Топ продаж Тип коробки в линии роторный дегазационный блок для алюминия

- Категория: Ceramics >>>

- Поставщик: Jinan Hydeb Thermal Tech Co. Ltd.

Сохранить в закладки 62534251668:

Описание и отзывы

Характеристики

High Efficient Launder Type In-line Rotary Degassing Unit for Purify Aluminum Liquid

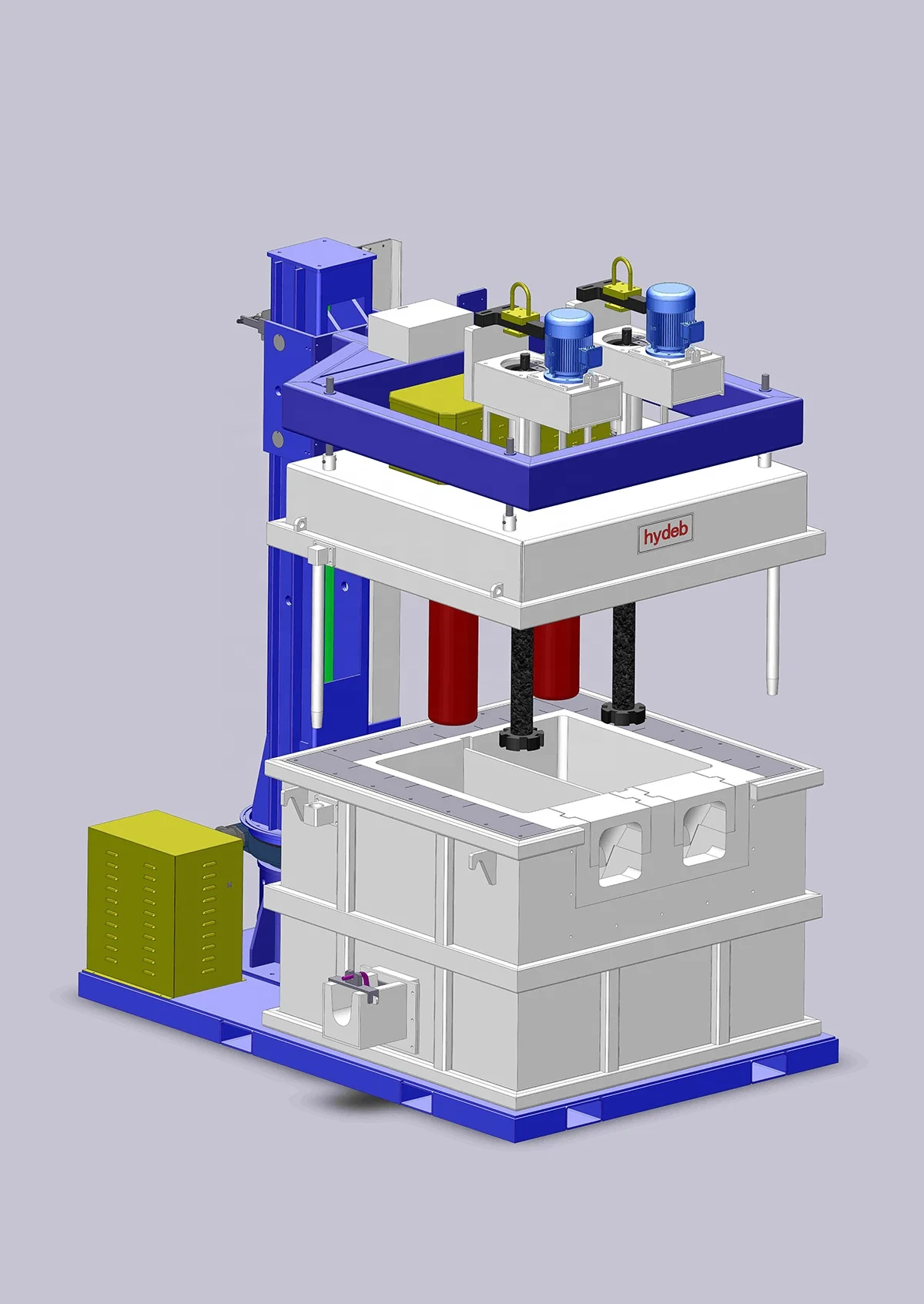

Box Type In-line Rotary Degassing Unit for molten aluminum

Box Type In-line Rotary Degassing Unit for molten aluminum

• Dehydrogenation/impurity removal/dealkalization

• One of the most effective molten aluminum degassing technologies, the first choice for high-end aluminum castings!

