2 м х 1 3 перерабатываемая ПП пенная доска с высоким качеством для коробки лайнера

- Категория: >>>

- Поставщик: Changzhou Songyu New Material Co. Ltd.

Сохранить в закладки 62480604021:

Описание и отзывы

Характеристики

1.Product Overview

Our micro-cellular materials were produced by the foaming of polymers PP with advanced super-critical carbon dioxide technology. These materials have highly consistent cell structure and the advantages of clean and green, non cross-linked, no toxic residues, thermal bonding, safety and environmental protection, recyclable and degradable. Microcellular PP foam materials such as JBKH could be applied as product packaging, as they are lightweight, closed cell, low flammability, no odour, long life durability and resilient and elastic.

Product name | JBKH-10,JBKH-15,JBKH-20,JBKH-25 |

Foam Material | Polypropylene (PP) |

Color | White(Customized) |

Thickness | 10mm~60mm |

Dimension | 2.2mx1.3m; 2.3mx1.5m; 2.6mx1.6m; 2.8mx1.7m |

Density | 36~90 kg/m3 |

Processing Method | Physical Method, N2 or CO2 as foam agent without any chemical additives |

Production Capability | 1200~2400 ton/year |

Special Feature | Eco friendly, Recycle,No toxic, resilient, high strength |

Usage Fields | Product packaging |

2.Product Advantage

Butane, fluoride, AC foaming agent and other substances harmful to the environment are not used in the production process by making full use of the independently developed physical supercritical carbon dioxide foaming technology. JBKH is a high performance foams with highly consistent cell structure based on PP and contains no toxic or volatile chemicals and no form-amide residues.

Our high-quality foams with their native born characteristics of lightweight, no-toxic , ordourless, heat resistant, non-conductive, anti-corrosion or staining, low flammability, long life durability and resilient and elastic are an ideal geen and recycling material for the luxury, FMCG, artwork and electronic packaging.

Our foams have the characteristic of high strength, hardness and good hydrophobicity. The experimental results show that our products have excellent physical performance and are better than the traditional materials.

Micro-cellular materials were produced by the foaming processing of polymers(PP) with advanced super-critical carbon dioxide method. First, Solid base boards are impregnated with CO2 or N2 in a certain environment of high pressure and elevated temperature. Second, the solid sheet will be expanded into the foam material with closed cell structure in lower pressure autoclave. Finally the the foam material will be cutted by the machine as pp foam sheet or board.

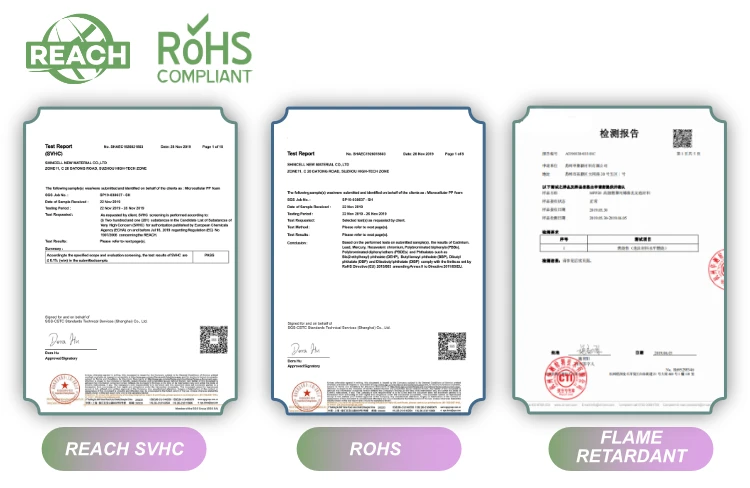

Flame retardant of the Microcellular pp foam has passed the test by the authority. Our foam products also have passed authoritative certification of RoHS. These testing reports are shown in the following picture.

Our company has complete automatic production line which can produce new micro-cellular foam Board/Sheet/Film and foam particle according to the customer's requirements. Improving production efficiency and saving energy are always as our first condition of production process. We are always preparing to provide high quality service to customers.

Q 1. What is the normal lead time for product?

A: Average lead times for prototype / first article are 1-2 weeks, if tooling is involved, lead time for production tooling is 10 days, average production time after sample approval is 2-3 weeks.

Q 2. What is your packing standard?

A: All the goods will be packed by carton box with plastic bags and loaded with pallets

Q3. What is your sample policy?

A: Free samples are available with small amount,you should pay for the express fee, if you need,Please feel free to contact us.

Q 4:Can you supply different color materials?

A: Yes, we can produce customized products in different colors, the color code will be required in case of an order.

Q 5: What materials are available to produce from your side?

A: PP, TPU, TPE, PA6 etc.

Похожие товары

Комнатный полноцветный маленький светодиодный дисплей P2.5, рекламный светодиодный постер с колесами

Формиат натрия sliquor HCOONa 141-53-7 SG1.3 от надежного производителя

Ограниченная плитка для пола/плитки автомобильной парковки/напольная

Лидер продаж мочеприемники для домашних животных поглощающие подушечки собак одноразовые товары домашнего

Ethernet медиа конвертер Gigabit 10/100/1000M RJ45 волоконно-оптический конвертер 2 км

Покупайте на линии, ювелирный спектрометр Рамана, ручной измеритель драгоценных металлов

Натуральный фруктовый концентрат Lo Han Guo, Обесцвечивающий экстракт могрозида V 20%, белый порошок

Новые поступления

Новинки товаров от производителей по оптовым ценам