Высококачественная плоская Луженая прочная батарея луженая медная шина для распределительного

- Категория: >>>

- Поставщик: Zhejiang Rhi Electric Co. Ltd.

Сохранить в закладки 878315863:

Описание и отзывы

Характеристики

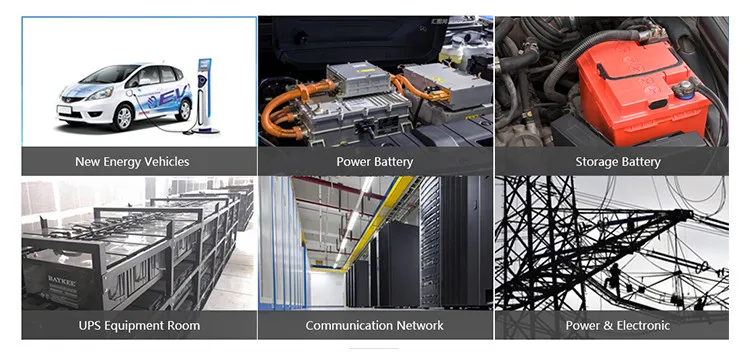

High quality flat tinned solid battery tinned copper busbar for power distribution cabinet/box

Solid copper busbar is made of copper C110. It is processed by stamping, CNC bending, finish treatment and insulaiton. The busbar finish can be bare copper, tin plating, nickel plating and silver plating.The insulation can be PVC, PE heat shrink tube, epoxy powder coating and PA12. Sizes and shapes can be customized according to customer's request. Our technicians also can assist customers to design and develop prototypes. With copper bus bars, customers can eliminate wiring errors and reduce assembly costs.

| Material Standard | GB : T2 Copper with Min. 99.9% DIN: E-Cu58 (Number: 2.0065) EN: Cu-ETP ( Number: CW004A) ISO: Cu-ETP UNS: C11000 JIS: C1100 BS: C101 Other Material also can be customized |

| Resistance | 0.00001Ω |

| Conductivity | 57% |

| CopperThickness | 1/2/3/5/10mm,depend on bus bar structure, we will advise suitable thickness |

| Insulation Material | PVC Dipping Coating is good performance, Special shaped bus bar can be put on directly, it is not easy to break when it be bent with many times. |

| Insulation Performance | PE and PVC are good, PVC dipping is better than PE heat shrink tubes |

| Flame Retardant/Fire Resistance | UL94-V-0 or upon you request |

| Leakage Testing | PVC Dipping Sleeves: In condition of 3500VDC with 30s upon thickness 1.5mm, Leakage is 0.025 MA; In condition of 5000 VAC with 30s to 60s upon thickness 1.8mm to 2.0mm, Leakage is 0.065 MA; Or upon your working voltage, we advise to choose better solution. |

| Surface Plating | Nickel, tin or silver plated etc Plating Thickness:Normally 3um to 12um or upon customers' request |

| Salt Spray Testing | In a neutral environment, nickel can bear 240 hours. Silver is lower, tin is lowest |

| Bending Testing | Bend 10000 times in 15 radian angle without breakage or fracture. |

| Temperature Rise Testing | Depend on flexible busbar cross-sectional area, We can offer all temperature rising test report before delivery if you request |

| Operating Temperature | -45 to +150 ºC |

| Tensile Strength | ≥500N |

| Quote Time | Quotation sheet will be sent in 1-3 working days when receive your enqiury |

| Sample/Trial Order Delivery Time | In 5 -15 working days according to different bus bar structure and manufacture process |

| Quality Management Standard | Meet Auto Industry IATF 16949 |

| Eco-friendly Certificate | ROHS, REACH |

|  |

1.Perfect management systems: Implement ISO9001 & IATF16949 and provide PPAP document.

2.Professional sales team:more than 6 year export experience and 24-hour service line to meet customer’s need.

3.Premium quality:test from raw material to packaging and many advanced testing equipments,like temperature tester,electrical conductivity tester.

4.High production efficiency and low cost :10 year experience of production and complete production chain.

5.Highly intelligent production workshop: robot production line and high-precision machines.

Testing Capabilities

| Test Programs | Tester | Standard | Test Result |

| Endurance test | Endurance meter | upon your request | √ |

| Release force test | Universal material testing machine | upon your request | √ |

| Loop resistance,contact resistance test | Loop resistance testing equipment | upon your request | √ |

| Temperature rising test | Temperature rising tester | GB/T14048.1-2000 | √ |

| Electric conductivity test | Conductivity tester | YS/T478-2005 | √ |

| Salt spray test | Salt spraying tester | GB/T2423.17-2008 | √ |

| Thermal ageing, heat vibration test | Air exchange aging test machine | upon your request | √ |

| Coating thickness test | X-ray coating thickness tester | upon your request | √ |

| Voltage drop test | Voltage drop tester | upon your request | √ |

Contact person: Maria zhou

Mobile:86-15138343375

Linkedin: Chou Maria

Wechat:86-15138343375

Похожие товары

Запчасти для ходовой части экскаватора, сборка экскаватора, верхний переносной ролик, тяжелое оборудование и запасные части для машин

Экскаватор E 200B, экскаватор, 2-й носитель, мотор, запасные части, запчасти для экскаватора, финальный привод

ZOOMLION гусеничный кран запасные части QUY70 ZCC750 ZCC750H опорный ролик сборка 1031400005

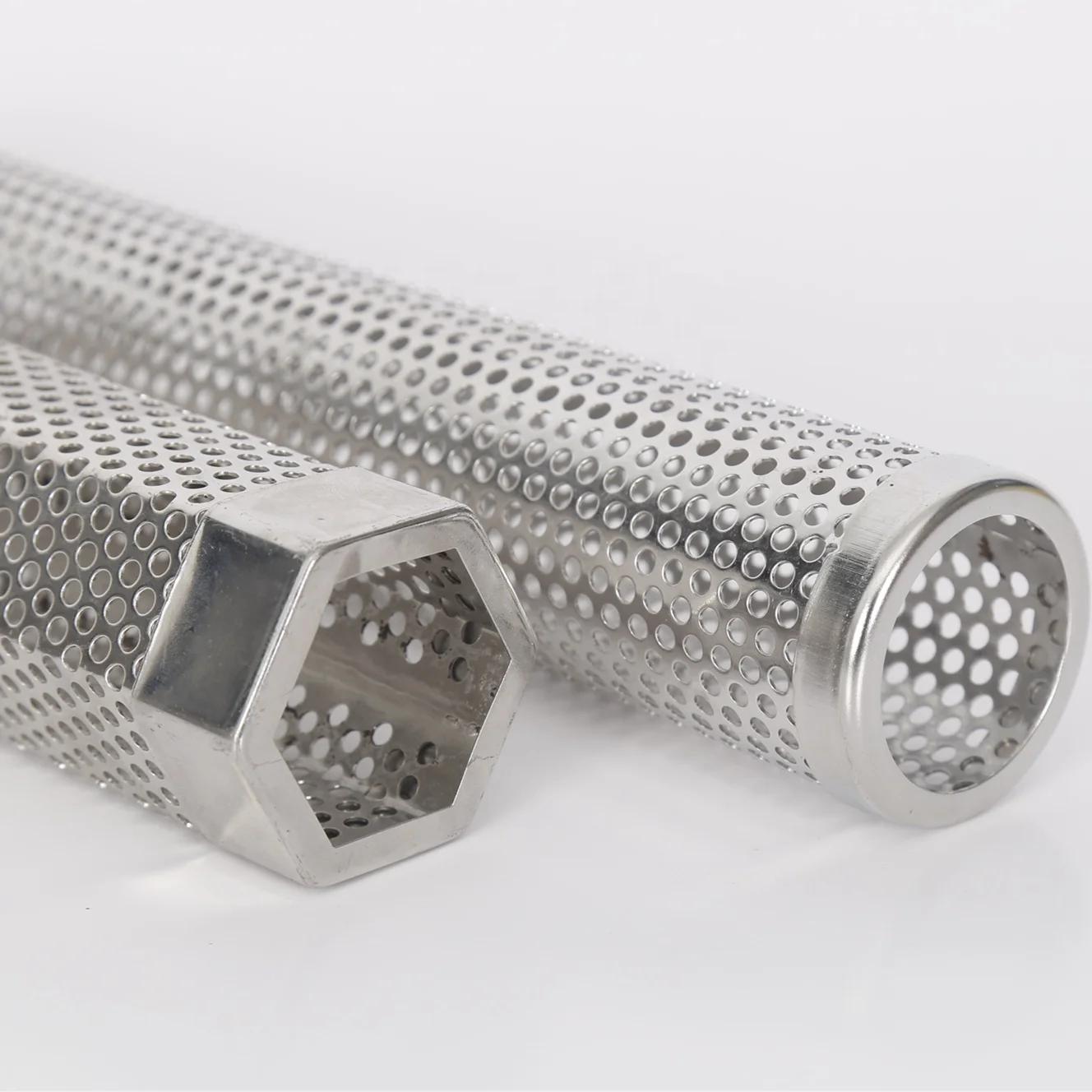

Высококачественная трубка для курильщика в виде гранул генератора барбекю 12

Блок управления линейным приводом Max 5000N 12 В

Устойчивый металлический каркас и сетчатая полка VASAGLE шестиугольный винтажный журнальный столик чайный для гостиной

Лидер продаж, блок питания для HP ProLiant ML350 G4, 725 Вт, горячий разъем, 345875-001, 365063-001, 358352-001

Новые поступления

Новинки товаров от производителей по оптовым ценам