Пероксидный отверждаемый FKM отвержденный FKM сырьевой материал пероксидный отверждающий фторэластомер для компрессионного переноса инжекционного экструзионного формования

- Category: Fluorocarbon Rubber >>>

- Supplier: Jiangsu FreChem Co. Ltd.

Share on (1600868488324):

Product Overview

Description

Product Description

FKM FPM(Foluroelastomer)

Foluroelastomer is very stable and possess exceptional resistance to oxidation, weather, flame, oil, chemical attack and swelling in a wide range of liquids. Fluorocarbon exhibits resistance to a broad range of chemicals combined with very good high temperature properties more so than any of the other elastomers. It is the closest available approach to a universal elastomer for sealing in the use of O-rings and other custom seals over other types of elastomers. FKM can be classified in many subgroups according to:

1. Fluorine content: general type (A—66%), middle fluorine content type (B&GBL—69%), high fluorine content type (F&GF—70%), improving low temperature flexibility type (GLT, GFLT) and excellent resistance to more chemicals and solvents (ETP & FFKM). The higher the fluorine content the better the chemical resistance.

2. Polymer: A—dipolymer, B, F and GF—terpolymer.

3. Cure system: standard FKM compounds are bisphenol cured. FKM compounds with peroxide-cured possess better acid solution resistance than the bisphenol cured.

1. Fluorine content: general type (A—66%), middle fluorine content type (B&GBL—69%), high fluorine content type (F&GF—70%), improving low temperature flexibility type (GLT, GFLT) and excellent resistance to more chemicals and solvents (ETP & FFKM). The higher the fluorine content the better the chemical resistance.

2. Polymer: A—dipolymer, B, F and GF—terpolymer.

3. Cure system: standard FKM compounds are bisphenol cured. FKM compounds with peroxide-cured possess better acid solution resistance than the bisphenol cured.

Specification

Product Technical Property of FKM Raw Gum

FKM raw gum copolymer

Items | C20 | C30 | C40 | C50 | C60 | C70 | C120 | ||||||

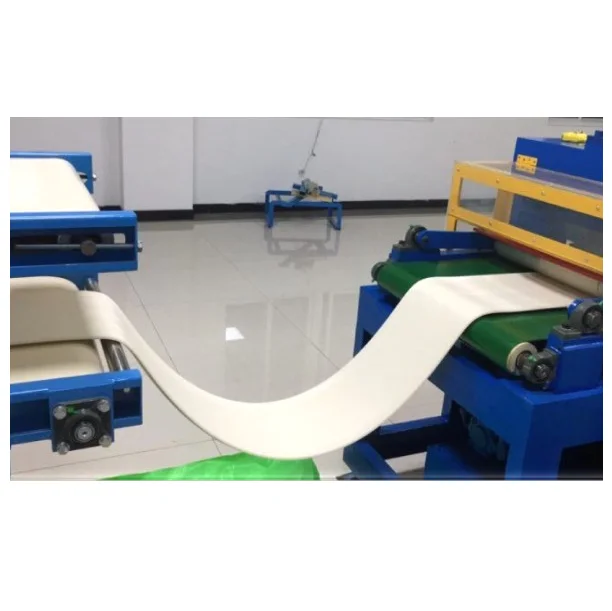

Appearance | White or light-yellow sheet, no visible impurities | ||||||||||||

Density (g/cm3) 23 °C | 1.82±0.02 | 1.82+0.02 | 1.82+0.02 | 1.82+0.02 | 1.82+0.02 | 1.82+0.02 | 1.82+0.02 | ||||||

Mooney viscosity (ML(1+10) ,121°C) | 20-30 | 30-40 | 40-50 | 50-60 | 60-70 | 70-120 | 120-180 | ||||||

Tensile strength after press cure(MPa) 170°C,10min≥ | 10.0 | 10.0 | 10.0 | 10.0 | 11.0 | 11.0 | 11.0 | ||||||

Tensile strength after post cure(Mpa) 230°C,24H≥ | 12.0 | 12.0 | 12.0 | 12.0 | 13.0 | 13.0 | 13.0 | ||||||

Elongation at break after press cure ( Mpa) 170°C,10min≥ | 180 | 180 | 180 | 180 | 180 | 180 | 160 | ||||||

Elongation at break after post cure ( Mpa) 230°C,24H≥ | 160 | 160 | 160 | 160 | 160 | 160 | 150 | ||||||

200°C *70H Compressibility 20% Compression set (%) ≤ | 20 | 20 | 20 | 20 | 20 | 15 | 15 | ||||||

