universal solvent and extractant. For the production of dry plant extracts, purified water is used that meets the requirements of current GOSTs, rules, and regulations.

The technological cycle for extracting plant materials is carried out at a vacuum depth of 0.1-0.2 kg / cm2 for several hours. The selected parameters provide the optimal ratio of indicators "extract yield" and "completeness and balance of biologically active substances." At the end of the extrusion stage, the extracted liquid is filtered through a bag filter, and then it is concentrated in a vacuum evaporator (to a solids content of 40%). After drying the condensed extract in a vacuum spraying unit, the residual moisture level in the final product is not more than 5%, which meets the requirements for dry extracts.

Qualitative and quantitative analysis of biologically active substances in raw materials and finished extracts obtained after the vacuum processing of medicinal herbs is carried out using high-performance liquid chromatography and spectrophotometers.

Dry water-soluble extracts obtained as a result of vacuum processing of plant materials have several advantages:

dry extracts retain almost the entire original vitamin composition;

have an average volume of 10 times less than the feedstock, which is important for storage and transportation;

the shelf life of the extract is at least 2 years;

purified water is used as an extractant, harmless to the health of children and persons with alcohol dependence;

extracts are a ready-to-eat product and can also be packaged in food capsules, converted into tablets, effervescent drinks and other products;

extracts are the raw material base for the production of medicines and cosmetic

| \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t |

Похожие товары

Экономичный Огнетушитель из углеродистой стали Iso, газ, Co2 Огнетушитель 5 кг

Сделанные на заказ штаны для кикбоксинга, для тренировок в тренажерном зале, обслуживание OEM, лучший стиль, профессиональный легкий вес

WEBETTER персонализированный киоск для пищевых продуктов Airstream мобильный фургон трейлер продажи

Нестандартный фланец из нержавеющей стали 310S для производства произвольного материала SR 316Ti

Лучшее качество, легкая очистка, Спеченный камень для кухонной столешницы

Теплоизоляционное одеяло из алюминиевой фольги теплоотражающая Нетканая алюминиевая

Ручной Волоконно-лазерный сварочный аппарат 1000 Вт/волоконно-лазерный сварочный аппарат из нержавеющей стали для лазерной пайки

Новые поступления

Новинки товаров от производителей по оптовым ценам