Стабильное производство древесных материалов биомасса сжигание гранул завод по производству

- Категория: >>>

- Поставщик: Jiangsu Liangyou Zhengda Co. Ltd.

Сохранить в закладки 62573613922:

Описание и отзывы

Характеристики

Stable production leftover wood material biomass burning pellets manufacturing plant

What material can be produced by biomass pelletizer?

Nearly all forestry and agro waste material can be made into wood pellets by our ring die wood pellet mill, such as: Wood Chips, Shaving, Sawdust, Groundnut shell, Sugarcane Bio gases, Caster Shells/Stalk, Coffee Husk, Paddy Straw, Sunflower Stalk, Cotton Stalks, Tobacco Waste, Mustard Stalk, Jute Waste, Bamboo Dust, Tea Waste, Wheat Straw, Palm husk, Soybeans Husk, Coir Pitch Barks/Straws, Rice Husks etc. The final pellets can be used for industrial boilers and large power plants as well as home heating.

Definition of leftover material pellet production line

Take the leftover material from furniture factory or wood processing factory as raw material to solidified and extruded into high density biomass pellet through pretreatment and process. Biomass pellets does not contain sulfur or phosphorus. When it burns, it does not produce sulfur dioxide and phosphorus pentoxide and will not cause acid rain, does not pollute the atmosphere and the environment. As a new type of particle fuel has won wide recognition. Compared with the traditional fuel, it not only has the economic advantage but also has the environmental protection benefit, fully conforms to the sustainable development request.

raw material

Leftover material mainly from furniture factory, wood processing factory, wooden door manufacturer.

Process introduction

Make the leftover material into wood chips with 20-30mm dimension and 3mm thickness by chipping machine, then fine grinded into sawdust with 3-4mm by hammer mill, finally go to the pellet mill to make pellets, the final pellet diameter are optional from 6-10mm. After pelleting and cooling, it will be packed into 20-50kg/ bag by small bag packing scale for convenient transportation and sale. This Leftover material pellet production project can produce biomass pellet 3tons per hour and has a total power of 475kw, the area of workshop is about 1000m3 including the raw material warehouse and finished products warehouse, the whole line is characterized by compact design and reasonable structure, and satisfied by environment protection requirements, meanwhile it can be directed to customers design.

