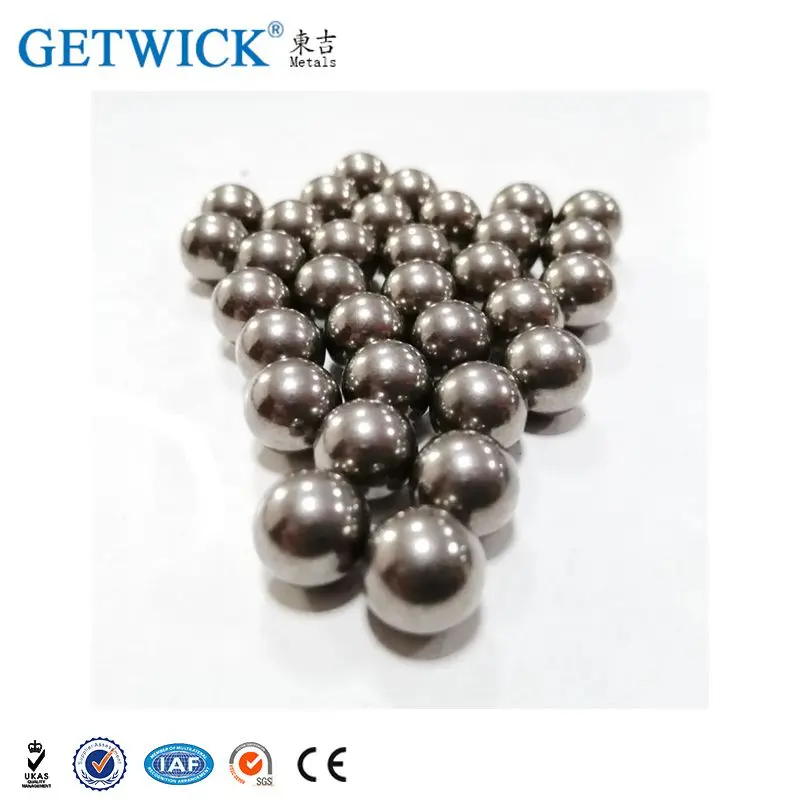

Вольфрамовый карбидный сплав масляный клапан шаровой керамический

- Категория: >>>

- Поставщик: Zigong Zhaoqiang Sealing Products Industrial Co. Ltd.

Сохранить в закладки 62453669174:

Описание и отзывы

Характеристики

Product Description

Tungsten Carbide Valve Ball Material Grade Specification:

| Grade | Density (g/cm3) | Typical Value | Application Scope | |

| Hardness | Bending Strength | |||

| YG3 | 15.10~15.30 | 92.5 | 1700 | Superior wear resistance only less than YG3X, sensitive to impact and vibration, suitable for cast non-ferrous metal and its alloy finish turning, semi-finish turning, thread finish turning and hole expanding. |

| YG3X | 15.10~15.30 | 93.6 | 1450 | Best wear resistance in Tungeten and Cobalt alooy, but not good in anti-impact proprety, suitable for cast iron, non-ferrous and alloy, quenched steel, alloy steel small cutting section machining at high speed. |

| YG6X | 14.80~15.00 | 92.4 | 2000 | Belong to small granule Tungsten carbide alloy, wear resistance higher than YG6. Suitable for machining cold and hard alloy cast iron and heat resistance alloy steel, as well as finish machiing for normal cast iron. |

| YG6 | 14.80~15.00 | 91.1 | 2100 | High wear resistance but less than YG3, better anti-impact and anti-vibration than YG3X, Suitable for cast iron, non-ferrous and alloy, non-metal material semi-finish machining and finish machining. |

| YG6A | 14.8~15.00 | 92.8 | 1850 | Belong to small granule alloy, wear resistance hig, suitable for semi-finish machining of cold and hard cast iron, non-ferrous and alloy, as well as semi-finish machining and finish machining for quenched steel, alloy steel |

| YG8 | 14.6~14.80 | 90.5 | 2300 | High bending strength resistance, better anti-impact and anti-vibration than YG6, suitable for cast iron, non-ferrous and alloy, non-metal material rough machining at low speed. |

| YG522 | 14.20~14.40 | 92.5 | 2000 | High wear resistance, and high strength, special grade for bamboo and wood processing, also suitable for non-ferrous and non-metal material cutting process. |

| YG546 | 14.55~14.75 | 90.5 | 2700 | High flexibility and high strength, withstand high impact load, suitable for stainless steel and cast iron rough processing |

| YG610 | 14.60~14.80 | 93.5 | 2000 | High wear resistance and high hardness, suitable for cast iron, high temperature alloy, quenched material cutting continuous and discontinuously. |

| YG640 | 13.10~13.30 | 91.5 | 2300 | Impact resistance and anti-oxidant, suitable for large cast piece cutting continuous and discontinuously, and anti-heat steel, high strength steel milling and digging. |

| YG643 | 13.60~13.80 | 93.3 | 1700 | High wear resistance, high anti-stick property, suitable for cast iron, high temperature cast iron, high temperature alloy, stainless steel, quenched steel and non-ferrous processing. |

| YG813 | 14.30~14.50 | 92 | 2200 | Good wear resistance, high bending strength resistance and anti-stick property, suitable for processing high temperature alloy, stainless steel and high Manganese steel and other material. |

Company Information

Zigong Zhaoqiang Sealing Products Industrial Co.,Ltd is a professional manufacturer of mechanical seals and wear-resistant materials, which has 20 years of experience in designing and manufacturing these products.

With good quality products, competitive prices and excellent services, we have won a good reputation among customers at home and abroad. And it's our pleasure to find a way to cooperate with you!

Packaging & Shipping

FAQ

FAQ

| Q1 | Are you a factory or a trading company? |

| A | We are a professional factory with 20 years of experience in designing and manufacturing mechanical seals and wear-resistant materials. |

| Q2 | Can I get an sample to check the quality of products? |

| A | Yes. We can send you samples to check the quality within 3-5days. |

| Q3 | Do you provide free samples? |

| A | We can provide free samples, but you need to pay for the freight to your destination. |

| Q4 | What payment terms do you accept? |

| A | We accept T/T, Western Union, Paypal and Escrow, L/C, etc. |

| Q5 | I can not find our products in your catalog. Can you make customized products for us? |

| A | Yes. Customized products are available according to your drawings or working conditions. |

| Q6 | Could you design it if I don’t have drawings or pictures for custom products? |

| A | Yes,we can make the best suitable design in accordance with your application and working conditions. |

Contact us

International Trade Department

Winnie Xu

Mobile: +86-18695952621

WeChat: +86-18695952621

Website: www.zg-zqseal.com

Похожие товары

Изготовленные на заказ однократные полиуретановые материалы для литья Пластика под давлением полиуретановые детали для всех машин

BPA бесплатные силиконовые лоток коврик по индивидуальному заказу детские обеденный стол место для полукруг в форме Нескользящие теплостойкая Силиконовая Подставка для столовых приборов

2,92 $ - 3,14 $

Изготовление зубных с шариковым носиком и заусенцев, вольфрам-Карбидное роторное боры

Карбидный вольфрамовый шар 3,5 мм, полированный вольфрамовый шар

0,25 $ - 0,30 $

Цветные мягкие пряди из натуральной кожи по оптовой цене завода-изготовителя

19,00 $ - 28,00 $

HTCC-5 катализатор окисления углеводородного водорода

11 111 111,00 $

Аксессуары для мотоциклов gy6 125 cc масляный радиатор

8,50 $ - 10,80 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $