Specialized Producing for European Market Tools Lathe

- Категория: >>>

- Поставщик: Zhuzhou Sant Cutting Tools Co. Ltd.Zhuzhou Ltd.

Сохранить в закладки 704185407:

Описание и отзывы

Характеристики

Specialized producing for lathe

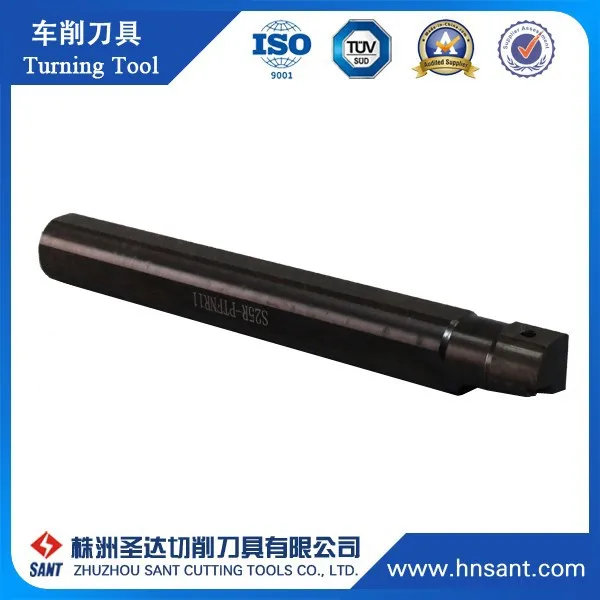

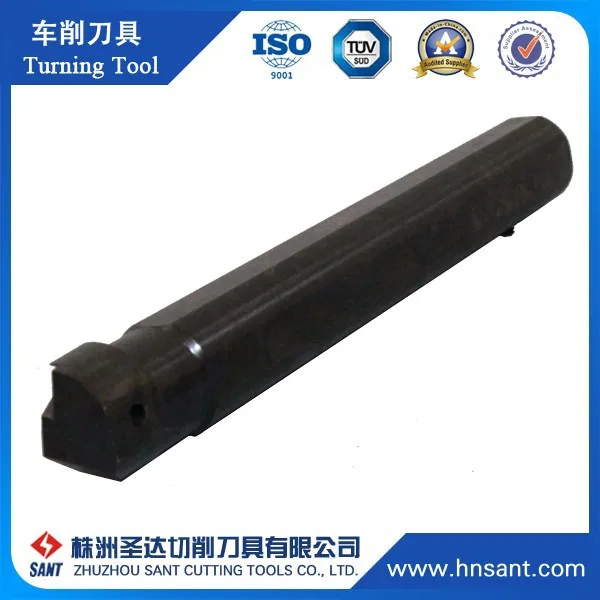

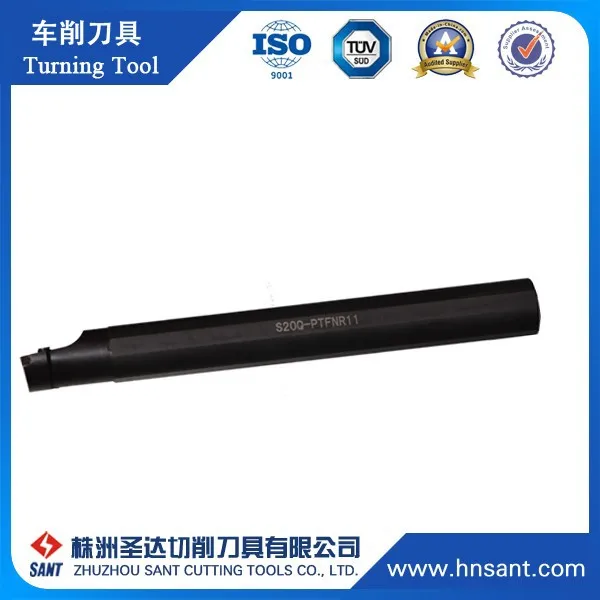

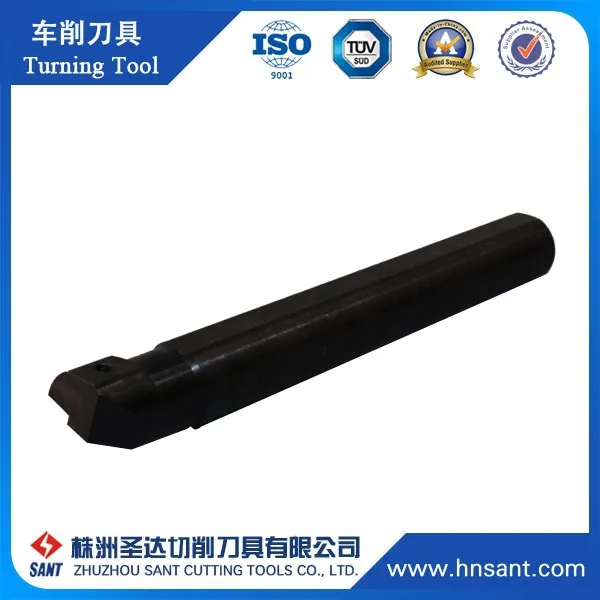

china internal turning tools(P type) description:

1: Can be used on cnc lathe machine and engine lathe .

