Ультратонкий заводской стеклянный

- Категория: Building & Industrial Glass >>>

- Поставщик: Jinan Zhaoyang Machine Co. Ltd.

Сохранить в закладки 62507918789:

Описание и отзывы

Характеристики

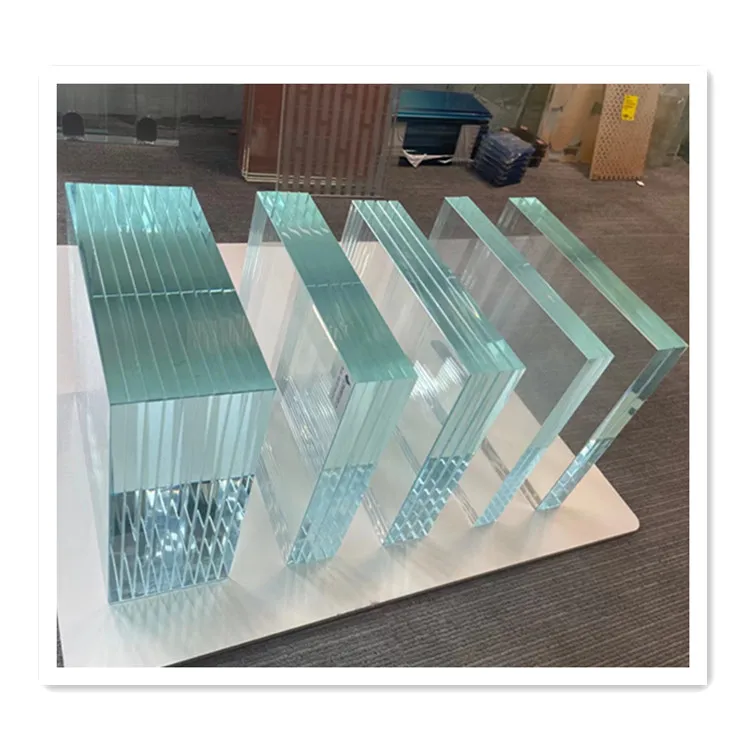

Factory glass sheet 0.55-1mm,1-19mm with wholesale price

Classification:

The original glass refers to a fixed-size glass produced by a flat glass factory. The size is usually based on some English conventional data, such as 12 feet (3660mm), 11 inches (3300mm), 8 feet (2440mm), 7 feet (2134mm), etc..The original glass refers to a fixed-size glass produced by a flat glass factory. The size is usually based on some English conventional data, such as 12 feet (3660mm), 11 inches (3300mm), 8 feet (2440mm), 7 feet (2134mm), etc. Wait. The size of glass required by customers is ever-changing, and it is impossible for glass factories to satisfy all of them. The purpose is to facilitate mass production, packing, and transportation.End users have various requirements for glass size. This kind of glass cannot be used directly and needs to be modified. Relative to the finished product board, this glass from the glass factory is called the original board or the original sheet.

History:

