Емкость для хранения из нержавеющей стали полированная емкость смешивания большой емкости подготовки

- Категория: Pressure Vessels >>>

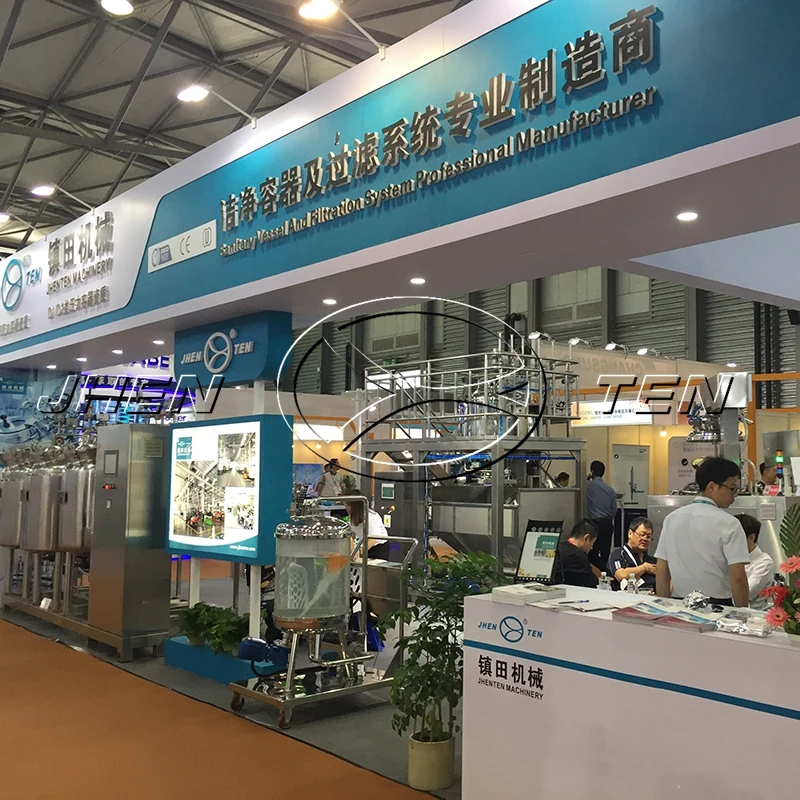

- Поставщик: Zhejiang Jhen Ten Machinery Co. Ltd.

Сохранить в закладки 62483774491:

Описание и отзывы

Характеристики

Stainless steel polished large capacity mixing storage tank, liquid preparation vessel

Introduction:

Liquid preparation vessel is for making base liquids before final reaction.

Usually it has an agitator and a jacket outside for input conduction oil.

The oil is heated by electric rods. There are oil inlet, outlet, overflow port, vent port, electric rods port,

and temperature detection port on the jacket.

Features:

1. SS material, can bear high pressure during the process of materials reaction and feeding

2. Good heat-resistance, large range of working temperature (-196~600°C).

3. Good anti-corrosion, not easily get rust

4. Good heat transfer

5. Mirror polish, easy clean without residuals

Specs. Of 500 L. Preparation Vessel (Jhenten)

1- Material of TANK : SUS316L

2- Thickness of shell: 4 -6 mm

3- Working pressure: -1 to 4 Bar

4- Working Capacity Of the Vessel is 500 Liters

5- Working temperature: 121°C

6- Design Temp : minimum 10°C & maximum around 150°C

7-Motor power: 1.5KW 380V 60Hz horizontal type

8- Agitator Speed : 70 – 90 RPM & Agitator type : 2Layers

9-Diameter of TANK: 800mm - 1000mm

10- Height from Floor to Motor Top Of the Agitator =1500 mm

1-Material of heat preservation layer:SUS304 thickness: 3 -5 mm

12- Polishing From Inner Side is Mirror 0.28μm

13.-Polishing From Outer Side is Mirror not more than 0.5μm

14- TWO Rotating Balls ST.ST.316 L inside the Tank For Cleaning

15- At The Tank Bottom We Need Diaphragm Valve With Triclamp Connection

16- Connections ( 316L Triclamp Connections ) for CIP, SIP, Product Circulation + Pressure gauge + Air Filter,Connection + Safety Valve ( All 1.5 Inch )

17- Sight Glass With suitable Effective Light

18- Man Hole LID with Silicon OR EPDM O ring & Open towards the Agitator motor Side

19- Design & Manufacturing Qualification Document, include Official Certificates Of Tank Materials & Tank Welding Certificates

20- Factory Acceptance Tests ( FAT ) Documents

21- Site Acceptance Test ( SAT ) Documents

22- Installation Qualification Documents ( IQ ) & Operation Qualification Documents (OQ )

23- Grantee Certificate

Main Technical parameters

Parameter | ZT 300 | ZT400 | ZT500 | ZT600 | ZT1000 | ZT2000 | ZT3000 | ZT5000 | ZT10000 | ||||||||||||

Cubage(L) | 300 | 400 | 500 | 600 | 1000 | 2000 | 3000 | 5000 | 10000 | ||||||||||||

Pressure | Internal bladder | ≤ 0.2Mpa | |||||||||||||||||||

Insert set | ≤ 0.3Mpa | ||||||||||||||||||||

Power (Kw) | 0.55 | 0.55 | 0.75 | 0.75 | 1.1 | 1.5 | 1.5 | 2.2 | 3 | ||||||||||||

Speed of impeller | 18=200r/min | ||||||||||||||||||||

Outlook size | Diameter | 900 | 1000 | 1150 | 1150 | 1400 | 1580 | 1800 | 2050 | 2500 | |||||||||||

Height | 2200 | 2220 | 2400 | 2500 | 2700 | 3300 | 3600 | 4200 | 5000 | ||||||||||||

Heat transfer area | 2 | 2.4 | 2.7 | 3.1 | 4.5 | 7.5 | 8.6 | 10.4 | 20.2 | ||||||||||||

Q: CAN I HAVE SAMPLES TO TEST?

A: Yes, we are pleased to supply samples to test and check quality, miled sample order is available. Please note, free samples is not acceptable.

Q: DO YOU HAVE ANY MOQ LIMITED?

A: Our MOQ is 1PC to supply new customers.

Q: WHAT'S THE LEAD TIME?

A: Sample: 20-25days. Mass production: 25-30days depend on the order quantity.

Q: HOW DO YOU SHIP THE GOODS AND HOW LONG DOES IT TAKE?

A: We ususlly ship by sea. DHL, UPS, fedex TNT are also acceptable.

Похожие товары

Вакуумный упаковочный композитный Автоклав из углеродного волокна

Многофункциональный резервуар для хранения lpg объемом 250 м3 20000 литров ghana Нигерия многофункциональные резервуары

Бак для хранения газа Lox 5 м3 8

Новый сферический резервуар для хранения сжиженного углеводородного газа 2000 куб. М дизайн и установка от

Конденсаторные кастрюли высокого давления с внутренней резьбой NPT 6000 фунтов на квадратный дюйм 2 6

DP-6412H профессиональный ручной работы для Смешивания Краски бак 20L давления горшок с ручным перемешивающего

T-80L перемешивания передатчик напорного бака Автоматическая Машина Для Смешивания Краски Ведро пневматическим смешиванием Ведерко для краски

Новые поступления

Новинки товаров от производителей по оптовым ценам