200°C, in No.3 jet fuel, weight increase after 24H (%) ≤ | 5 | 5 | 5 | 5 | 5 | 5 | 5 | ||||||

Water content (%) ≤ | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.1 | 0.1 | ||||||

FKM raw gum Terpolymer

Items | Items | T20 | T30 | T40 | T70 | T100 | |||||

Appearance | White or light-yellow sheet, no visible impurities | ||||||||||

Density (g/cm3) 23 °C | 1.84±0.02 | 1.84±0.02 | 1.84±0.02 | 1.84±0.02 | 1.84±0.02 | ||||||

Mooney viscosity (ML(1+10),121°C) | 20-30 | 30-40 | 40-60 | 60-90 | 90-120 | ||||||

Tensile strength after press cure(MPa)170°C,10min≥ | 9.0 | 9.0 | 9.0 | 10.0 | 10.0 | ||||||

Tensile strength after post cure(Mpa) 230°C,24H≥ | 11.0 | 11.0 | 11.0 | 13.0 | 13.0 | ||||||

Elongation at break after press cure ( Mpa)170°C,10min≥ | 180 | 180 | 180 | 180 | 180 | ||||||

Elongation at break after post cure ( Mpa)230°C,24H≥ | 160 | 160 | 160 | 160 | 160 | ||||||

200°C *70H Compressibility 20% Compression set (%) ≤ | 30 | 30 | 30 | 30 | 30 | ||||||

Oil resistivity | 180℃×24h 4109 bisphenol oil resistivity (%) ≤ | 6 | 6 | 6 | 6 | 6 | |||||

(200℃×24h) RP-3 oil resistivity (%) ≤ | 7 | 7 | 7 | 7 | 7 | ||||||

Water content (%) ≤ | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | ||||||

1. The experiment results above are based on the laboratory authorized by our company, which can be used for reference. Your test results may have some difference if the process of mixing, test equipment and test method are different.

2. Rubber compounds recipe: FKM:100g; AF: 2.0g; BPP: 0.5g; MgO: 3.0g; Ca(OH)2: 6.0g; N990: 30g. Press Cure 170℃@10min Post Cure 230℃@24hrs.

2. Rubber compounds recipe: FKM:100g; AF: 2.0g; BPP: 0.5g; MgO: 3.0g; Ca(OH)2: 6.0g; N990: 30g. Press Cure 170℃@10min Post Cure 230℃@24hrs.

Product Technical Property of FKM Precompound

FKM precompound Bisphenol Cure System

Bisphenol Cure Copolymer | ||||||||||||||||

Grade Name | Fluorine Content | Special Gravity | Mooney Viscosity | Hardness | Tensile Strength | Elongation at break | Compression Set | TR10 | ||||||||

% | g/cm3 | ML (1+10, 121℃) | Shore A | MPa | % | 200℃×22H* 25%(%) | ℃ | |||||||||

