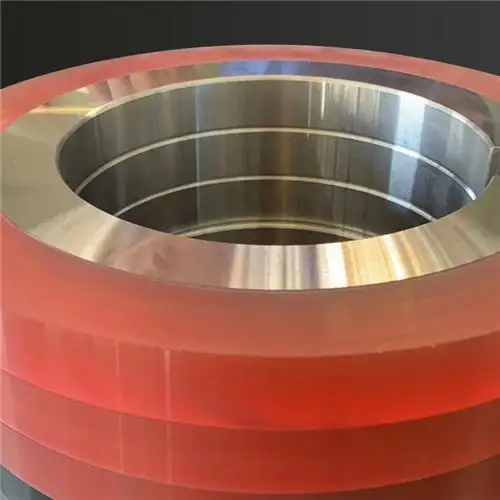

Friction drive rubber wheel polyurethane/ Polyurethane rubber ring

- Category: >>>

- Supplier: Maanshan Linbin Precision Machinery Biade Co. Ltd.

Share on (1600645467959):

Product Overview

Description

Product Overview

What are the advantages of polyurethane

1、 High temperature resistance Under high temperature conditions, polyurethane is still the first choice for high-pressure

hydraulic systems. The rated temperature of polyurethane is more than 120 ℃, and it can withstand 5000 psi or even higher pressure

at the same time. This extreme combination makes polyurethane a leader in similar products of hydraulic cylinders. Although

fluororubber can easily handle temperatures above 200 ℃, its pressure bearing capacity is poor, usually limited to 2000 psi or

even lower.

hydraulic systems. The rated temperature of polyurethane is more than 120 ℃, and it can withstand 5000 psi or even higher pressure

at the same time. This extreme combination makes polyurethane a leader in similar products of hydraulic cylinders. Although

fluororubber can easily handle temperatures above 200 ℃, its pressure bearing capacity is poor, usually limited to 2000 psi or

even lower.

2、 High strength and toughness

Due to its good hardness and toughness, polyurethane seals have excellent extrusion resistance. In addition, excellent hydraulic seals must be resistant to shearing and tearing. Under the action of pressure, hydraulic oil can easily break through the defense line of inferior seals. Polyurethane will deform under pressure to adapt to the change of clearance, thus ensuring reliable sealing; When the pressure is removed, its high strength characteristics can restore it to its original shape instead of producing permanent deformation.

Due to its good hardness and toughness, polyurethane seals have excellent extrusion resistance. In addition, excellent hydraulic seals must be resistant to shearing and tearing. Under the action of pressure, hydraulic oil can easily break through the defense line of inferior seals. Polyurethane will deform under pressure to adapt to the change of clearance, thus ensuring reliable sealing; When the pressure is removed, its high strength characteristics can restore it to its original shape instead of producing permanent deformation.

Right elevation

Left elevation

Front elevation

3、 High wear resistance

Fluid contamination is a common symptom of hydraulic systems. When particles erode the seals, there is a risk of premature seal failure. However, polyurethane benefits from its natural high wear resistance, which is much better than other polymers such as nitrile rubber and fluororubber.

Fluid contamination is a common symptom of hydraulic systems. When particles erode the seals, there is a risk of premature seal failure. However, polyurethane benefits from its natural high wear resistance, which is much better than other polymers such as nitrile rubber and fluororubber.

SIMILAR PRODUCTS

SALES AND SERVICE NETWORK

FAQ

Q: Are you a factory or a trading company?

A: We have our own factory.

Q: When is your delivery time?

A: It depends on your order quantity and processing difficulty

Q: What process do you have for processing accessories?

A: Different processes are used according to different products, such as machining, extrusion, injection molding, etc

We Recommend

New Arrivals

New products from manufacturers at wholesale prices