At the end of the 1950s, the British Pilkington Glass Company announced to the world that the float glass forming process of flat glass was successfully developed, which was a revolution to the original grooved top forming process. For a time, a stream of float heat converged into a "float madness" sweeping the world. Many countries in the world have spent huge sums to buy Pilkington patents, but Pilkington has imposed a technical blockade on China. The western technology blockade made us realize that the development and production of China's float glass must take the road of self-reliance and independent innovation. In May 1971, the former Ministry of National Building Materials Industry decided to carry out the float industry test in Luobo. Glass experts from all over the country gathered in Luobo, and more than a thousand employees of Luobo joined the battle.The production of float glass is a brand-new undertaking in China before. Since there is no information available for reference, there have been waves of problems from the beginning of experimental production. Without a designer, experts from the building materials department and the vast number of scientific and technical personnel from Luobo worked on the design in the boiler room, drawing sketches before construction. Without large-scale lathe equipment, Luo Bo's fitters used a small furnace craftsman to make pots and process a 25-meter small tin bath on site. At that time, an important problem encountered in the production process was that high-temperature glass water easily condensed when it passed through the tin bath, causing uneven glass thickness. Sometimes the glass of water splashed in the tin bath, and workers were injured everywhere. After long thinking, the technical staff of Luobo designed electric heating equipment on the top of the tin tank, and the problem that glass water easily condenses through the tin tank was solved. Then, they developed the glass edge-drawing machine by themselves, carefully designed the speed, angle, pressing depth, and modified the process shape of the molding part. The glass becomes wider and wider, and flatter, and the quality is getting higher and higher. On September 23, 1971, Luobo's vast number of cadres and workers, under the guidance of the ministry leaders and relevant experts, with the full cooperation of brother units, fought together for more than three months, and finally successfully built the first float The glass production line produced China's first float glass. The mechanical strength, flatness and light transmittance are better than other flat glass. With superhuman wisdom and hard work, Luo Bo fulfilled the Chinese float dream.

From 1971 to 1981, Luobo implemented a large-scale technical transformation on this line three times. The melting line of the production line reached 225 tons, the board width exceeded 2 meters, and the total yield reached 76.96%. At the beginning of 1979, a thinner 4 mm glass was produced stably. The technology and equipment of the "Luoyang Float Glass Process" have also been improved, and the technical level has been continuously improved.

From April 27th to 30th, 1981, the State Science and Technology Commission organized national glass experts and scholars and leaders of related departments to hold a national technical appraisal meeting for "Luoyang Float Glass Process" in Luobo. The third national technical appraisal meeting after the hydraulic press, the meeting officially named this process as China's "Luoyang Float Glass Process", and awarded the gold medal for creativity and invention. The birth of "Luoyang Float Glass Technology" in Luobo ended an old era, ushering in a new dawn of the development of China's glass industry, opening up a new era of reform, innovation and development of China's glass industry. The development has erected a majestic monument, becoming one of the world's three major float crafts in the world glass industry alongside the Pilkington float in England and the Pittsburgh float in the United States.

Advantages:

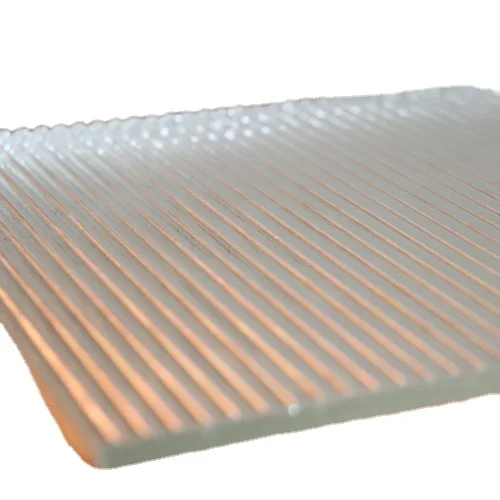

It comes out of the tin bath where the glass floats on the surface of the tin bath. Therefore, this glass is flat and free of water ripples.Used in mirror making and automobile glass. It's a big advantage that it doesn't show face or shape.The second is the ore quartz sand used in float glass, with good raw materials. The glass produced is pure and transparent. Bright and colorless. No glass goblets, air bubbles and the like.The third is that the structure is compact, heavy, and smooth to the touch. The same thickness per square meter is larger than the flat plate, which is easy to cut and not easy to break.More than 200 production lines across the country are produced in strict accordance with national standards. This glass is the best glass for civil buildings. Its price, compared to the same thickness, is only about 4 yuan per square meter higher than flat glass.

Technology:

The forming process of float glass production is completed in a tin bath with a protective gas (N2 and H2). Molten glass flows in continuously from the tank kiln and floats on the surface of the tin bath with relatively high density. Under the action of gravity and surface tension, the glass bath is spread, flattened on the surface of the tin bath, and the upper and lower surfaces are flat, hardened and cooled After being led to the transition roller table. The roller of the roller table rotates, pulls the glass ribbon out of the tin bath and enters the annealing kiln. After annealing and cutting, the float glass product is obtained. Compared with other molding methods, the float method has the following advantages: It is suitable for high-quality manufacturing of high-quality flat glass. If there is no corrugation, the thickness is uniform, the upper and lower surfaces are flat and parallel to each other. The scale of the production line is not limited by the molding method. Low consumption; High utilization rate of finished products; Easy scientific management and realization of full-line mechanization and automation, high labor productivity; Continuous operation cycle can be up to several years, which is conducive to stable production; It can provide suitable conditions for online production of some new varieties, such as Electro-float reflective glass, spray-coated glass during annealing, cold-end surface treatment, etc.Monolithic float glass has poor sound insulation performance, and its performance is based on GB / T8485—2002 “Classification and Detection of Air Sound Insulation Performance of Building Exterior Windows” and GBJ75—1984 “Specifications for Measurement of Sound Insulation in Buildings”, with reference to international standards Standards ISO140 and ISO717 identify the sound insulation performance index. The weighted sound insulation volume Rw is used to measure the sound insulation performance index, and its unit is DB; another sound insulation performance index STC can be used as a reference index.

Features:

For float glass, due to the better uniformity of thickness, the transparency of its products is also stronger, because after the tin surface treatment, it is relatively smooth. Under the action of surface tension, a relatively smooth and flat surface is formed. Better glass with stronger optical properties. This float glass has particularly good decorative characteristics. It also has good transparency, brightness, purity, and bright indoor light. It also has a wide field of view. With the best choice of materials for building windows and doors, and natural lighting, it is one of the most widely used building materials. It can be said that in terms of various types of building glass, this type of float glass is the most widely used for glass deep processing One of the most important original films. Ultra-white float glass mainly features the best transparency and purity.

Difference:

What is the difference between ordinary flat glass and float glass.

A: Both ordinary flat glass and float glass are flat glass. Only the production process and quality are different.Ordinary flat glass is transparent and colorless produced by using quartz sandstone powder, silica sand, potassium fossil, soda ash, mirabilite and other raw materials in a certain proportion. It is melted at a high temperature in a melting furnace and produced by the vertical pull-in method or the flat drawing method and the calendering method. plate glass. Ordinary flat glass is divided into three categories according to appearance quality: first-class product, first-class product, and qualified product. According to the nominal thickness, there are 12 specifications of 2, 3, 4, 5, 6, 8, 10, 12, 15, 19, 22, and 25mm. (See "Flat Glass" GB11614-2009)

B: Float glass is prepared from sea sand, quartz sandstone powder, soda ash, dolomite and other raw materials in a certain proportion. After melting at a high temperature in the melting furnace, the glass liquid flows continuously from the tank kiln to the metal surface and floats on the liquid surface. Transparent and colorless flat glass made of fire-polished glass ribbon with uniform and flat thickness, which is separated from the liquid metal after cooling and hardening, and then annealed and cut. The glass surface is particularly flat and smooth, the thickness is very uniform, and the optical distortion is small. According to appearance quality, float glass is divided into three categories: superior product, first-class product and qualified product. Divided into three types according to thickness: 3, 4, 5, 6, 8, 10, 12, 15, 19mm.

C: The quality level of the appearance of ordinary flat glass is judged based on the number of defects such as corrugations, bubbles, scratches, grit, sand, and lanes. The quality grade of the float glass appearance is judged based on the number of defects such as optical deformation, bubbles, inclusions, scratches, lines, and fog.

D: ordinary glass, emerald green, fragile, low transparency, easy to age and deform under rain.Float glass, transparent float glass is a glass paste that enters the tin bath through the control gate. After gravity floats on the surface of the molten tin due to gravity and its own surface tension, it enters the Xu cold bath to make both sides of the glass smooth and uniform, and the ripples disappear. production. Dark green, smooth surface without ripples, good perspective, and a certain toughness.

