Сэндвич панель из полиуретана для холодной комнаты толщиной 200 мм с огнестойким материалом

- Категория: >>>

- Поставщик: Guangdong Dachang Energy-Saving Insulation Technology Ltd.

Сохранить в закладки 939485485:

Описание и отзывы

Характеристики

200mm thickness cold room polyurethane sandwich panel with fire rated material

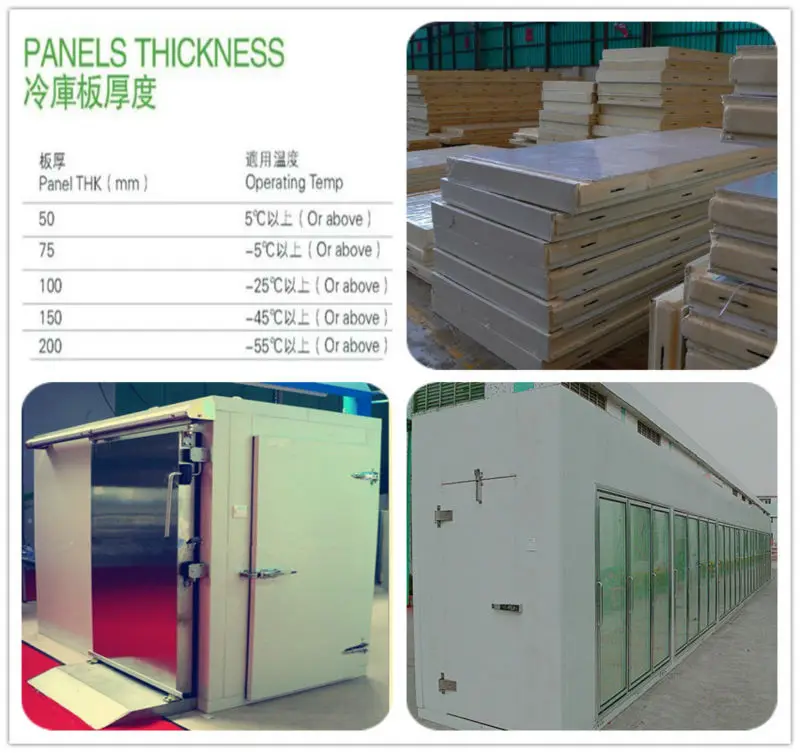

cold storage panel is used with BASF polyurethane foam material,which is constructed by being foamed in place with retarted Polyurethane using high pressure.They have certain dimensions.Standard widths of panels are a multiple of 295.3mm. The maximum lengths of panels are 13.5m.Non-standard sizes are also available upon request with price varying.

cold storage panel features:

1. Cold room panel is durable in use, color lasting & coated layer keeping.

2. It is made with Bayer polyurethane material by high pressure foaming. The cold room panel density is

up to 43kg/m3 or above.

3.The maximum length of cold room panel is 13.5m and the standard width is 295.3mm with fire resistance.

4. The internal cold room floor panel is made by 1.0mm galvanized steel and durable for anti-scratch.

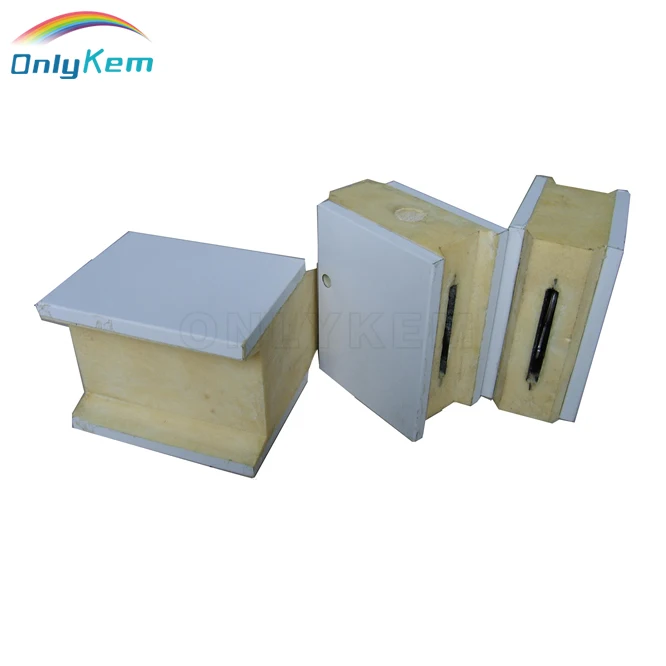

5. The hinged door panel is made by heavy duty door hinge, heavy duty door lock and hydraulic door closer.

6. The connection of our cold room panel is made with PE sealing rubber which is with high quality sealing.

7. The connection of our cold room panel is with cam lock construction and excentric fasterners for tight

connection and sealing of the cold room

cold storage panel specification:

| Panel | Polyurethane insulation panel,43kg/m3,fire resistance |

| Foaming material | BASF |

| Panel thickness | 50mm,75mm,100mm,150mm,200mm |

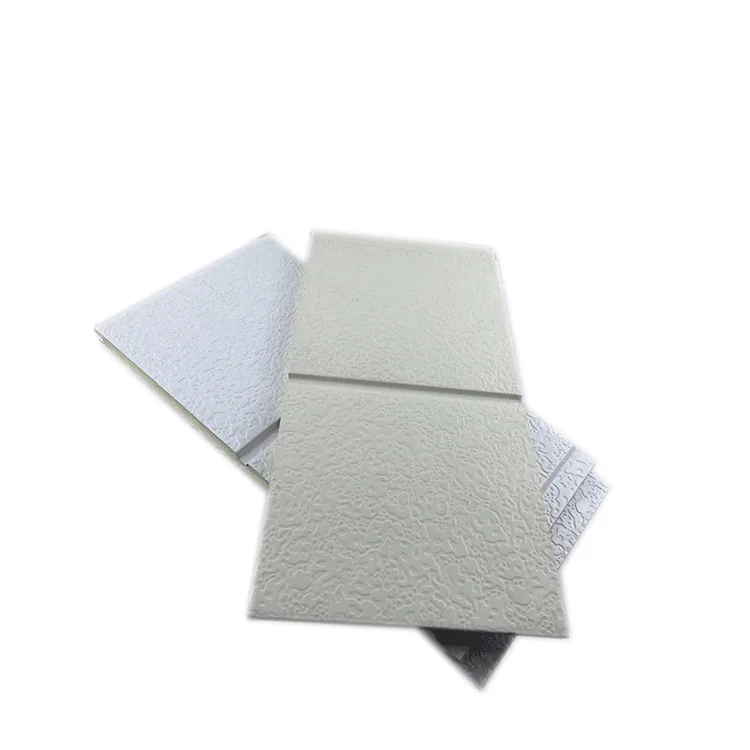

| Steel cover | Stucco embossed aluminum,Painted galvanized steel,Stainless steel |

| Panel connection | Cam lock type,use hexagonal key to assemble and disassemble |

cold storage panel introduction:

1.Cold room panel test specification

| No. | Inspection Item | Unit | Technology requirement | Inspection result |

| 1 | Density | kg/m3 | 32~50 | 43 |

| 2 | Compressing strength(10%deformation) | Kpa | ≥ 160 | 200 |

| 3 | Bending Stregth | Kpa | ≥ 245 | 331 |

| 4 | Absording rate | % | ≤ 4 | 3 |

| 5 | Heating coefficient | W/m.k | 0.024 | 0.021 |

| 6 | Average burning time(vertical) | S | ≤ 30 | 3 |

| 7 | Average burning height(vertical) | s | ≤ 250 | 250 |

2. cold storage panel advantages:

1. Our panel foaming material is Germany Brand BASF . The whole panel average density above 43kg/m3 which enable the panel with better thermal conductivity of 0.021W/(m.k). The national standard is 0.024W/(m.k), which mean our panels will save the energy consumption of 12.5% than national standard.

2.All the panels we produce are with fire retardant, self extinguish, Fireproofing Grade is B1. It refers to the safety

problem.

