Скрытый совместный изолированный стоячий шов eps крыша панель для сборного

- Категория: Сэндвич-панели >>>

- Поставщик: Shandong Hengjia Haya Building Materials Ltd.

Сохранить в закладки 62443623172:

Описание и отзывы

Характеристики

| Name | Hidden joint insulated standing seam eps roof panel for prefab house |

| Outer layer | color steel sheet |

| Steel sheet thickness | 0.16-1.2mm |

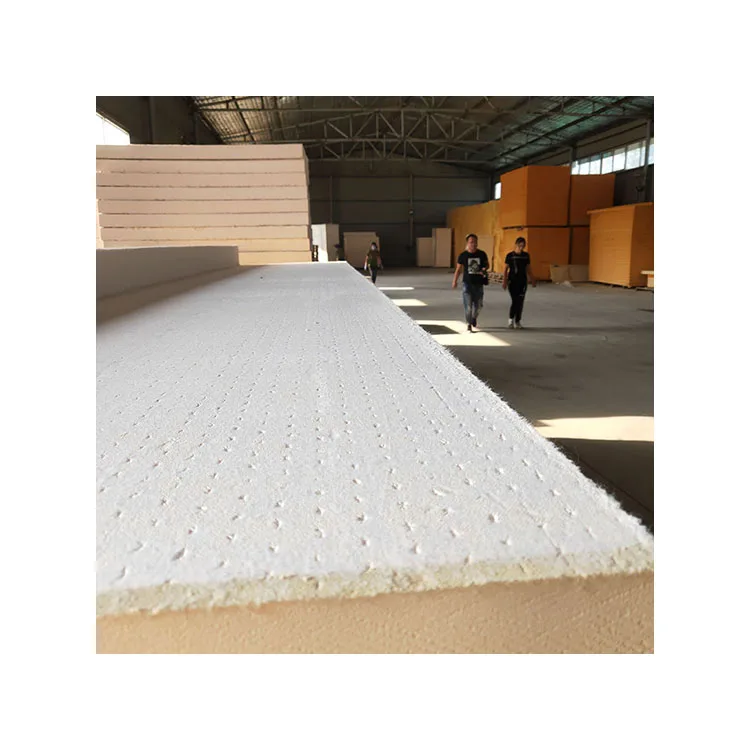

| Core | EPS board |

| EPS thickness(mm) | 50-150 |

| Density of Core | 4-20kg/m*m*m |

| Effictive width(mm) | 950,970 |

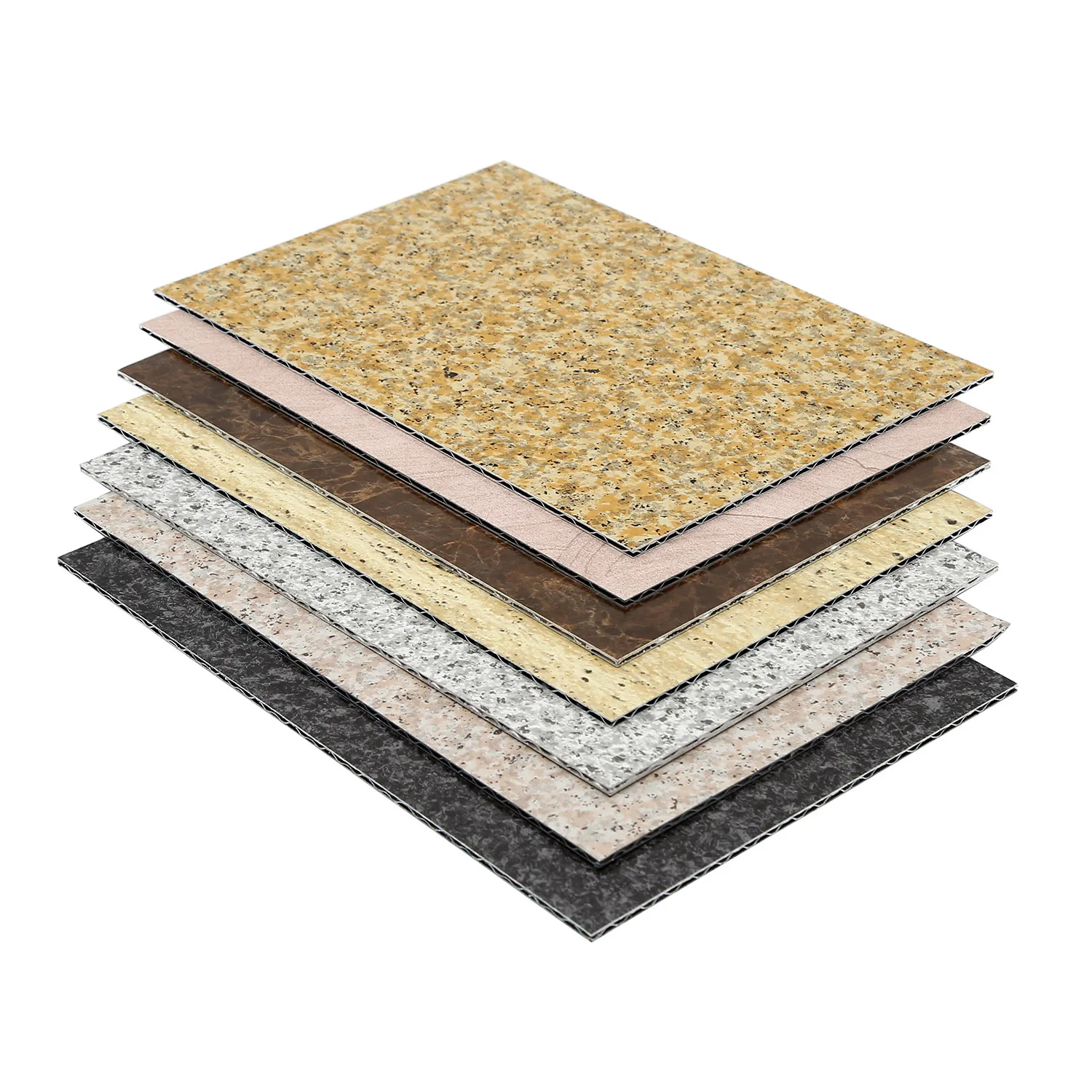

| Color | Customized |

| Length | As your requirement |

| Features | Lower price and best quality,Light in weight,easy to install |

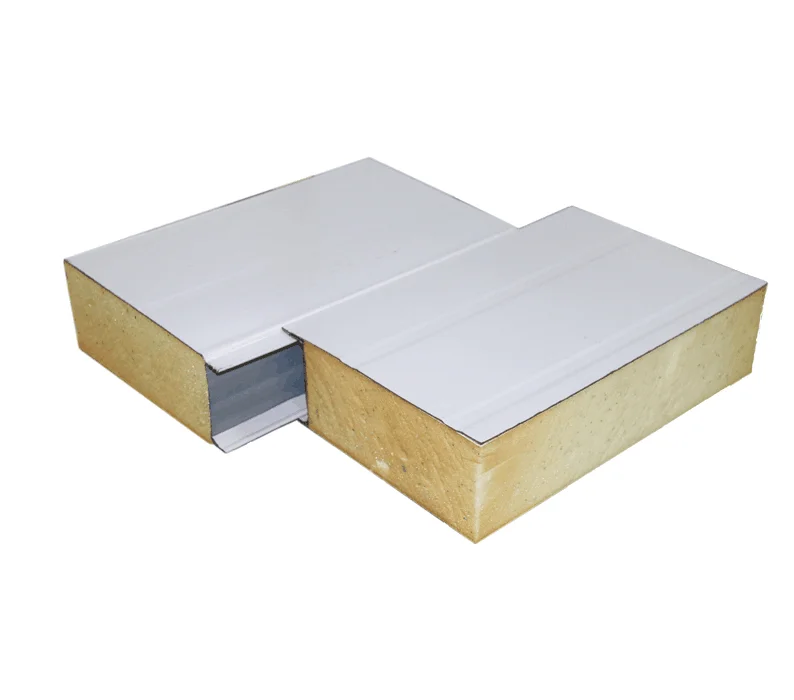

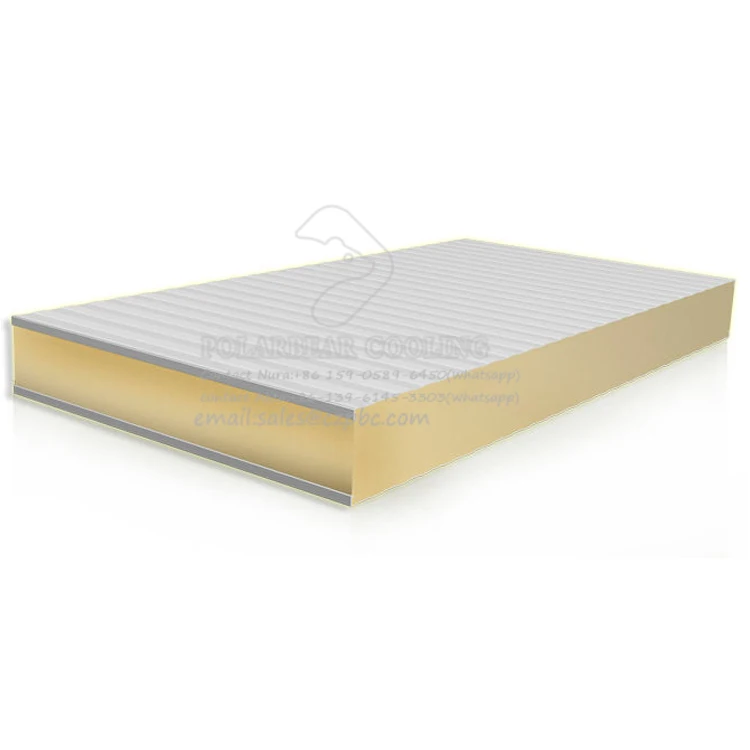

Sandwich panel looks like sandwich. Two external surfaces are made of prepainted corrugated steel sheets. And insulation materials usually use EPS, Glasswool, PU, Rock wool, etc.Hidden joint insulated standing seam eps roof panel for prefab house

Steel sandwich panel is consist of two layers of steel and insulating metarial such as polyurethane, rock wool, and eps.

Hidden joint insulated standing seam eps roof panel for prefab house

Features of EPS Sandwich Panel:

Hidden joint insulated standing seam eps roof panel for prefab house

1.Our EPS sandwich panel has the following characteristics:light weight, high mechanical strength, excellent shearing resistant performance, strong corrosion resistance, high durability, and weather fastness, etc.

Hidden joint insulated standing seam eps roof panel for prefab house

2. The sandwich panel has excellent insulating performance: heat insulation, sound insulation, waterproof performance, etc.

3. It is easy to install and can be used many times over.

4. Nowadays, the EPS sandwich panel is widely used for cleaning workshops, industrial factory buildings, office buildings, stadiums, villas, and public buildings, etc.

Apart from EPS sandwich panels, We also offers rock wool sandwich panels, glass wool sandwich panels, PU sandwich panels.

They are widely used in clean room as non-force bearing wall, roof and ceiling and as force bearing wall in single-storey prefabricated buildings. The major application demonstrates in the clean room system as partitions & ceilings.The fields range from electronics to semi-conductor, pharmaceutical, bio-tech and food processing etc.

Sandwich panel is a structure made of three layers: low density core inserted in between two relatively thin skin layers. This sandwich setup allows to achieve excellent mechanical performance at minimal weight. The very high rigidity of a sandwich panel is achieved thanks to interaction of its components under flexural load applied to the panel: core takes the shear loads and creates a distance between the skins which take the in-plane stresses, one skin in tension, the other in compression. General information on sandwich panel structure, different sandwich core types available and the potential with respect to weight savings is available in the following reference.

Packing:1,standard export package or as per customer's request

2,standard size containers,20'GP,40'GP or as per customer's request.

Похожие товары

Горизонтальная установка Изолированная EPS сэндвич-панель

Polyiso пенопластовая изоляционная панель пик огнестойкая

50 мм 75 100 сэндвич-панель из каменной ваты настенная панель для чистых

А2 противопожарная алюминиевая композитная панель для наружной стены Acp Pvdf наружная

Гелевое покрытие GRP FRP PP сотовые сэндвич-панели для кузова грузовика и стеновых

Заводская поставка, полиуретановая сэндвич-панель разного размера, водонепроницаемая панель для салетов, каменные наружные стеновые панели

Огнестойкая феноловая сэндвич-панель для беспыльной

Новые поступления

Новинки товаров от производителей по оптовым ценам