E: The production process of float glass is different from ordinary glass. The advantage is that the surface of the float glass is hard, smooth and flat. The color of the float glass is different from that of ordinary glass when viewed from the side. Of deformation.

Prospect:

The upgrading of the consumption structure of residents, the encouragement of independent innovation by enterprises, the construction of new rural areas and the process of urbanization will ensure that the medium- and long-term demand for glass products in the domestic market continues to grow. With the development of construction, automobile, decoration, furniture, information industry technology and other people's requirements for living space environment, functional processed products such as safety glass and energy-saving insulating glass have been widely used. The supply and demand pattern and consumption structure of flat glass are changing.

The development of the glass industry is associated with many industries in the national economy, and the glass industry plays an active role in promoting the development of the entire national economy. Therefore, the eleventh five-year plan also put forward specific requirements for the development of the glass industry. Various laws and regulations have also been promulgated to regulate the healthy development of the glass industry. Under the new situation, the glass industry must change the growth mode and effectively adjust the industrial structure in accordance with the requirements of the scientific development concept in order to promote the healthy development of the industry.

At present, the more mature float glass manufacturers in China are represented by Fujian's Fuyao Glass Group and Anhui Blue Glass Group.

Energy saving:

The glass industry is a high energy consumption industry. Glass melting furnaces are the most energy-consuming equipment for glass production lines. Fuel costs account for about 35% to 50% of glass costs. The unit consumption of most of the float glass melting furnaces designed by our country can reach 6500kJ / kg ~ 7500kJ / kg glass liquid. The large foreign float glass enterprises only have 5800kJ / kg glass liquid. We have a certain gap with the international advanced level.The thermal efficiency of glass melting furnaces in developed countries is generally 30% to 40%. The average thermal efficiency of glass melting furnaces in China is only 25% to 35%. The structural design and insulation measures of the furnace are unreasonable. The low quality of the refractory materials used is one of the important reasons for this gap. Secondly, the backward operation technology and inadequate management of domestic float glass process are also the reasons for high energy consumption, poor melting quality and short furnace life. Up to now, China has more than 140 float glass production lines, the glass production capacity has increased rapidly, and market competition has gradually heated up. As the heavy fuel of glass as the main fuel, prices continue to rise, and the proportion of glass costs is increasing. Therefore, reducing glass energy consumption is of great significance for reducing production costs, improving the market competitiveness of enterprises, reducing environmental pollution, and alleviating energy shortages.Energy conservation of glass enterprises is a long-term task. Technical personnel at home and abroad actively carry out research, such as optimizing the furnace structure design, oxygen-enriched combustion, oxy-fuel combustion assisted melting, and heavy oil emulsification technology. At present, many enterprises have begun to implement energy-saving measures in the production process, and explore energy-saving measures in aspects such as glass production process control.The moisture, temperature and fuel consumption of batch materials are well known, and the state of moisture in the batch is closely related to the temperature of the batch. When the batch temperature is higher than 35 ° C, most of the water adheres to the surface of the refractory sand particles in a free state, so that more soda ash can be adhered to enhance the fluxing effect. When the temperature of the batch is less than 35 ° C, the moisture in the batch will form Na2CO3 · 10H2O or Na2CO3 · 7H2O with soda ash, and Na2SO4 · 10H2O crystal water compound with thenardite, which will make the surface of the sand grains lose moisture and appear dry, which will weaken the fluxing effect.

Due to the low temperature in winter in northern areas, the batch temperature is generally lower than 35 ° C, and in some areas it is only about 20 ° C. In order to maintain the wet appearance of the batch, the method of increasing the moisture of the batch is usually adopted. Although it plays a certain role, it also brings more disadvantages, such as agglomeration of the silo wall and increased fuel consumption. Some people have calculated that the amount of oil consumed by the water entering the kiln is 0.085 kg oil / kg water.