• The BDU Box type in-line rotor degassing unit is usually installed between the discharge outlet of the smelting furnace and the filter box. Melts flow into the BDU and rotate the rotor to break inert gases, forming a large quantity of dispersed bubbles, which then enter into the aluminum melts. After collision, capturing, surface adsorption and partial pressure action, the bubbles rise with gases and take hydrogen and oxide slags out of melts, making them into scums. Then, aluminum melts outflow from the degassing unit outlet, thus realizing the purpose of continuous in-line refining.

•BDU box-type in-line rotor degassing unit is designed based on the advantages of mainstream box-type degassing devices available in the market, with several key technologies, such as box sealing and anti-turbulence on the surface of aluminum liquid, improved ensuring high efficiency and continuous stability Low-cost operation.

Equipment Features

• Degassing efficiency is above 60%

- Optimized dispersion of process gases in melts;

- The maximum area and time of contact between dispersed bubbles and melts;

- The box is completely sealed, ensuring a stable inert gas environment;

- Smooth melt surface without turbulent effect.

• Easy installation and maintenance. Simple replacement of the liner of the preformed degassing box, which minimizing production downtime.

• Long component life, low maintenance and operation costs.

- The heater and heater protection tube have a service life of more than 3 months;

- The box has a service life of more than 1 year;

- The rotor and rotating shaft have a service life of more than 3 months;

- Gases can be cooled without the rotor rotating the main shaft.

• Solving the problem of large amount of aluminum in the box.

- A wholly tiltable degassing unit is optional. It can be tipped over at a specified time before the end of casting to pour all molten aluminum stored in the box into the launder to finish casting, thus solving the problem of excess aluminum storage in the box.

Items | Parameters |

Maximum temperature of molten aluminum | 750℃ |

Precision of molten aluminum temperature control (static) | ±2℃ |

Melt heating ability | ≥20℃/h |

Launder surface temperature rise | ≤40℃ |

Launder lining life | ≥12 months |

Continuous service life of heater | ≥3 months |

Heater protection tube | ≥4 months |

Continuous service life of rotor | ≥3 months |

Rotor speed (stepless speed regulation) | 100-500rpm |

Refined gas | High-purity Ar or high-purity N2: pressure 0.2-0.5 MPa, purity ≥99.996%, Water (ppm) ≤3, Oxygen (ppm) ≤5 |

Degassing efficiency |

When it is not greater than the maximum flow rate, the inlet hydrogen content is ≤0.30ml / 100gAl, when the aluminum liquid is 700-740 ℃, the hydrogen content after degassing is ≤0.12ml / 100g -Degassing efficiency≥60% when hydrogen content at the inlet>0.30ml/100g-Al. |

Dealkalization effect | Each alkali metal content<10ppm before refining, each alkali metal (Na, Li, Ca) content <2ppm after refining |

Power supply | Power Supply: 380V AC 50Hz, ≤60kw |

Notes: Mixed gases, such as chlorine and argon, can be added as the case may be.

The degassing effect refers to 3xxx alloy.

Specifications Items | Number of Rotors | Maximum Molten Aluminum Flow t/hr | Maximum Gas Consumption L/min | Heating Power kw | Number of Heaters |

BDU-15 | 1 | 15 | 90 |

| 1 |

BDU-30 | 2 | 30 | 140 |

| 2 |

BDU-50 | 2 | 50 | 160 |

| 2 |

BDU-70 | 3 | 70 | 180 |

| 3 |

Notes: Customizable according to customer needs

1. Three-chamber/four-chamber degasser

2. Optional degassing box tilting function, and whole degassing box

tilting function (including the external flow slot).

Похожие товары

Высокое качество низкие температуры сухого шестиугольная стекло из пористой керамики для печати

Шарик из нитрида кремния для автомобильного двигателя экспортного класса 2 969 мм 3 7

Высокочастотное устройство Керамика/керамика из стеатита/высоковольтная электронная

Овальные керамические плитки 11*15

Циркониевая керамическая катушка/керамическая трубка ZrO2/промышленная керамика продается непосредственно

Алюминиевая тигельная кастрюля для DSC STA DTA TGA Термическое

Silex подкладка блоки установлены в мяч стана

Новые поступления

Новинки товаров от производителей по оптовым ценам