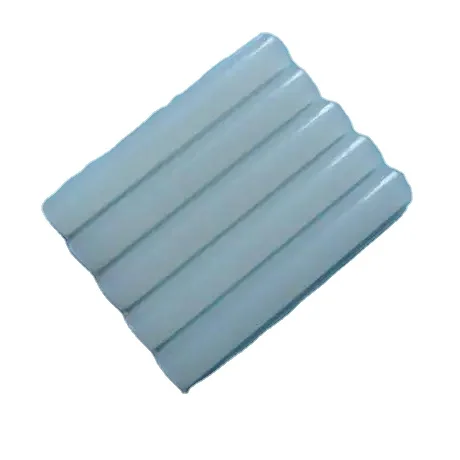

FLUOROELASTOMER DAI EL G 912

- Category: Fluorocarbon Rubber >>>

- Supplier: Zhangjiagang Greata International Co. Ltd.

Share on (1600736222232):

Product Overview

Description

Product Description

Specification

item | value |

Place of Origin | China |

Packing & Delivery

According to the buyer requests for packaging

Company Profile

The properties of DAI-ELLT-302 elastomer, a disadvantage of the previous ammonia containing elastomer, have been improved. It provides excellent mechanical properties, bending and acid resistance. In particular, the TR10 material is - 31 ℃, providing excellent low-temperature sealing performance.

1. Properties of raw rubber

Item Description Data Test Method

Visual inspection of translucent or light yellow appearance

Fluorine concentration 64.5 mass%

Specific gravity in accordance with (23 ℃) 1.80 JIS K6268

Mooney viscosity (ML 1+10-100 ℃) about 68 JIS K6300-1

Solubility Easily soluble in low molecular weight ketones and esters

2. Physical properties (curing)

Test method and conditions of project unit data

Conform to 100% tensile stress MPa 2.4 JISK 6251

Side arm extension and MPa_ 1.9 0O.

It meets the growth rate of 290 JISK6251

Compression permanent deformation% 25 200 ℃ X70h, 25% compression

Hardness (Shore peak) 65 acc. to JS K 6253

*The above values are representative and cannot be guaranteed.

(Compound preparation)

DAI-EL LT302 100 copies

MT carbon black * 1 20 copies * 1 Temax N990Cancarb Co., Ltd

Ureate * 2, 3 parts * 2 TAIC Kasei Co., Ltd

PERHEXA 25R * 7 1 piece 43 PERHEXA 25RNEO

(curing conditions)

Pressurized vulcanization 160 ℃ x 10 minutes Oven vulcanization 180 ℃ x 4 hours

5 Precautions for using DII-EL

When vulcanizing DAI-EL and using vulcanized rubber under high temperature, a small amount of gas harmful to human body will be produced, so indoor ventilation must be fully paid attention to. Because toxic gas will be generated, it is not allowed to dispose of the scraps by burning. If it needs to be discarded, please handle it safely according to relevant national laws. If this product is attached to cigarettes, you will inhale toxic gas when smoking. Therefore, you should wash your hands and face after work. Please be careful not to attach the product to cigarettes. If metal particles such as amine powder are used as ingredients, they will decompose violently at high temperatures, so do not use metal particles as ingredients.

Fe-271-u is fluorosilica gel produced by shinyue chemical, Japan. It is gray white, vulcanizing agent c-8a, hardness 73, elongation 300%, tensile strength 9.0MPa, tear strength 16, linear shrinkage 3.5%, rebound 34%, compression set 9%, and has good physical properties. As fluorosilica gel, it has excellent heat resistance, cold resistance, processability and solvent resistance. The standard oil irm903 shows swelling below 5% (150 ℃ / 70 hours). In addition, it also has good resistance to silicone oil

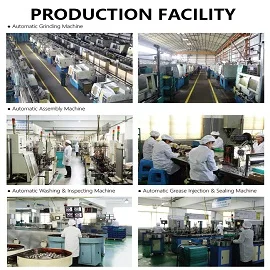

As a member of Excellence Production Union (Youpin Union--UPU), we have reached another high peak in our development. Now our products like kitchen cabinets, railings, murphy beds, bathroom cabinets, doors and lamps and other building materials have spread all over the world.

For more information, please visit our website.

Our highly trained technicians will install and set up each furniture and train your personnel on all facets of the machine's operation and maintenance.

We sincerely welcome both domestic and international friends to cooperate with us.

FAQ

1. who are we?

We are based in Jiangsu, China, start from 2012,sell to Mid East(20.00%),Western Europe(15.00%),Southern Europe(15.00%),Eastern Europe(10.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

titanium pipe,titanium bar,bearings,titanium plate,forged steel ring

4. why should you buy from us not from other suppliers?

Business Type: Manufacturer, Trading Company Verified

Location:Jiangsu, China (Mainland)Verified

Main Products:titanium tube,titanium pipe,titanium plate,titanium rod,titanium bar, bearings

Total Employees:11-50

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency:USD,EUR,JPY,AUD,HKD,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,Portuguese,German,Arabic,French,Russian,Korean,Italian

We are based in Jiangsu, China, start from 2012,sell to Mid East(20.00%),Western Europe(15.00%),Southern Europe(15.00%),Eastern Europe(10.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

titanium pipe,titanium bar,bearings,titanium plate,forged steel ring

4. why should you buy from us not from other suppliers?

Business Type: Manufacturer, Trading Company Verified

Location:Jiangsu, China (Mainland)Verified

Main Products:titanium tube,titanium pipe,titanium plate,titanium rod,titanium bar, bearings

Total Employees:11-50

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency:USD,EUR,JPY,AUD,HKD,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,Portuguese,German,Arabic,French,Russian,Korean,Italian

Title goes here.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices