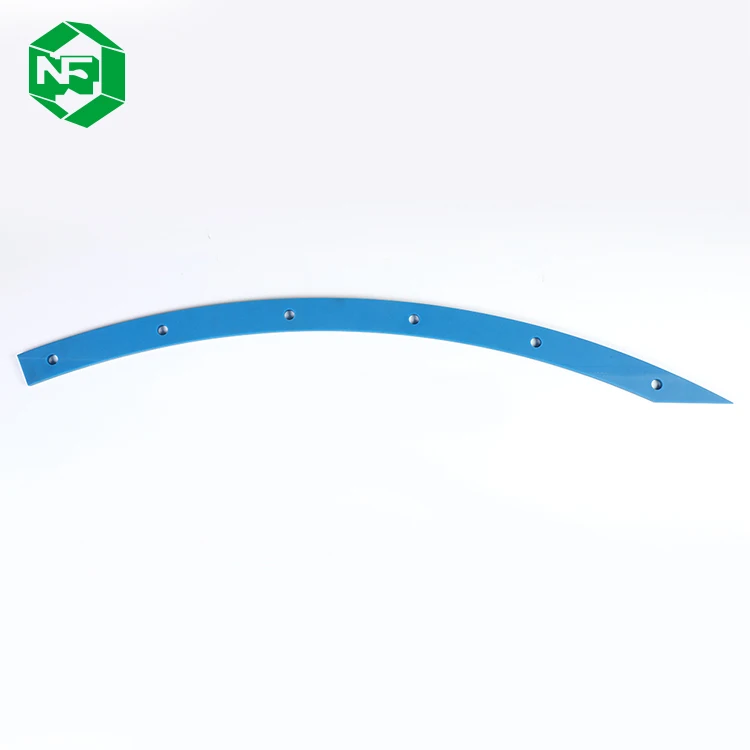

Износостойкий конвейер боковая направляющая для литья обработанные синие пластиковые направляющие цепи

- Категория: >>>

- Поставщик: Guangdong Nanfang Nylon Products Co. Ltd.

Сохранить в закладки 62459772451:

Описание и отзывы

Характеристики

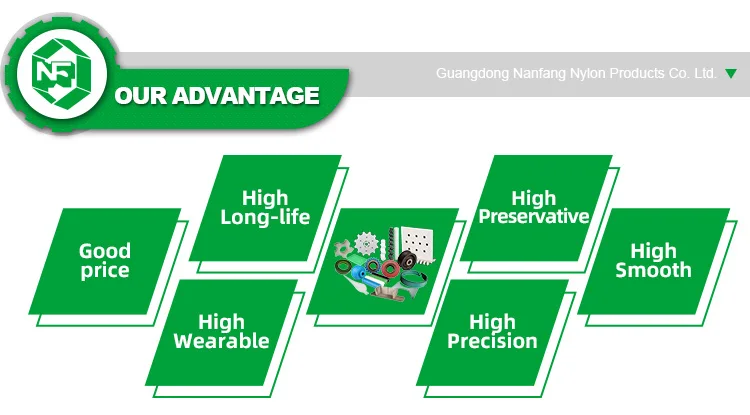

Guangdong Nanfang Nylon Products Co. Ltd. , established in 1988 , is a professional production of "Engineering plastics accessories" high tech enterprises . Company have a complete set of imported production equipment and numerical control processing equipments .

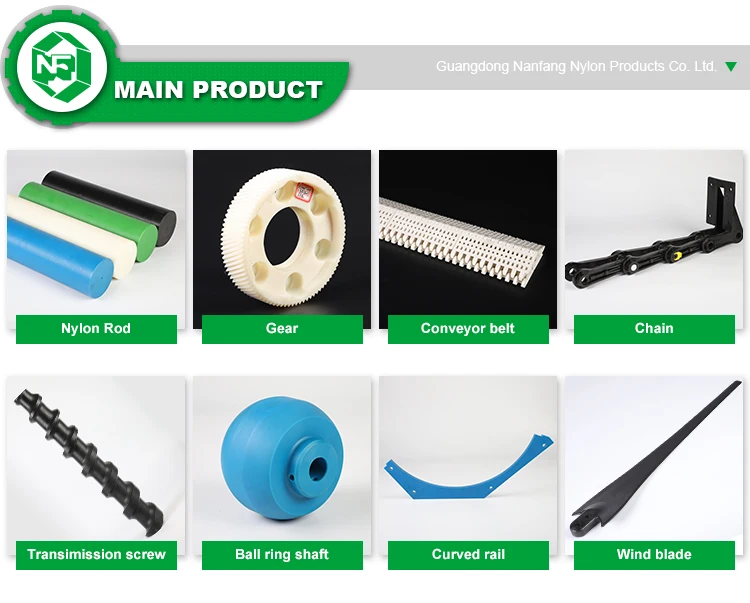

Company main products are : UHMW-PE , MC Nylon , PA6, POM , HDPE , ABS , PU , PC , PVC , PP ,PET, PBT , Acrylic , PEEK PPS, PTFE , PVDF , PAI , PEI , PSU , PI , PBI, Antistatic product series . Copnay strictly enforce ISO9001 international quality certification system.

| Products | Guide | Weight | 30mm |

| Type | Transmission accessories | Length | 680mm |

| Material | MC oily nylon | Thickness | 5mm |

| Technology | Casting | Shape | Bending,straight line |

| Color | Black, green, Blue | Brand | Nanfang Nylon |

| Feature | 1. Excellent abrasion resistance, 2. Good toughness, 3. Stable material performance 4. Insulation and environmental protection | Application | Packaging machinery and paper-making machinery |

Guangdong Nanfang Nylon Products Co. Ltd. is a polymer parts producer based in Foshan, China, found in1988.With decades of experience dealing with polymer material, every aspect of producing a part is considered.

