1530 Высококачественная машина для резки алюминиевых композитных панелей воздушно плазменный резак плазменной металла

- Категория: >>>

- Поставщик: Jinan Knoppo Automation Equipment Co. Ltd.

Сохранить в закладки 62488200541:

Описание и отзывы

Характеристики

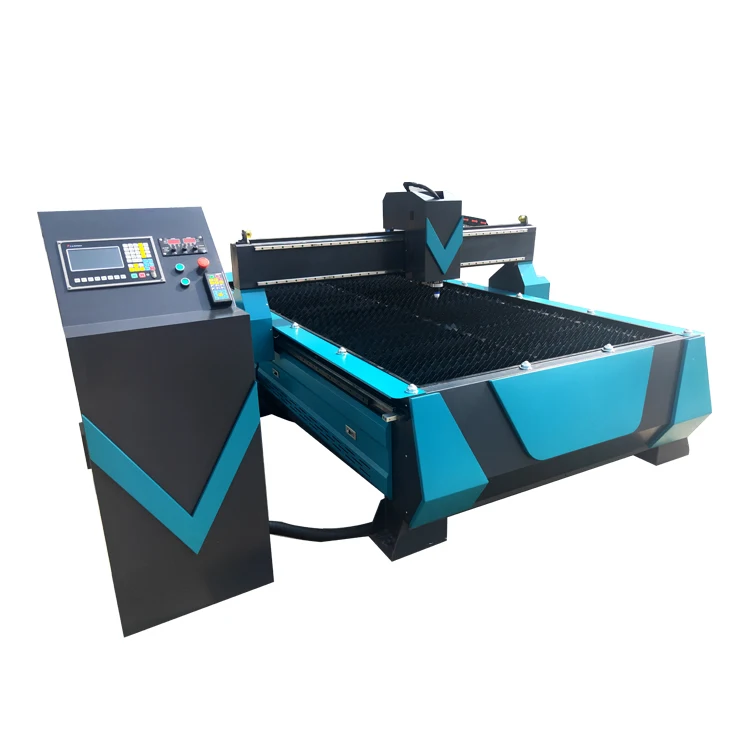

1530 High quality aluminum composite panel cutting machine, air plasma cutter, plasma cutting machine for metal

Product Description

The structure and configuration list

1. seamless welding machine body

2. 1500*3000mm working area

3. Independent control cabinet

4. STARfire control system

5. Automatic Torch height controller

6. Starcam software

7. 2GB processing file

8. high precision square guide rail

9. LGK63A Plasma

10.Leadshine servo motor

11.Multi-function tool box

12.Efficiency exhaust smoke system

13.Easy feeding slide material system

14.High quality soft electricity cable can be bend for 1.5 million times

15.15 sets of nozzle electrodes

16.All the necessary parts for machine working

17.Wireless control handle

18.Electromagnetic collision prevention function

2. 1500*3000mm working area

3. Independent control cabinet

4. STARfire control system

5. Automatic Torch height controller

6. Starcam software

7. 2GB processing file

8. high precision square guide rail

9. LGK63A Plasma

10.Leadshine servo motor

11.Multi-function tool box

12.Efficiency exhaust smoke system

13.Easy feeding slide material system

14.High quality soft electricity cable can be bend for 1.5 million times

15.15 sets of nozzle electrodes

16.All the necessary parts for machine working

17.Wireless control handle

18.Electromagnetic collision prevention function

19.Red light positioning function

20.Automatic oiling system

20.Automatic oiling system

X,Y working area | 1500*3000mm |

Z working area | 150mm |

Packing dimension | 2280mm*3850mm*1850mm |

Weight | 1600KG |

Machine bed | Very thick steel structure |

Machine power | 16kw |

Reposition precision | 0.02mm |

Processing precision | 0.1mm |

Maximum cutting speed | 12000mm/min |

Torch Height control mode | Automatic |

Cutting thickness | Max 30mm carbon steel |

Plasma power supply | 63A 100A 120A 160A 200A |

Control system | STARfire |

Motors | servo motor |

Software | Starcam |

Plasma Air Pressure | Max.0.8Mpa |

Working Temperature | -10°C-60°C. Relative Humidity, 0-95%. |

LCD Display Dimension | 7 Inches |

Detailed Images

LGK63A PLASMA

STARFIRE Microstep control

Automatic Torch height control

Software starcam

Independent control cabinet

Strong Machine body

2G processing file

Automatic oiling system

Wireless control handle

Electromagnetic collision prevention

Germany Rack

Leadshine servo motor

The advantages of our machine

①We do this line many years, have rich experience and professional knowledge, will let you get the most suitable machine with the right configuration. This ability can let you avoid many mistake and avoid some trouble. Other factory usually lack this experience, and bring some trouble for the real customer.