3.The steel sheet we purchase from Baosteel and POSCO which are the biggest steel factories in the world, they promise the painted galvanized steel they produce will not fade in 15~20 years

4.Gasket is around the edge of each panel , when panel lock together,the cool air will not leak,and the hot air can not come in.

3. cold storage panel

surface material: painted galvanized steel, stucco embossed aluminum, stainless steel, PVC stell

4. cold storage panel of floor

The internal cold room panel of floor is made by 1.0mm galvanized steel and durable for anti-scratch.

5. cold storage panel installation

panels are female and male type, cam lock is pre-burried inside the panel, use a hexagonal key to lock them tight.

6.cold storage panel package

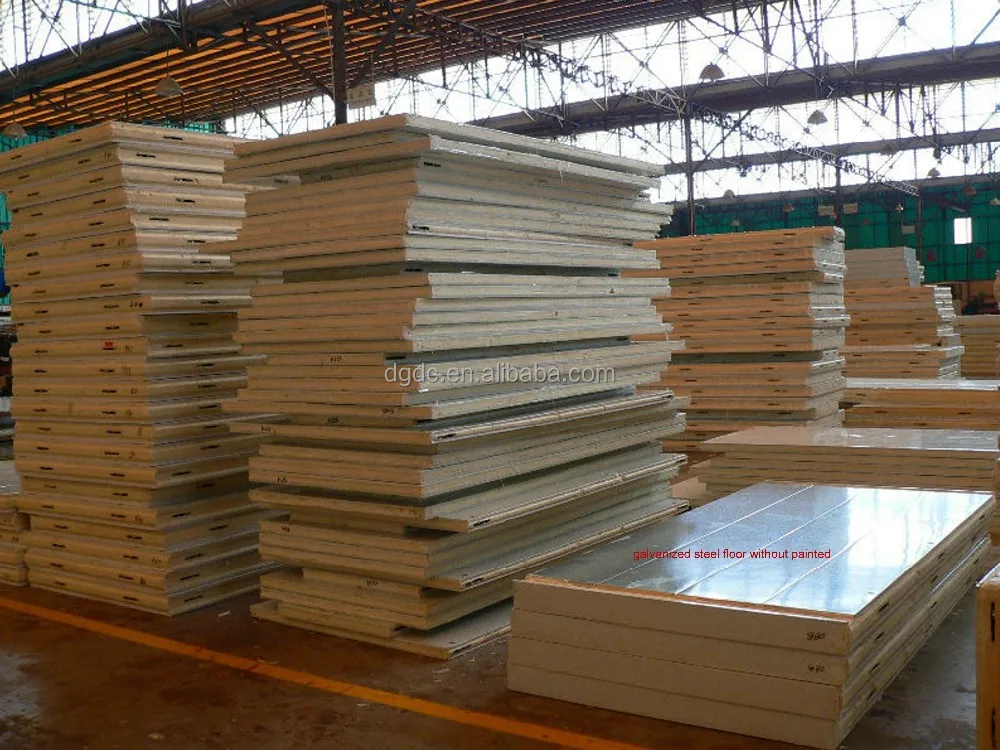

7. cold storage panel loading

8. cold storage panel production procedure

cold storage panel exhibition:

cold storage panel certificate:

cold storage panel Factory picture:

Похожие товары

Китайская дверь 5D Неокрашенная Бесшумная деревянная дверь

Внутренние деревянные двери из чистого дуба в китайском стиле, водонепроницаемые и влагостойкие дверные рамы, цельные межкомнатные деревянные двери

Крыша для холодного хранения стен внутренняя и наружная изоляционная панель полиуретановые PU Сэндвич-Панели

Китайские фабрики хорошего качества новые твердые деревянные спальни гостиной ванной двери

Китай игрушки самолет поставщиком электрической больших самолетов RC RTF B-2 может опускаться Бомбочки для взрослых

Insulated Polyurethane PU Sandwich Panel Wall Cold Room Panel

Изолированная полиуретановая кровельная сэндвич-панель, металлическая сэндвич-стеновая панель, Прямая поставка с завода

Новые поступления

Новинки товаров от производителей по оптовым ценам