Фторполимерный порошок ETFE смола для электростатического распылительного

- Категория: Plastic Raw Materials >>>

- Поставщик: Beijing Starget Chemicals Co. Ltd.

Сохранить в закладки 62585779870:

Описание и отзывы

Характеристики

Product Description

ETFE

Technical Index

Properties | Item | Unit | Test Method/ Standards | Static powder coating DH-4051 |

Physical properties | Apparent density | g/ml | ISO60:2000 | ≥0.6 |

Average particle size | um | Laser diffraction | 40-70 | |

Melting point | ℃ | DSC | 250±10 | |

MFR | g/10min | ASTM D1238 (297℃*49N) | 10-25 | |

Specific gravity | g/ml | ASTM D792 | 1.70-1.76 | |

Hardness Durometer | Shore D | GB/T2411 | 60 | |

Mechanical properties | Tensile strength at break | Mpa | ASTM D638 | ≥30 |

% | ASTM D638 | ≥300 |

Benefits of ETFE coating

* High film-build capabilities

* Industry-leading chemical resistance

* Very good dielectric strength

* Interchangeable and compatible liquid and powder topcoats

* A wide range of FDA-compliant options for food application

* Improved efficiency when the powder primer is used in conjunction with a complete powder system

* Compatibility with aluminum, stainless steel, and carbon steel substrates

* In-use operating temperature of 149 °C (300 °F)

Application

Corrosion proof for severe conditions reactor, tank, line, pump etc.

Precations

When dealing with ETFE powder for deep processing, operators must wear protective cloth and mask to avoid potential safety hazards, such as inhalation of dust and toxic gas, or hurt by high temperature. No open flame and smoking in workplace. Exhaust devices should be installed.

Packing & Delivery

The product should be stored in cool ventilated place and away from fire source and heat source. It should also be prevented against moisture and sunshine, kept in upright position and handled with great care.

Once opened, unused product should be repacked to avoid any dust or contamination.

STARGET Introduction

STARGET Exhibition

Contact

Похожие товары

Китай p450 паста ПВХ смола по Заводской Цене P440 51

Поликарбонатные гранулы средней вязкости по заводской цене поликарбонатные

Прозрачный наполнитель сумки для покупок цветной

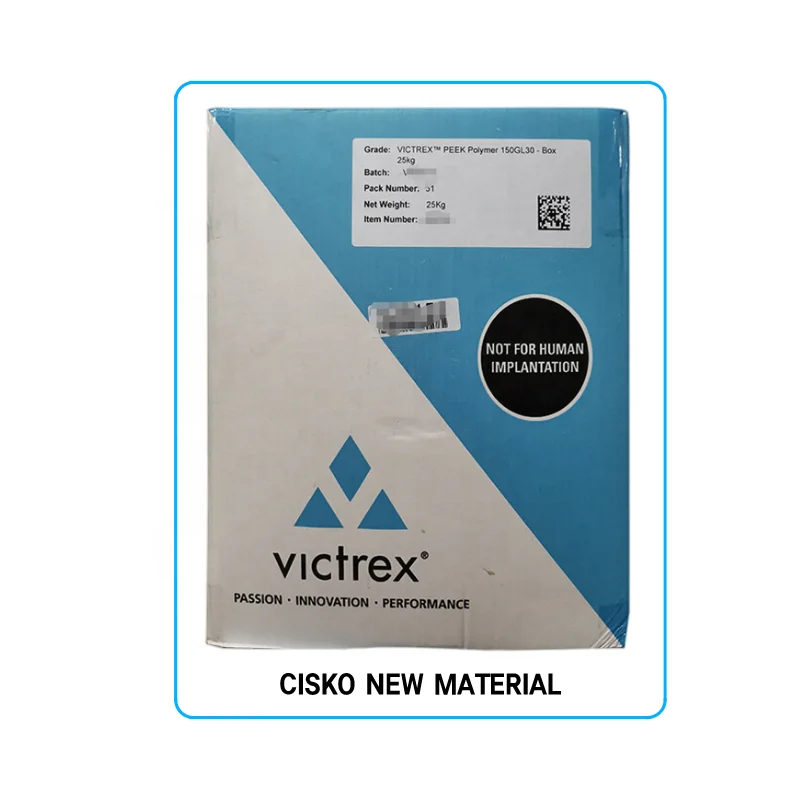

Victrex PEEK 450 г

Оптовая продажа поставка с завода пластиковые гранулы из натурального кристалла

Пластификатор ПВХ DPHP Di-(2-пропил гептил) фталат CAS

Clarifying masterbatch

Новые поступления

Новинки товаров от производителей по оптовым ценам