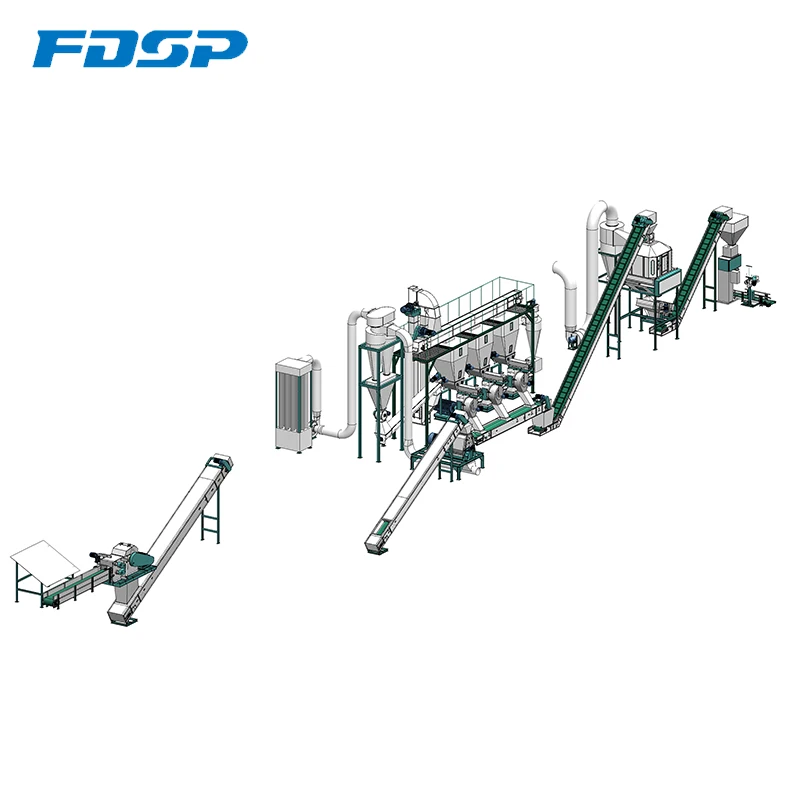

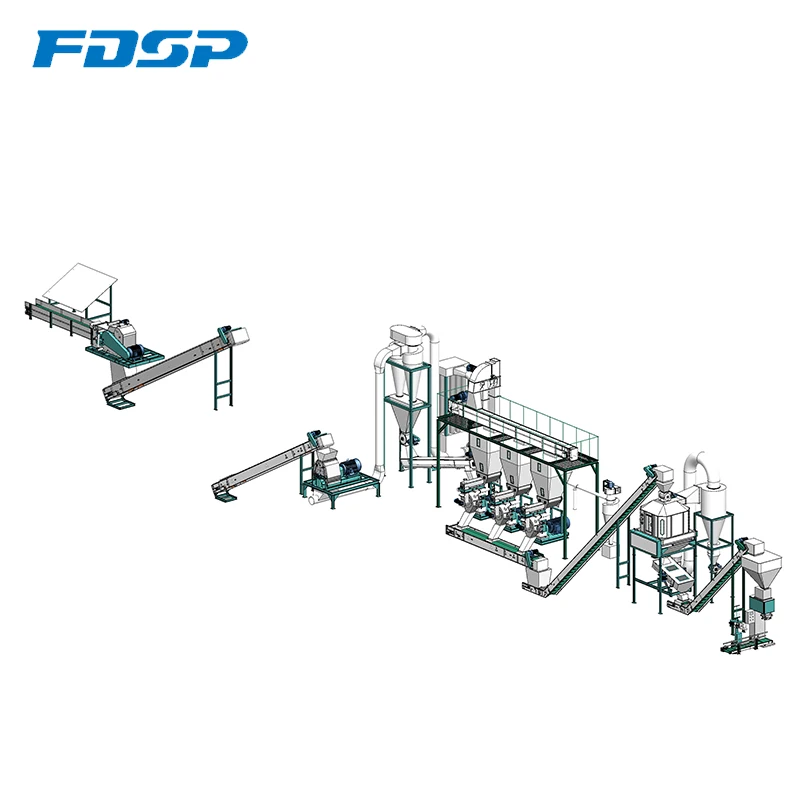

Technological process chart:

Process chart of leftover material pellet production project

Chipping process--Grinding Process--Pelleting Process--Cooling and packing process

The process is as follows

Chipping process

In the chipping process of leftover material pellet production project, leftover material are chipped into wood chips with 20-30mm dimension and 3mm thickness then go to following process. The feeding system of chipper consists of feeding part and press part, automatic control hydraulic system are adopt in press part, the material going smoothly in feeding system, material could be returned when overloaded to prevent blockage.

Chipper: LYGX216,main power 55kw,feeding roller power 3kw, oil pump power 0.55kw, capacity 10m3/h

Grinding process

The grinding process of leftover material pellet production project consists of more than one auxiliary equipment such as cyclone, bag filter, and the grinding work has no dust discharge. After grinding, the sawdust will be transported through pneumatic transmission by the fan suction air pressure. The output sawdust is generally about 3-4 mm. The hammer mill is a water droplet type structure with high grinding efficiency; the hammer mill rotor can be operated in forward and reverse directions to improve the service life of the hammer blade; the direct transmission mode of the motor is adopted, the transmission efficiency is high, and the maintenance is convenient.

Hammer mill: MFSP68*80,power 90kw,capacity: 3-4T/H

Pelleting process

Three set MZLH420 biomass pellet mill were designed in the pelleting process. The diameter of biomass pellet is optional from 6-10mm, and the biomass pellets have the characteristics of high calorific value, no pollution and low ash content, which can be widely used in biomass power plants, biomass steam boilers, household fireplaces, drying furnaces and biomass gasifier. The overleft material pellet production project has obvious advantages in the pelletizing process: the pellet mill is equipped with a forced feeder to force feeding into the ring molding chamber, which can make the pellet mill run smoothly, do not block the materials, and produce efficiently. Specially design of broken screw feeding, so that the poor flow raw materials smoothly feeding.

Pellet mill: MZLH420, main motor power: 90kw, power of forced feeder: 0.75kw, design with 1T/H output , quantity: 3sets

Cooling and packing process

In this cooling process of leftover material pellet production project, a cooler is used to reduce pellets temperature and decrease pellets moisture, low energy consumption, easy operation, high automatic degree, through the cooler cooling, pellets temperature is not higher than ambient temperature 5 ℃, after cooling the pellets moisture around 8-10%, particle density 650-750kg/m³.

According to the customer's local sales needs, the appropriate packing scale is selected for customer to sell products more easily. There are usually two specifications: small bag and ton bag. 20-50kg/bag for small bags, 500-1000kg/bag for ton bags. The packing scale has high automation degree, high packing accuracy, and The measurement by sensor in the weighing system is with high sensitivity and strong anti-interference ability.

Cooling equipment: SKLB2.5, cooling volume : 2.5m3 design with 3-4t/h output.

Packing scale: SDBLY-K,bag size20-50kg/bag,packing speed: 3-5bag/min

Detail quotation solutions for you, we need to know information as follows:

(1). What capacity would your prefer?

-----The Capacity Range of Wood Pellet Machine: 0.8-1T; 1.5-2T; 2-3T; 3-4T.

(2). What is your raw material?

-----According to different raw material(such as hard wood, soft wood, straw, rice hust), capacity is different.

(3). What is your raw material size?

-----Best size for pressing high quality pellets is 3mm-5mm.

(4). What is the moisture of your raw material?

-----Better to be 10-15%. ( If large than this, then we will recommend your Dryer Machine)

(5). Final Pellets Size?

-----We have Diameter for Pellets: 6mm, 8mm, 10mm, 12mm(Different Diameters for your Different Requirement.)

------Pellets Length: Adjustable20-50mm. (Normally our clients ask pellets length of 33mm,between 30-36mm)

Our factory:

Our honours:

Packing and delivery:

Похожие товары

Всемирно известный автогрейдер Sinomach PY200MH по низкой цене

23340 NSK NTN Koyo сферический роликовый подшипник 23340

Хорошее качество, портативная перезаряжаемая через USB бритва, бритва для бороды, для мужчин

Лидер продаж, Корейская импортная машина для выпечки риса для малого бизнеса

SHANTUI 22t Гидравлический Вибрационный дорожный уплотнитель SR22M-C5

Входной шланг/Входная труба 1,5 м ПВХ дренажный шланг для стиральной машины оптом

Высокоэффективная машина для гранулирования на Филиппинах, машина для гранулирования на Филиппинах

Новые поступления

Новинки товаров от производителей по оптовым ценам