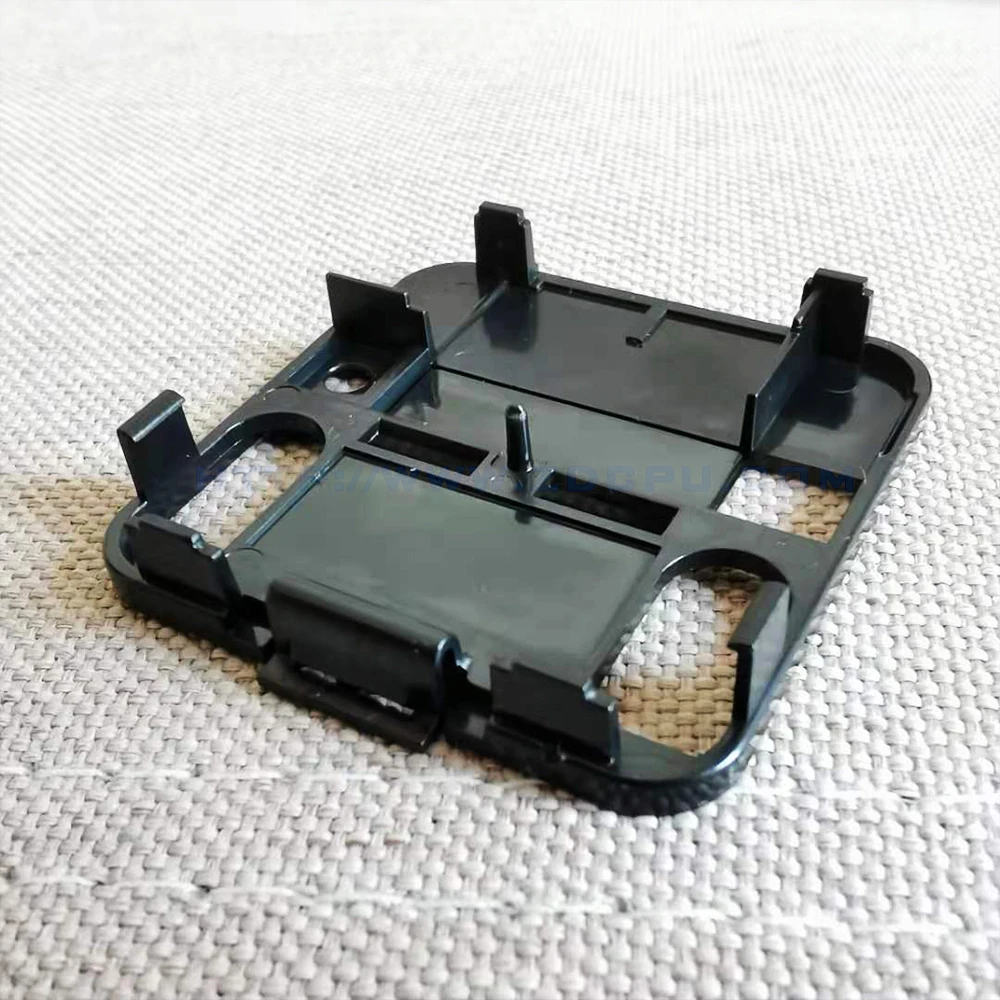

Custom Large Abs Plastic Enclosure / Junction Box / Cover Injection Molding

- Category: Other Plastic Products >>>

- Supplier: Zhongde (Beijing) Machinery Equipment Co. Ltd

Share on (1600875730501):

Product Overview

Description

Technology

Rubber Injection molding

Plastic Injection molding

Over&insert molding

Compression molding

Urethane cast molding

CNC machining

Extruded

Vacuum forming

Our Services

Product Design

Mold Making

Material Modification

Logo Printing

Surface Treatment

Assembly

Custom Packaging

Door to Door Delivery

Product Description

Material | PA6 PA66 PA6+GF PA66+GF, ABS, POM, PP, PE, LDPE, HDPE, UHMWPE, PTFE, PVC, PC, PEEK, PS, PET, PBT, TPU, TPE,etc |