2: Matched with CNC inserts with hole .

3:Spare part made of high quality steel , the hardness of screw is grade 12.9

4:Material 42CrMo and whole forging processing make the turning tool with long service life, better wear-resistantce,strength and rigidity,high working efficiency.

5:Using 0.01mm feeler gauge to insure the tightly connection between the inserts and the tool .

6:Cooperate with NIHONG-TECHNO ,adopt advanced heat treatment equipment, make sure the uniformity of the hardness(HRC40-47)

7: Processed with high precision CNC machining centre.

china internal turning tools(P type) Parameter:

Applicable Machine | CNC Lathe Machine |

Stock

| For standard, enough stock |

For non-standard , need to be customized | |

Non-standard order | Customize as request |

Laser Marking | Can print logo and model number as request |

Suitable for steel, cast iron, non-ferrous metal cutting | |

china internal turning tools(P type) picture show:

china internal turning tools(P type) packing:

transparent plastic bag for inner package;

blue plastic/corrugated box for outer package;

carton package for transportation.

can be customized as request.

china internal turning tools(P type) shipping:

| Port | Changsha/Shanghai/Guangzhou/Shenzhen/Hongkong | |

| Shipping | By Air ,By Sea or By Express | |

| Shipping Time | 4-10days By Express | Different Area many take different shipping days |

| 7-15days By Air | ||

| 25-55days By Sea | ||

| Trade Terms | FOB, CIF, EXW, CFR, DDU... | |

Pre-sale Service:

We have professional sales staff, who can get to know the details about your needs and offer feedback.

Sales Service:

After the signing of the contract, our professional sales staff will communicate and work on the production schedules or your change of demand.

After-sale Service:

We will arrange the returning and changing of the products timely if they have quality problems. At the same time, return visits will be made regularly to know service condition of our products.

Zhuzhou Sant Cutting Tools Co., Ltd. with years of experience in manufacture CNC Turning Tools , Milling Tools , Threading Toolholder, Boring Bar, Drilling Tools , Parting And Grooving Toolholder , Spring Collect etc.

Located in Zhuzhou—Chinese leading industrial for cemented carbide products. We have strong design team and passed the ISO9001 Certification. Also, we have various kinds of processing equipment, including MAZAK Five- Axis Linkage High-Precision Machining Center. All can meet your requirements!

Warmly Welcome you to have a visit of our factory .

Q 1: Do you offer inserts?

A:Yes, we can provide inserts, also we can supply inserts from korloy, ZCCCT and other brand.

Q 2: Is the whole working procedure finished by your workshop?

A: No, machining, assembling, testing, laser marking etc are all finished by our factory, heat treatment and surface treatment are finished by our cooperation company.

Q 3: How about your stock ?

A:We have about 50000pcs turning tools, 10000pcs milling tools, 10000pcs drilling tools in stock.

Q 4: What is your delivery time ?

A:It depends on your order. Normally 1-3days for stock, 10-25days for standard, 30-60 days for customized.

Q 5: How about the shipping time ?

A:Usually it will take 4-10days for Express, 7-15days for Air, 25-55 days for Sea, it also depends on the destination area.

Q 6: How do you guarantee your quality ?

A:Firstly, we do quality test during every process. And we use production instruction cards, when one process finished, the work will be signed on the production instruction cards.Secondly, we will collect all comments on our products from customers in time. And try our best to improving quality all the time.

Похожие товары

Производитель Wintool SOMT070306-AP Cnc Вольфрамовая Концевая фреза карбидная вставка для фрезерного инструмента

CNC Lathe Turning Carbide TNMG160404R/L-SIndexable Tungsten Inserts

OEM Polyurethane Cutting Tools Seal Ring Grooving Inserts for O Making Machine Tungsten Carbide

Colorful CNC Thread Inserts 16ER 16IR 1.0ISO 1.5ISO 2.0ISO 3.0ISO Internal and External Threads Hardened Steel

Карбидный вольфрамовый инструмент TGF32R TGF32L TGF32 TGF 32 R L 100 120 150 200 300 токарный

Foam Sponge Carbide Blades Inserts Milling Turning Plastic Boxes

CNC Internal Hole Deep groove Insert Small Grooving Comma Cutter Head MB-05GR100- R0.5 Arc Corner Grain Cnc Blade

Новые поступления

Новинки товаров от производителей по оптовым ценам