②If use the plasma cutting machine to cut the the thick meal, have to use the arc height adjust system, while our height adjust system use the high sensor, one minute can send out 12,000 signal per minute, while other height adjust system usually send out 10000 signal per minute, so our cutting quality more better than other factory and cutting speed a litter faster than the same power plasma source.

③we equipped the two fan for take the cutting smoke out from the room, front fan will blow to back, the back fan will exhaust the smoke out from the machine and out from the room. This way, will efficiency to let the workshop in the good environment. While other factory does not have this fan or only have one.

④ All our machines have to be checked three times, then allow to send out ,and finally will put one 8GB flash disk into the package, when the customer received the machine, can easy check the video from the 8GB flash disk ,then do the easy operation, in the video nearly like hand by hand do the teaching job, so can let the customer in the shot time to let the machine create the profit. While we also have the video platform, after you purchase the machine, we will give you one password, then you can easy to get the efficiency “after-sell service” from the internet. While other small factory usually, only check one time for the machine, and no 8GB flash disk, and no video platform, then it is hard for you to get the good after-sell service.

⑤we will free provide 2G processing design (USD 320) and Australia professional metal cutting software for you, in the 2G processing design have thousand beautiful graphic, after you get the machine, you can let the machine do a lot of beautiful work, while no need find the engineer to help you to design.

⑥Machine structure is designed by famous mechanical professor, to add many columns for each bean. So that the machine body can bear more weight for large, thick metal sheets without deforming. But some small factories will not add these parts for saving cost, their machine is easy to deform for thick metal.

Sample

Related Products

Packing&Shipping

After Sales Service

* 24 hours service * Training how to install this machine . * Training how to use this machine .

Company Introduction

Knoppo Automation is one of the world’s leading manufacturers of high-tech industrial laser solutions, dedicated to providinglaser intelligent equipment solutions and enabling our customers in various branches around the world to become more efficient andcompetitive. With more than 15,000 laser cutting systems in the market and a rapidly increasing global base, Knoppo Automation isin a favorable position to serve the international customer base, guaranteeing highest quality and shortest response times inalready more than 100 countries. Our focus is on the innovation, continuous improvement and rapid development of technologies, allof which aim to increase efficiencies and flexibility, minimize costs while generating the highest levels of environmentalfriendliness and sustainability to our all benefit. We aim to provide key technologies and customized integration solutions forIndustry 4.0 and smart factories, helping enterprises to make perfect use of the many opportunities arising in the digital age.

The product range not only comprises of flat sheet cutting systems in various designs and dimensions, but also of laser tubecutting systems, CO2 laser cutting engraving machine , laser marking machine etc . With our focused, highly skilled andexperienced R & D team and a perfectly equipped and trained systematic after-sales technical department, we truly provide customer-oriented service experience.

The product range not only comprises of flat sheet cutting systems in various designs and dimensions, but also of laser tubecutting systems, CO2 laser cutting engraving machine , laser marking machine etc . With our focused, highly skilled andexperienced R & D team and a perfectly equipped and trained systematic after-sales technical department, we truly provide customer-oriented service experience.

Contact Us

Похожие товары

ЧПУ Китай Сверхмощный металлический резак плазменной резки

2 800,00 $ - 3 000,00 $

Дешевая машина для плазменной резки железа с двойной рейкой

3 300,00 $

Резаки для воздушно-плазменной резки с ЧПУ из нержавеющей стали и алюминия

6 000,00 $ - 15 000,00 $

Воздуховод CNC машина для плазменной резки

5 600,00 $

Воздушный компрессор для машины плазменной резки 1530 cnc, машина плазменной резки 40 мм

4 500,00 $ - 6 000,00 $

Воздушный компрессор, плазменный резак для плазменной резки металла, 50 мм

5 695,52 $ - 6 296,35 $

Новое поступление, машина для резки воздуховодов, индивидуальная машина для плазменной резки металла с ЧПУ, быстрая резка и простота в эксплуатации

5 000,00 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

Рекламный надувной самолет украшение для костюма самолета ходячие костюмы продажи

C100 % восковая ткань с принтом китайские поставщики поставляют настраиваемые печатные африканские восковые ткани

0,93-0,97 $

Прямые продажи с фабрики могут быть оптовые складные тележки для покупок Удобные и уличные продуктовые

8,39-9,89 $

Hantek щупы осциллографа автоматический Тестовый Кабель Ht30a Bnc к банану двойная Банановая головка многоцелевое автомобильное

3,10-3,44 $

Горячая распродажа ручная работа традиционная деревянная урна для домашних животных квадратная коробка золы собак и кошек персонализированная Лучшая цена

Промышленная серия CL Бесшумная цепь стальная зубчатая Фланцевая контактная звездочка соединяющая бесшумные цепи

1-1,50 $

Irdmco экологически чистый минималистичный прямоугольный деревянный ящик для хранения стеллаж поделок и детских игрушек Домашняя мебель гостиной

Технология сенсорных перчаток и аксессуары для детей от дождя холода M725132-334

1,07-1,40 $