Mildew proof:

Moldy glass has always been an industrial problem. Glassy mildew (that is, anti-alkali) has chemical reactions that change the surface properties of the glass. Rainbow, mold spots, watermarks, oil marks, paper grains and other phenomena appear on the surface under sunlight.

Moldy glass often occurs during production, storage and transportation. The moldy glass product surface will lose its luster, lose its transparency, appear rainbow, white spots or patches (not easy to separate), etc., which seriously affects the quality of float glass products, leading to The image of glass companies among downstream customers has been greatly reduced, which has further affected the price of finished products. Especially under the current slump in the glass sales market, an important measure for enterprises to maintain strong competition is to further improve the quality of glass, minimize the scrap rate of glass caused by mold, and reduce production costs.

Therefore, choosing a good anti-mold product is especially important. At present, the glass mold protection mainly includes three types: anti-mildew powder, anti-mildew paper, anti-mildew liquid. Among these three types of products, the mildew resistant powder is the best, which is a nano-scale polymer material, which has the characteristics of environmental protection, high efficiency, and easy cleaning. Among them, imported mildew-resistant powder has attracted much attention from glass companies for its high-quality materials and strict production requirements. However, its high price has made glass companies daunting and the cost has increased severely. In recent years, the rise of domestic anti-mildew powder is making up for this deficiency. The price only accounts for 1/3 of the imported powder, and some of the company's products have reached or even exceeded the international level in quality, which fully meets the production needs of domestic glass companies. As the added value of glass products is getting higher and higher, the use of anti-mildew products is getting more and more attention. In response to the development of glass facing the high-end glass market, a new generation of "coconut shell" mold-proof products has appeared, which greatly improves the effect of mold-proof isolation and cleaning of glass. Regarding mildew-proof mold, although it is easy to operate, has good mildew-proof effect, and can be recycled, it is gradually replaced by powder products due to its high use cost and prolonged storage time, which is prone to paper printing. However, the anti-mildew product is still not mature enough, the market usage rate is not high, and the time is too long, which may lead to cleaning and other characteristics.

Tin defect:

The function of the float glass tin bath is to melt the molten glass in the melting furnace under a certain temperature system through the external force of the main drive and the edger to form a glass with a certain width and thickness. Into the annealing kiln.

The tin bath in the float process uses a metal tin solution as a floating support medium, and a mixed gas of nitrogen and hydrogen as a protective gas. In the relatively closed environment of the tin bath, many complicated chemical reactions occur, and some products of these chemical reactions will bring many glass defects and affect the product quality.

The environmental and structural characteristics of the float glass tin bath determine that tin defects are inevitable and can only be effectively controlled in actual production, but not eliminated.

sizes:

L*W | difference | 2440*1830mm | 3660*2440mm |

Thickness | 0.55-2mm | 2-5mm | 5-19mm |

Visiting

Похожие товары

33 1 ламинированное закаленное стекло 55. 66 2 44 6 38 10 8 16 12 13 52 мм низкожелезный полированный край

Высококачественное свинцовое стекло с защитой от излучения всех размеров для

Различные высококачественные устойчивые к высоким температурам ультрабелые конденсаторные

4 мм 5 6 8 м 10 12 15 прозрачное полностью закаленное термостекло окно раздвижная дверь стеклянная настенная

Закаленное стекло с низким содержанием железа 8 мм 13 дюймов ультрапрозрачное кристаллическое закаленное vidrio ультрапрозрачный лист цена от

AS/NZS AGC Planibel G PG Low-e изолированные стеклянные блоки IGU с двойной тройной

Декоративное строительное стекло с ледяными цветами и золотым титановым покрытием зеркало для ванной

Новые поступления

Новинки товаров от производителей по оптовым ценам