TH 120E стелька доски/EVA лист/ПУ/кожи машины для прослаивания джинсовой ткани

- Категория: >>>

- Поставщик: Shantou Hongji Machine Equipment Co. Ltd.

Сохранить в закладки 898192611:

Описание и отзывы

Характеристики

TH-120E Fabric Laminating Machine

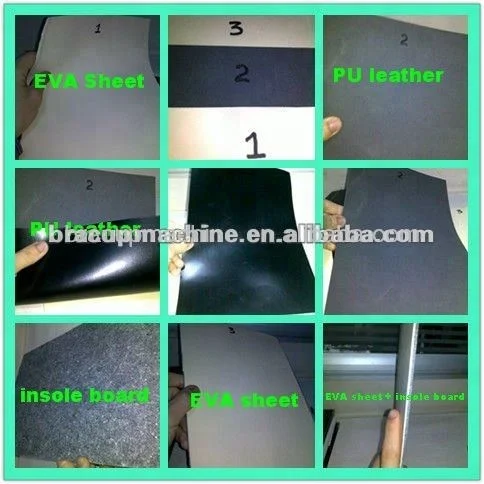

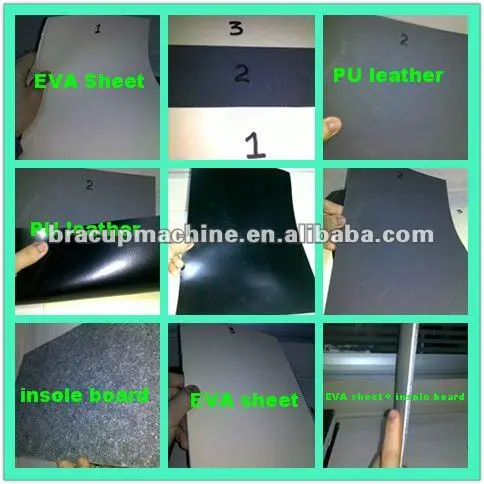

Function: Mainly used to laminate and glue foam/sponge, fabric materials, EVA sheet, insole board, PU leather/ synthetic leather, and other similar raw materials for underwear/lingerie industry, shoemaking, hatting, gloves, handbags, coat, sofa, car seat cushion.

Features:

(1) The design of the complete machine emphasizes on the stable performance and secure supervision.

(2) According to the request of the cloth and the glue, a variety of specification chromium rollers are made by measurement, which improved the lamination quality effectively and decreased the glue consumption.

(3) It adopts the steel belt of high temperature resistance on hard chromium roller and the process of pressing cloth proceeds evenly.

(4) This model is the result based on absorbing the merits from other vertical single glue groove laminating machines (TH-120A) and getting some improvements for traditional spring pinch rollers.

Technical parameters:

Power supply / power | 380V/35KW |

Motion | 3HP+2HP |

Specification of heating rollers | Φ1200mm×1830mm |

Working width | 1700mm |

Working speed | 30yards/min |

Machine size | 7200×2600×2400mm |

Weight | 3000kg |

Merits:

1. unique and reasonable way to glue-coating makes the glue put evenly;

2. save much glue dosage. It can be processed by water and oil-based glue.

3. characteristics such as: soft, good texture, water-proof, ventilate and dry-cleanable.

We are the 1st professional manufacturer & supplier of underwear machinery in Shantou, China Mainland. Besides, we also have own bra cup factories located in Xiamen City and Dong Guan City. We can supply 400~500 sets of machinery monthly, and 1.5~2.0 million pairs of bra cups/ bra pads in each factory.

1. MOQ: 1 set

2. OEM & ODM can be acceptable.

3. We own all the original R & D Technology and Proficient Experience in this field over 13 years.

4. All the Moulds can be customized according to your supplied samples.

CNC Made or Manual Made to be Optical.

5. The Molding Table Size can be bigger customized if required.

6. The Molding time and temperature can be preset and adjusted freely through the timers and temperature controllers when we mold / press different materials.

7. All the digital meters are easy to operate.

8. All the spare parts can be matched to supply.

9. All the electric fittings and pneumatic parts used in our machinery are with high-quality.

10. All the raw materials (machine frame, machine fittings and etc) are processed by our own factory.

11. We guarantee there is absolutely without jerry-built.

12. Good & Timely After-Sale Services.

If above details are still not clear for you, kindly please contact me without delay!

Looking forward to cooperating with you for long term!

Похожие товары

KV-168D/D-10 индустрии нижнего белья бюстгальтер производство ткани стакан литьевой машины

KV-168D/D-9 формы для пули формовочная машина тканевого бюстгальтера

Vulcan FC700 автоматический планшетный резак машина Планшетный картонный пакет коробка цифровой режущий плоттер

YB-210B ткани с высоким качеством цифрового печати контрольно-измерительная машина

Энергосберегающая Светодиодная лампа для швейной машины 30 шт.

Новая вышивальная машина компьютерная Feiya 1 головка Swf

Высокоэффективная машина для проверки и прокатки ткани с функцией резки

Новые поступления

Новинки товаров от производителей по оптовым ценам