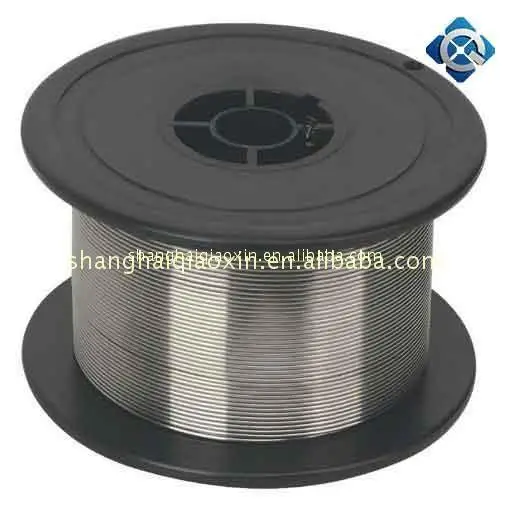

Qiaoxin никелевый сплав 28 проводов высокотемпературный nimonic 90 для продажи

- Категория: >>>

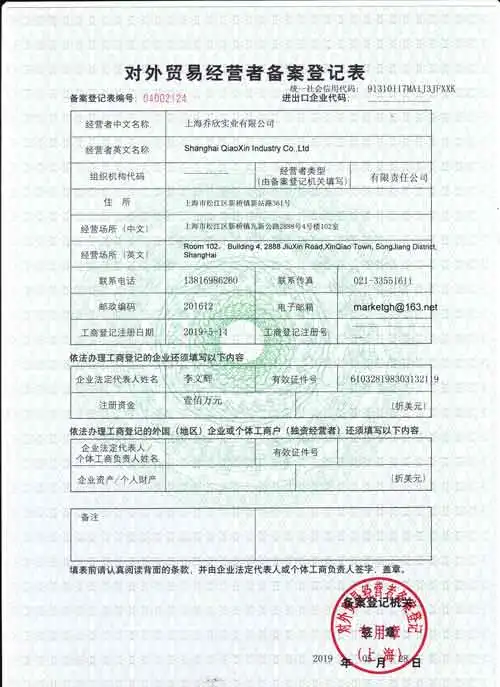

- Поставщик: Shanghai Qiaoxin Industry Co. Ltd.

Сохранить в закладки 62446999787:

Описание и отзывы

Характеристики

Qiaoxin nickel alloy 28 wire high temperature nimonic 90 for sale

Product details

| Shape: | wire |

| Surface: | Bright |

| Density g/cm^3: | 8.2 |

| Melting point: | 1400℃ |

| Finish condition: | Soft ,anneled |

| Technology: | Rolling and Drawing |

| Treatment: | Hydrogen Annealing |

| Strength of extension: | 1300-1400 MPa |

| Material: | FeMn |

| Size: | T:0.01-5mm |

| Product Keywords | nickel alloy 28 wire,high temperature nimonic 90 wire,high temperature alloy nimonic 90 wire |

Product Introduce:

The Nimonic 90 is Nickel-Chromium-Cobalt alloy being precipitation hardenable, having high stress-rupture strength and creep resistance at high temperatures up to about 950oC (1740oF). It is widely used and a well proven alloy in high temperature conditions.

Product Chemical Components:

| Grade | % | Ni | Co | Cr | Fe | Zr | B | C | Mn | Si | S | P | Cu | Ai | Ti |

| Nimonic90 | Min | Rest | 15.0 | 18.0 | - | - | - | - | - | - | - | - | - | 1.0 | 2.0 |

| Max | 21.0 | 21.0 | 1.5 | 0.15 | 0.02 | 0.13 | 0.4 | 0.8 | 0.015 | 0.02 | 0.2 | 2.0 | 3.0 |

Product Mechanical Properties:

| Heat Treatment | Tensile Strength(σb/MPa) | Yield Strength(σp0.2/MPa) | Elongation(σ5 /%) |

| Solution Treatment | 820 | 590 | 8 |

Product Application Fields && Available Size:

This alloy is used for turbing blades, discs, forgings, ring sections, hot-working tools and high-temperature springs.

Product Available Size:

Wires: Diameter0.5~7.5mm

Rods: Diameter8.0~200mm

Strip: Thickness0.5~2.5mm, Width5~180mm

Plate: Customized

Tube: Customized

ABOUT US

CUITURE

We cooperate with more than 30 domestic factories, straight for the products for us.Our cooperation factory has more than 15 years experience in production technology .We mainly operate metallic titanium and titanium alloy materials. We are a professional manufacturer for processing and producing metallic titanium, as well as titanium alloy materials. We are known for advanced processing technology, strong technical force, excellent quality, prompt delivery, and high credibility. We have complete production lines of bar materials: forging, rolling, grinding, and machining. We are able to achieve large-scale production of different thicknesses, different scales, different varieties and different specifications for different requirements of bars. We are able to use different classifications for production process.

Company Certificate:

PACKAGE:

Standard export carton packing or as according to customer`s requirement.

DELIVERY TIME:

3-20 days after confirming order,detail delivery date should be decided according to

production season and order quantity.

Похожие товары

SUS410 Самонарезающий винт с плоской головкой, может предложить вам высокое качество самосверлящие винт/оцинкованные винты, увенчанные

Бикарбонат натрия, бикарбонат соды для приготовления пищи

Ручная и Автоматическая Пожарная безопасность оборудование для пешеходного доступа ворота автоматический турникет с функцией сигнализации

63a Iec 62196-2 Входная розетка для электромобиля/соединитель типа 2

Лучший хьюмидор, коробка для сигар, аксессуары, деревянный хьюмидор для сигар с шкафчиками, портативный, для путешествий

100% натуральная деревянная ручная работа, лучший деревянный продукт для курения табака

Черный или коричневый индивидуальный цвет сигара + кожаный чехол для путешествий сигар коробка для сигарет из искусственной кожи хороший подарок курильщик

Новые поступления

Новинки товаров от производителей по оптовым ценам