Color | Black, white, red, green, transparent or any color according to Pantone code |

Size | As per customer's requirements |

Biggest Part Size | 1500*1500*1000mm |

Tolerance | 0.01mm--0.001mm |

Product Volume | 50,000,000 Pcs/Month |

Drawing Format | 2D Drawing: PDF/JPG/PNG 3D Drawing: STEP/STP/IGS/DXF/DWG |

Technology | Injection molding, CNC machining, Extrusion, Compression Molding |

Surface Treatment | Powder coating, Zinc coating, Galvanization, Electro-deposition coating, Chrome/zinc/nickel plating, Polishing, Silkscreen, Black oxide |

Application | Automotive, ATV, Mechanical equipment, Construction, Home appliance, Aviation, Office facilities, Agriculture, etc. |

Shippment | 15-25 days for mouldmaking , and partsdelivery time is dependson quantity of production We have longterm cooperation with internation shipping agent and express company, so that shipping safty and arriving time are secured |

WHY US

COMPREHENSIVE MATERIALS

Stock more than 50 types of materials, Zhongde is able to supply the most common plastic and rubber materials in the market. We also provide material modification services for unique using environments.

CONSIDERATE SERVICE

Our engineers will work 24/7 with you throughout your project. Together, we will discuss your unique design and help you optimize the parts, and also provide DFM reports if required.

REASONABLE PRICE

Our quote includes real-time pricing and design analysis. We evaluate your 3D CAD and help identify any features that may pose challenges during the molding process. Ensure that each quote is Well-founded.

STRICT QUALITY CONTROL

ISO and SGS certified manufacturer. Our professional quality control departments strictly inspect every process of mold and production, and each problem can be traced back. Reduce error correction time and our defective rate as low as 1%

Stock more than 50 types of materials, Zhongde is able to supply the most common plastic and rubber materials in the market. We also provide material modification services for unique using environments.

CONSIDERATE SERVICE

Our engineers will work 24/7 with you throughout your project. Together, we will discuss your unique design and help you optimize the parts, and also provide DFM reports if required.

REASONABLE PRICE

Our quote includes real-time pricing and design analysis. We evaluate your 3D CAD and help identify any features that may pose challenges during the molding process. Ensure that each quote is Well-founded.

STRICT QUALITY CONTROL

ISO and SGS certified manufacturer. Our professional quality control departments strictly inspect every process of mold and production, and each problem can be traced back. Reduce error correction time and our defective rate as low as 1%

Company Profile

Zhongde is a leading manufacture of OEM parts in rubber & plastic & metal parts. We are always pursuing providing better quality products in shorter period. With a knowledgeable team which has experience in molding and production, we are confident to help you develop and manufacture your product

We have different types of machines to meet different requriements. Most our machines were imported from overseal. The highest rotate speed of CNC machining center can reach to 20,000RPM. The largest vulcanize rubber machine can produce rubber parts within 3000mm.

WEDM

EDM

Injection Molding Machine

Large Flat Vulcanizing Machine

Automatic Vulcanizing Machine

Vulcanizing Injection Machine

Product Range

Zhongde products range from mold to rubber & plastic & metal parts. We can also design drawing according to its applications or customers requirement.

Customer Photos

Packing & Shipping

Product Packaging

Packaging:

Normally the goods are packaged as the picture shows, or it can be as customized

Shipping

We will discuss with our customers to choose the suitable shipping method for goods.

FAQ

Q1. Are you factory or trade company?

A: We are both, we have our own factory and we can export by ourself.

Q2. What kind of payment do you accept?

A: Trade assurance, T/T, L/C, Weston Union are all accepted.

Q3. What is normal lead time?

A: Average 15-25 days for tooling, bulk orders should be depends on quantity.

Q4. What is your standard package?

A: In general we use ziplock bag or bubble file plus cardboard boxes, wooden pallets or wooden cases will be used if necessary,. Special packing method is available if needed.

Q5. What is the working life of the mould?

A: It depends on the parts we made. Besides, we will maintain or replace the mould be ourselves.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices