Автоматическая машина для резки бумаги

- Категория: >>>

- Поставщик: Wenzhou Longhua Machinery Co. Ltd.

Сохранить в закладки 62562890686:

Описание и отзывы

Характеристики

Scan the QR Code on the left

Scan the code on the left to see the working video of 1050ES Pharmaceutical Box Die Cutting Machine

Subscribe to our youtube channel to be informed with the latest advanced die cutting and creasing technology

1050E Automatic Kiss Cut Die Cutting Machine

1. The automatic kiss cut die cutting machine is specially used for the die cutting, creasing,

stripping labels

2. It is also used in a wide variety of sectors from packaging, label, and display manufacture

to commercial printing.

Die Cutting Samples of Kiss Cut Die Cutting Machine

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine.

Brief Introduction:

Machine Usage: Die cutting and creasing materials like Paper /Cardboard / PVC /Corrugated.

Die Cutting and Creasing Method: Flat Bed / Sheet Feed / Platen

Die Cutting and Creasing Speed: Up to 7500 sheets/mins

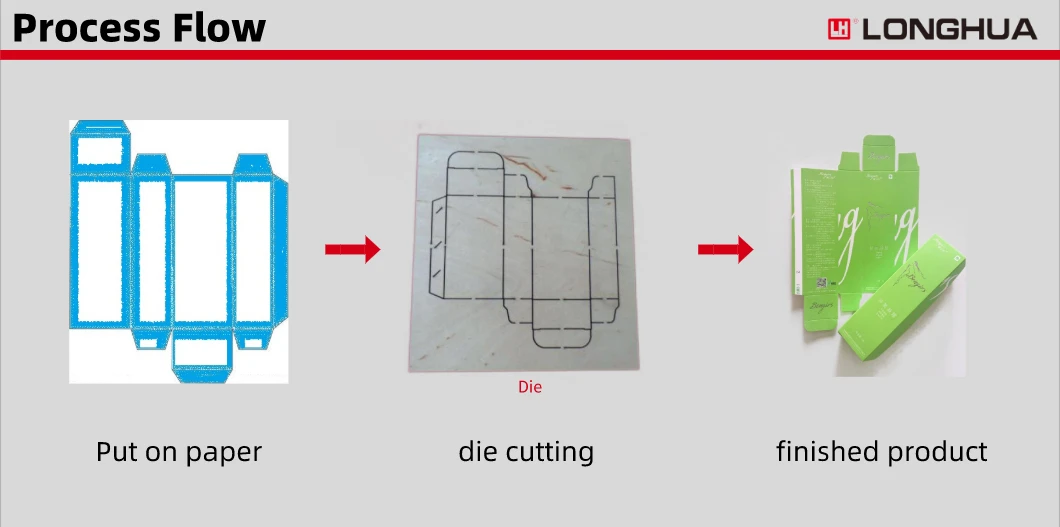

Die Cutting and Creassing Process Feed paper (round or rectange) sheet--> Paper Transfer --> Die Cut and crease

by press--> Transfer by gripper--> Finished products

Process Advantage of By combining highly accurate registration with precise sheet control at flat bed die cutting each stage of the process, a flat bed die-cutter offers the ultimate in quality when cutting, creasing or embossing sheeted material.

Die Cutting Samples

Apply creasing, die cutting, embossing, stripping on paper, cardboard, corrugated board and plastics etc, like boxes, folding boxes, labels, leaflets, book covers, hanging tags and greeting cards etc.

Machine Video

Machine Structure

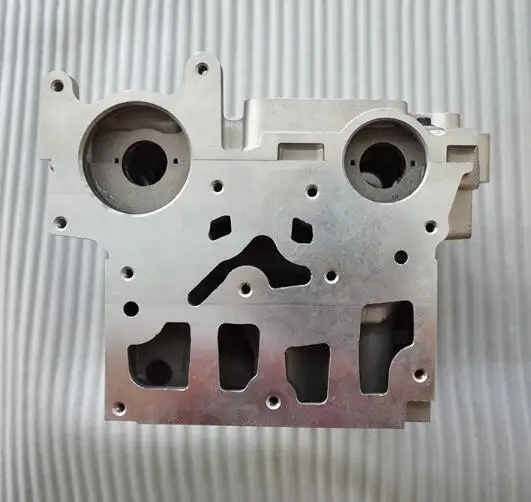

Machine Frame

☆ Full Machine Wall (rather platen parts only) is casting of Ductile Cast Iron 600# to ensure the machine shape (the head and back) won't change through times.

* The precision will be affected if the shape of

machine changed

Thick Machine Wall

Thick machine wall ensure the machine structure won't get crashed by high die cutting pressure.

All pressure parts are optimized design by finite element.

Machine Parts

Sheet Feed Section

Sheet Feed

1) Standard non-stop configuration and pre load unit.

2) Central

3) Double Sheet Detector

Feeder

☆ The whole set of feeder unit is imported from Taiwan (rather OEM and assembled), quality assured.

1) High precision feeder is adjusted with 4 lifting suction cups and 4 carrier suction cups

2) The suction angle and height can be adjusted according to the deformation of paper

3) The self-invented air blow device ensure the paper

Paper Transfer Section

Side Lays / Feed Table

1) Integrated push and pull of side lays which realize

the fast conversion of side lay.

2) The front registering unit can be fine adjustment and

with photo detector to detect double sheet during

transportation

3) Feeding belts with adjusting mechanism can modifying timing to the front position.

4) With foreign body resistance function.

Die Cutting and Creasing Parts

Die Cutting Chase

1) Pneumatic lock system on die cutting chase to increase efficiency

2) Micro-adjustment of cutting pressure controlled by

touch screen.

3) Cutting chase turn-over device to actualise short set up of repeat jobs (Optional)

4) Adopt 12-zone electric heating system with

independent controls

Paper Collection Parts

Paper Collection

1) Automatic conveyor at delivery equipped

2) Non-stop feeder with motorized side shift and non-

stop delivery with counter and tape inserter to ensure

continuous productivity.

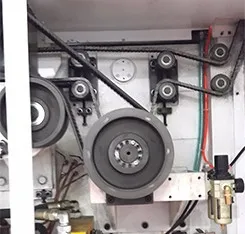

☆ Intermittent Transmission Mechanism of High Precision

Driving System

1) Use high configuration of driving system enusre the precision of die cutting and creasing.

Indexing driving - TAN TSU - Taiwan

Chain - RENOLD - German

Gripper Bar - JASU - Taiwan

Prenumatic Clutch - Itally - OMPI

* A high configuration of driving system is very important for those factory who have high demand on die cutting and

creasing, especially for foil stamping industry.

As this machine can finish the whole feeding, die cutting and creassing, collecting process in one pass, any error

that happens in any process during the die cutting will lead to the lack of the precision

Thus intermittent transmission mechanism and feeder of high precision are very important for an automatic die

cutting and creasing machine

Prenumatic Clutch

Gripper Bar

Indexing driving

Stripping Function

Check our 1050ES Model with stripping functions.

Click the image on the right to see the 1050ES model.

Chase Turn over device

Optional

1) Easy for operator to change the plate, save time and

increase efficiency.

2) The chase turn over device is more

professional by helping the operator during plate

changing.

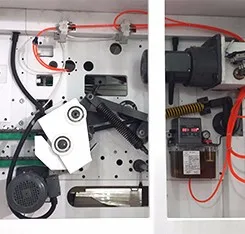

Electrical Equipments

Die Cutting / Honeycomb Chase

Other Machine Parts and Accessories.

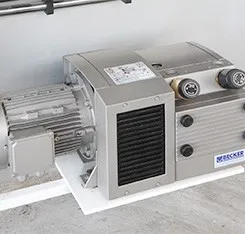

Air Pump

Touch Screen

Stripping Function

Triple action movement with upper, middle and lower stripping frame.Stripping pins or male / female die are available for different stripping jobs.

Centreline registration for Accurate positioning which can increase production efficiency.

Check more of our advanced machines details by email or IM chatting.

Skype: hollywang1287

Whatsapp: +86 18815016561

Mob/wechat: +86-18815016561

If you have any questions about our 1050 series automatic die cutting and creasing machine, please do not hesitate to contact us.

Похожие товары

Экономически эффективным Хлорированный диоксид титана TR-700 для электрофоретической краски

Портативный небулайзер для астмы Feellife, новая модель Air plus 3

Высококачественный центральный болт с шестигранной гайкой 10,9 oem 1513561400 для грузовика ISUZU

Высокое качество Свежие Мандарины апельсины фрукты для крупных партий товаров

Веб-камера с микрофоном и зажимом для онлайн-конференций

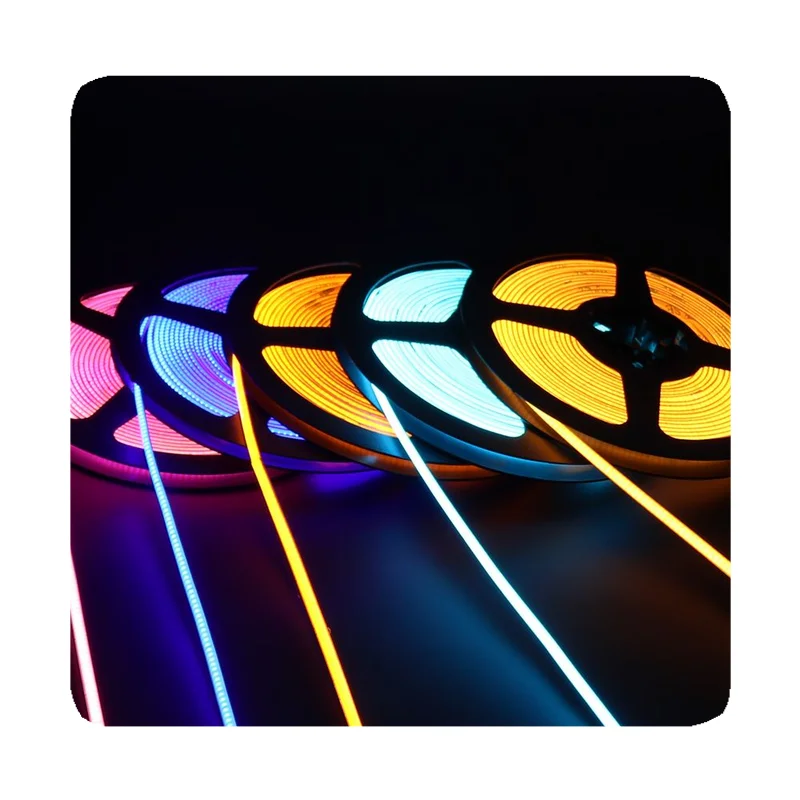

Новый 840 светодиодов DC24V DC12V COB RGB Светодиодная лента для украшения стен комнаты гибкая лента RGB лента подсветка телевизора геймер 20

Перекрестная хлопушка

Новые поступления

Новинки товаров от производителей по оптовым ценам