FR2101 | 66 | 1.82 | 15±5 | 77 | 13 | 200 | 20 | -17 | ||||||||

FR2161 | 66 | 1.82 | 15±5 | 77 | 13 | 230 | 20 | - 17 | ||||||||

FR2201 | 66 | 1.82 | 27±7 | 77 | 13 | 200 | 20 | -17 | ||||||||

FR2261 | 66 | 1.82 | 25±5 | 75 | 15 | 230 | 20 | - 17 | ||||||||

FR2361 | 66 | 1.82 | 35±5 | 75 | 14 | 280 | 20 | -17 | ||||||||

FR2401 | 66 | 1.82 | 40±5 | 77 | 16 | 210 | 19 | - 17 | ||||||||

FR2404 | 66 | 1.82 | 40±5 | 76 | 14 | 210 | 20 | -17 | ||||||||

FR2408S | 66 | 1.82 | 40±5 | 78 | 15 | 200 | 21 | - 17 | ||||||||

FR2501 | 66 | 1.82 | 50±5 | 76 | 16 | 200 | 19 | -17 | ||||||||

FR2561 | 66 | 1.82 | 50±5 | 76 | 16 | 230 | 19 | - 17 | ||||||||

FR2601 | 66 | 1.82 | 60±5 | 77 | 16 | 190 | 18 | -17 | ||||||||

FR2661 | 66 | 1.82 | 60±5 | 77 | 15 | 210 | 18 | - 17 | ||||||||

FR2901 | 66 | 1.82 | 80±10 | 77 | 16 | 190 | 17 | -17 | ||||||||

FR2961 | 66 | 1.82 | 80±10 | 76 | 15 | 200 | 17 | - 17 | ||||||||

Bisphenol Cure Terpolymer | ||||||||||||||||

FR3301 | 68 | 1.84 | 30±5 | 76 | 13 | 230 | 17 | - 17 | ||||||||

FR3301G | 69.5 | 1.87 | 30±5 | 79 | 12 | 220 | 30 | -15 | ||||||||

FR3361 | 68 | 1.85 | 30±5 | 75 | 11 | 320 | 19 | - 15 | ||||||||

FR3361G | 69.5 | 1.87 | 30±5 | 75 | 13 | 240 | 30 | -15 | ||||||||

FR3461 | 68 | 1.85 | 40±5 | 75 | 10 | 300 | 19 | - 15 | ||||||||

FR3401L | 65.5 | 1.81 | 40±5 | 75 | 12 | 180 | 14 | -19 | ||||||||

FR3501 | 68 | 1.84 | 50±5 | 77 | 13 | 210 | 19 | - 15 | ||||||||

FR3501G | 69.7 | 1.87 | 48±5 | 77 | 13 | 210 | 31 | -15 | ||||||||

FR3561 | 68 | 1.82 | 50±5 | 75 | 14 | 280 | 20 | - 15 | ||||||||

FR3661 | 68 | 1.85 | 60±5 | 77 | 14 | 200 | 18 | -15 | ||||||||

FR3701 | 68 | 1.84 | 70±5 | 78 | 14 | 200 | 18 | - 15 | ||||||||

FR3761 | 68 | 1.85 | 70±5 | 75 | 14 | 200 | 20 | -15 | ||||||||

FKM precompound Peroxide Cure System

Peroxide curable | ||||||||||||||||

Grade Name | Fluorine Content | Special Gravity | Mooney Viscosity | Hardness | Tensile Strength | Elongation at break | Compression Set | TR10 | ||||||||

% | g/cm3 | ML (1+10, 121℃) | Shore A | MPa | % | 200℃×22H* 25%(%) | ℃ | |||||||||

FR4201P | 70 | 1.9 | 25±5 | 75 | 19 | 210 | 20 | -7 | ||||||||

FR4301P | 70 | 1.9 | 35±5 | 75 | 19 | 230 | 20 | -7 | ||||||||

FR4302GLT | 67 | 1.85 | 30±5 | 66 | 18 | 190 | 20 | -24 | ||||||||

FR4361F | 70 | 1.9 | 37±3 | 75 | 20 | 190 | 20 | -5 | ||||||||

FR4357PLT | 66 | 1.84 | 50±5 | 69 | 17 | 190 | 20 | -24 | ||||||||

FR4357PFLT | 64 | 1.81 | 50±5 | 68 | 19 | 210 | 23 | -30 | ||||||||

FR4501P | 70 | 1.9 | 50±5 | 74 | 19 | 250 | 20 | -7 | ||||||||

Packing specification:

Packed in a polyethylene bag with a net content of 5kg per bag, and then placed in a cardboard box with a net content of 25kg per box.

Application

Packing & Shipping

About us

Jiangsu FreChem Co., Ltd.

FreChem is a professional research & development, manufacturer of high performance rubber compounds, special additives and fluorochemicals.

Starting from 2014, FreChem has now become one of the leading manufacturers of rubber compounds in China.

Thanks to our research & development capabilities, FreChem is able to provide highly qualified rubber compounds to global customers: Fluoroelastomer(FKM), Fluorosilicones(FVMQ),HNBR compounds, NBR compounds, EPDM compounds, SBR compounds, PVDF, PVDC, PTFE, PFA, FEP and so on.

FreChem expects to offer best solution as well as customization in order to meet customers’ special needs. The equipment and special know- how used in production control guarantee that our compounds respond to the customer requirement and provide high consistency standards.

Our vision is to become an excellent partners with customers and we will improve and focalize our skill on final application to develop compounds with high added value.

Starting from 2014, FreChem has now become one of the leading manufacturers of rubber compounds in China.

Thanks to our research & development capabilities, FreChem is able to provide highly qualified rubber compounds to global customers: Fluoroelastomer(FKM), Fluorosilicones(FVMQ),HNBR compounds, NBR compounds, EPDM compounds, SBR compounds, PVDF, PVDC, PTFE, PFA, FEP and so on.

FreChem expects to offer best solution as well as customization in order to meet customers’ special needs. The equipment and special know- how used in production control guarantee that our compounds respond to the customer requirement and provide high consistency standards.

Our vision is to become an excellent partners with customers and we will improve and focalize our skill on final application to develop compounds with high added value.

FAQ

We Recommend

New Arrivals

New products from manufacturers at wholesale prices