0.8TPH Заводская распродажа 1200 мельница для мокрого помола процесс измельчения

- Категория: >>>

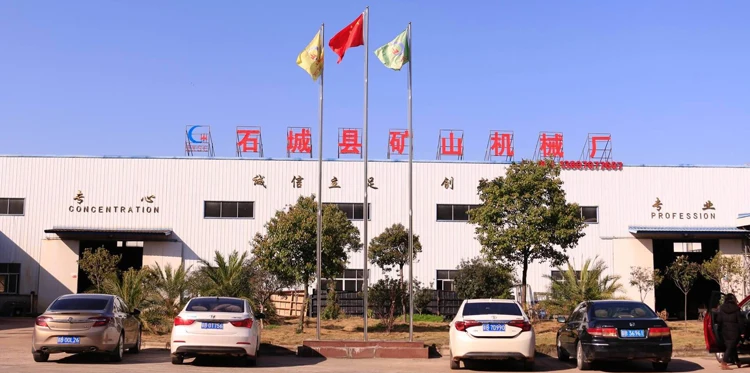

- Поставщик: Jiangxi Province County Mining Machinery Factory

Сохранить в закладки 62545555957:

Описание и отзывы

Характеристики

As their small investment, high yield, the production cost is low, good benefits, praised by users, domestic alternative to theball mill equipment. Grind gold machine easy installation and maintenance, small investment, high yield, quick, low-cost

production, is the ideal equipment for mine SMEs beneficiation.

rolling repeatedly reach moisture equilibrium ratio of uniform, low gas content, improve the forming rate and forming quality, grind the material through the machine molding Products with high density, good strength, no porosity ratio weight. Energy efficient, high volume of output, the product is used for iron ore process tailings recovery, not to slag the loss of effective resources can be fully utilized.

1.The normal operation of the mill, before they start feeding.

2, this machine prohibit strip start, the outage at boot time, you must first clean up the residual ore in the middle of the

milled slot and then start.

3, should be uniform feeding not erratic, it is best to use the feeder.

4, bearing frequent butter, gear box or car rear axle with frequent checks whether the loss of gear oil.

5, regular checks of the various parts of the screw is loose.

6.Found bearing damage must be promptly replaced, shaft eccentric avoid damage to other parts

7 mill runtime to pay attention to that the reducer or bearing part of the presence or absence of abnormal sound, whether the temperature is too high, the motor current is too large irregularities; should be shut down immediately if the

Model | Specifications | Input size | Rotate speed | Capacity | Power | Machine weight |

1600A | 1600×400/2100×500*180±20mm | <30mm | 18-20 | 5-6T/H | 37KW | 16.3 |

1500A | 1500×400/2100×500*180±20mm | <30mm | 18-22 | 4-5T/H | 30KW | 13.5 |

1500B | 1500×350/2050×450*150±20mm | <30mm | 18-22 | 4-5T/H | 22KW | 12.3 |

1500C | 1500×300/2050×400*150±20mm | <30mm | 18-22 | 4-4.5T/H | 22KW | 11.3 |

1400B | 1400×250/2050×350*150±20mm | <30mm | 18-22 | 3-4T/H | 15kw | 8.5 |

1400A | 1400×300/2050×400×150±20mm | <30mm | 18-21 | 3-4T/H | 18.5kw | 9.6 |

1300B | 1300×250/2000×350×150±20mm | <30mm | 18-22 | 2.5-3.5T/H | 11kw | 7.5 |

900A | 900×170/1700×220×45±10mm | <30mm | 11-13 | 0.1-0.5T/H | 3kw | 2.9 |

900B | 900×140/1700×170×45±10mm | <30mm | 11-13 | 0.1-0.5T/H | 3kw | 2.6 |

1200A | 1200×200/1800×250×100±10mm | <30mm | 11-19 | 2-3T/H | 7.5kw | 5.5 |

1200B | 1200×180/1800×250×100±10mm | <30mm | 11-19 | 2-3T/H | 5.5kw | 5.5 |

1100A | 1100×200/1800×250×100±10mm | <30mm | 11-19 | 1-2T/H | 7.5kw | 5 |

1100B | 1100×180/1800×250×80±10mm | <30mm | 11-19 | 1-2T/H | 5.5kw | 5 |

1000 | 1000×200/1800×250×80±10mm | <30mm | 11-19 | 0.5-1T/H | 5.5kw | 4.5 |

Mineral:rock gold

Model:JXSC 1600

Feeding size:10mm

Output size:0.02mm

Power:37KW

Time :2017 year

machines:shaking table,wet pan mill ,pumps ,belt conveyor ,etc

Capacity:5TPH

Mineral:rock gold

Model:JXSC 1600

Feeding size:20mm

Output size:0.1mm

Power:37KW

Time :2018year

machines:feeder,magnetic separator,shaking table,wet pan mill ,pumps ,belt conveyor ,etc

2. Wet pan mill are fixed and loaded in container directly.

2. Wet pan mill can be also shipped by air if customers request.

Our Core Advantages as below :

1.+30 years history FACTORY at mining machinery

2.Provide engineer team after sales service

3.Provide Complete set mineral processing plant

4.Provide Sample testing service in factory lab for free

5.Provide professional Mining Solution Consulting

1.How is the quality of your products? (mining equipment/mining machine)

Answer: Our products are manufactured strictly according to national and international standard, and we will take a test on every grinder before delivery.

2.Guaranteed:

Answer: All of our products are guaranteed for one year. If products quality is not consistent with the description as we described or the promise before you place order, we promise 100% refund.

3.How about price?

Answer: For the complete same machine, we can promise our quality is the best when the price same as other competitors, and our price can be lowest when the quality at standard level.

4.Service and Payment Terms?

Answer: We can accept T/T and L/C; 30% deposit, 70% balance before delivery, which is international trade practice; Finished product pictures will provide to customers before delivery.

Our service

Pre-sales service: We provide you with the prophase plan, process flow design and manufacturer equipment according to your special demand.

Sales service: Send technicians to the jobsite guiding the installation and adjustment, training operators and finishing the check and accept together with you.

After-sales service: To establish long term friendship, we will reg-ularly pay return visit to customers. Supplying technique,

building design, instruction, installation and debugging for free.

Lifelong service: One year warranty to make sure your machine runs constantly.Always offer lifelong service and provide spare parts for a long term.

Very good service help us win many clients from all over the world.

Похожие товары

Послепродажный высококачественный вилочный погрузчик 3T, тормозные колодки из асбестового материала

ПТФЭ кран в форме груши сепараторная Воронка с градиентом

Классический Светодиодный Потолочный настенный светильник

Подносы для вечеринок с подсветкой, пластиковый барный стул с питанием от батарейки для шампанского, со светодиодной подсветкой, охладитель для льда и вина

Новый детский самокат, мигающий светильник, для детей 1-3-6 лет, детское широкое колесо, одноногий скользкий автомобиль, детский колесный самокат

Фондовая новые электронные компоненты память Xilinx Virtex-7 XC7VX415T-2FFG1157C

Выделите Автомобиль Стайлинг автомобиля СИД T10 194 W5W Canbus 6 SMD 5730 Светодиодные лампы Авто СИД зазор Свет T10 СИД автомобиль боковой лампы

Новые поступления

Новинки товаров от производителей по оптовым ценам