Guangdong Nanfang Nylon Products Co. Ltd. is a polymer parts producer based in Foshan, China, found in1988.With decades of experience dealing with polymer material, every aspect of producing a part is considered.

The company is committed to manufacture the highest class parts possible, striving to not only meet the requirements of the print, but also making parts that are clean with minimal tooling marks.

Within the factory, the production is run by four workshops, machinery processing shop, injection molding shop, mold shop and material synthesis shop.

As the biggest workshop in the factory, the machinery processing shop has a full set of equipment, such as: lathe, mill,sawing machine, grinding machine, water-jet cutting machine and HAAS CNC from the US. Almost all processes can be done in the workshop with well control.

As the biggest workshop in the factory, the machinery processing shop has a full set of equipment, such as: lathe, mill,sawing machine, grinding machine, water-jet cutting machine and HAAS CNC from the US. Almost all processes can be done in the workshop with well control.

For high volume production, injection molding is the best option. The biggest injection molding machine in shop, has aclamping force of 560 tons, with maximum injection weight of 2 kilograms.

Departing from the machinery processing shop, mold shop is mainly responsible for the production and maintenance of the mold. Offering the strongest backup to the injection molding shop.Full in-house quality check devices can guarantee the parts are built to our customer's specification.

Похожие товары

Дешевая индивидуальная круглая коробка, профессиональный производитель, Упаковочная Цилиндрическая Коробка, черная подарочная коробка

Оптовая продажа от производителя, индивидуальные круглые коробки для упаковки шоколадных конфет, с бумажным мешком

Детские развивающие игрушки «сделай сам», Лидер продаж, войлочные игрушки «сделай сам», индивидуальные Семейные игрушки «сделай сам» для детей

(Активные компоненты) CH2-MD12F

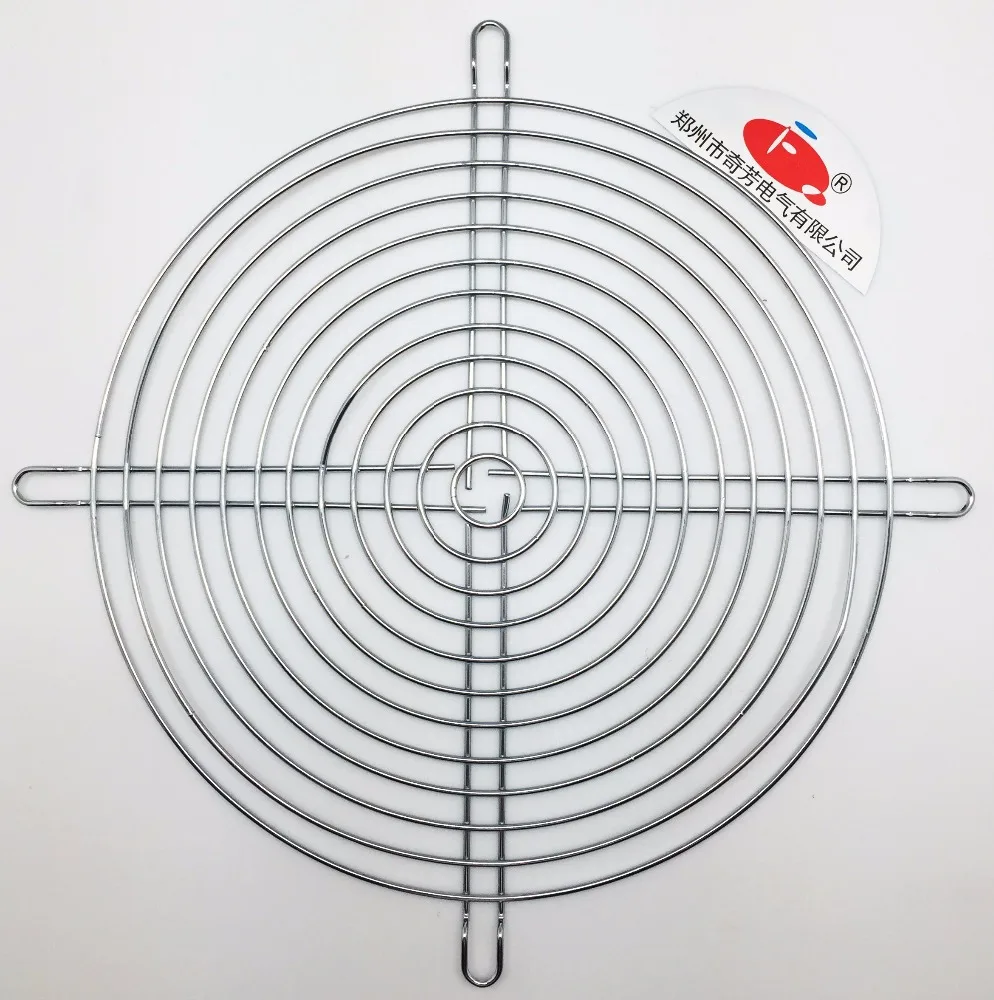

Металлический Стальной сетчатый кожух 60 мм, 90 мм, 200 мм, кожух охлаждающего вентилятора в наличии

Китайский производитель, картонная коробка на заказ, Подарочная коробка, индивидуальный бумажный логотип, печатные фрукты, вишни, коробки для доставки

Роскошный индивидуальный логотип от производителя, премиум картонная бумага, большая круглая упаковка, элегантные ювелирные изделия, круглая необычная плоская подарочная коробка

Новые поступления

Новинки товаров от производителей по оптовым ценам