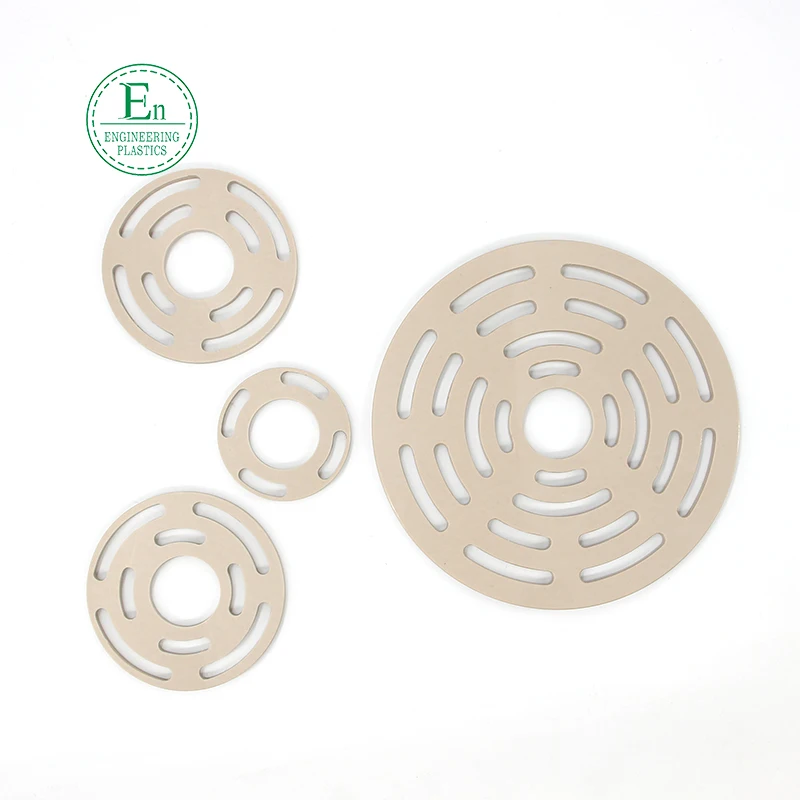

High temperature special engineering injection molding plastics customize PEEK Valve parts

- Category: Other Plastic Products >>>

- Supplier: Guangzhou Engineering Plastics Industries (group) Co. Ltd.

Share on (1600447739726):

Product Overview

Description

PEEK Valve Product Description

PEEK(Polyetheretherketone)is a kind of heat-resistant, high performance thermoplastic special engineering plastics. It has good mechanical properties and chemical resistance, abrasion resistance, and hydrolysis resistance properties etc.; it has a light proportion and self-lubricating properties. Guangzhou Engineering Plastics Industries (Group) Company, has studied and applied this material in many industries for many years. Due to very good processing properties, it can be filled with carbon fiber, Fiberglass and MoS2 etc. In order to improve lubrication performance and mechanical strength further.

Characteristics

Application

PEEK Valve Product Display

PEEK Material features

Mechanical properties (variable stress and excellent fatigue resistance)

High temperature resistance (long-term use at 2600C)

Self-lubricity (low coefficient of friction and wear resistance)

Chemical resistance (corrosion resistance)

Flame retardant (can reach the highest flame retardant standard)

Peeling resistance (can be made into thin coated or electromagnetic wire)

Fatigue resistance (resin material has the best fatigue resistance)

Hydrolysis resistance (excellent in high temperature and high pressure water)

Radiation resistance (up to 1100Mr AD)

Mechanical properties (variable stress and excellent fatigue resistance)

High temperature resistance (long-term use at 2600C)

Self-lubricity (low coefficient of friction and wear resistance)

Chemical resistance (corrosion resistance)

Flame retardant (can reach the highest flame retardant standard)

Peeling resistance (can be made into thin coated or electromagnetic wire)

Fatigue resistance (resin material has the best fatigue resistance)

Hydrolysis resistance (excellent in high temperature and high pressure water)

Radiation resistance (up to 1100Mr AD)

Appliacation

Certification

Companies strictly enforce the ISO9001(2008)international quality certification system,

the product quality conforms to the eu RoHS standard.

Professional Team

Our Factory

Specializing in the production of "engineering plastic accessories" of high-tech enterprises,

the company has a set of imported production equipment and CNC processing equipment,

processing means advanced, strong technical force.

the company has a set of imported production equipment and CNC processing equipment,

processing means advanced, strong technical force.

Exhibition & Our Strength

Our company has rich experience, strong strength and participated in many high-level exhibitions. Many partners from other countries are visiting

cooperation

Buying Instructions

Q1. We don't have drawings, can we produce according to the samples we provide?

A1. OK

Q2.How to customize plastic parts?

A2. Customized according to drawings

Q3. Can I make a sample for testing first?

A3. OK

Q4. How long is the proofing cycle?

A4. 2-5 days

Q5. What are your processing equipment?

A5. CNC machining center, CNC lathe, milling machine, engraving machine injection molding machine, extruder, molding machine

Q6. What craftsmanship do you have for processing accessories?

A6. According to different products, different processes are used, such as machining, extrusion, injection molding, etc.

Q7. Can injection products be surface treated? What are the surface treatments?

A7. OK. Surface treatment: spray paint, silk screen, electroplating, etc.

Q8. Can you help asse mbling the product after it is made?

A8. OK.

Q9. How much temperature can the plastic material withstand?

A9. Different plastic materials have different temperature resistance, the lowest temperature is -40°C, and the highest te

mperature is 300C. We can recommend materials according to the working conditions of your company.

Q10. What certifications or qualifications does your company have?

A10. Our company' s certificates are: ISO, Rohs, product patent certificates, etc.

A1. OK

Q2.How to customize plastic parts?

A2. Customized according to drawings

Q3. Can I make a sample for testing first?

A3. OK

Q4. How long is the proofing cycle?

A4. 2-5 days

Q5. What are your processing equipment?

A5. CNC machining center, CNC lathe, milling machine, engraving machine injection molding machine, extruder, molding machine

Q6. What craftsmanship do you have for processing accessories?

A6. According to different products, different processes are used, such as machining, extrusion, injection molding, etc.

Q7. Can injection products be surface treated? What are the surface treatments?

A7. OK. Surface treatment: spray paint, silk screen, electroplating, etc.

Q8. Can you help asse mbling the product after it is made?

A8. OK.

Q9. How much temperature can the plastic material withstand?

A9. Different plastic materials have different temperature resistance, the lowest temperature is -40°C, and the highest te

mperature is 300C. We can recommend materials according to the working conditions of your company.

Q10. What certifications or qualifications does your company have?

A10. Our company' s certificates are: ISO, Rohs, product patent certificates, etc.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices