Customized nonstandard high quality alloy steel segment chain excavator sprocket

- Category: >>>

- Supplier: Luoyang Yujie Industry & Trade Co. Ltd.Luoyang Ltd.

Share on (1600911376939):

Product Overview

Description

We offer One-stop service From raw material organization to processing production and assembly .

professional engineer team to ensure the good quality.

High-precision CNC processing equipments.

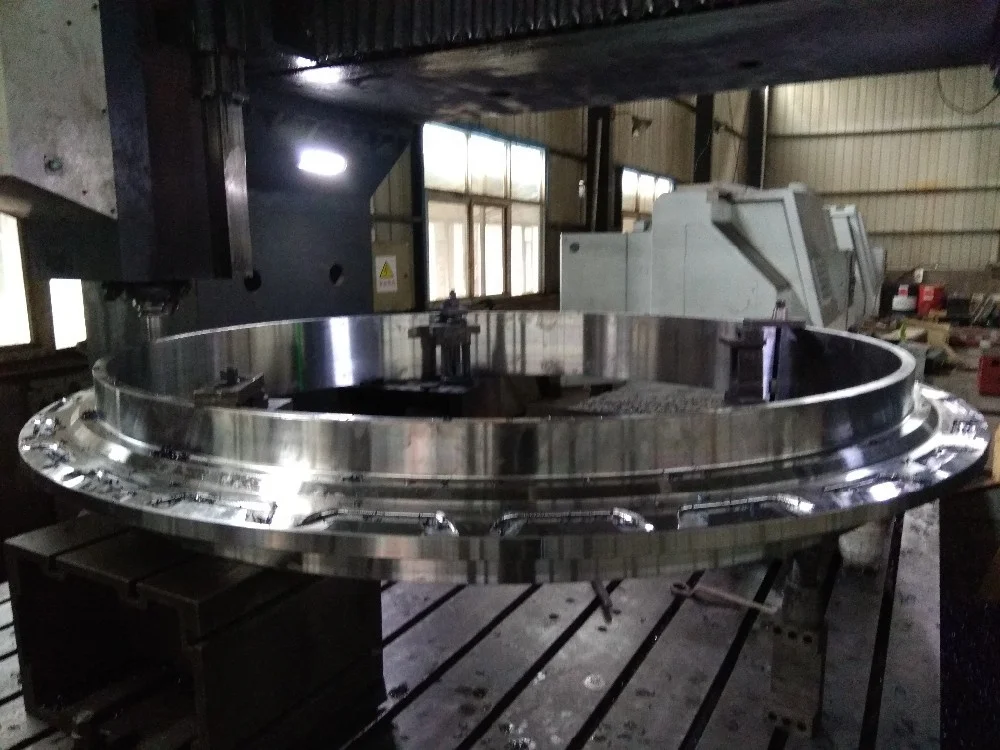

Customized nonstandard high quality alloy steel segment chain excavator sprocketThe excavator sprocket is an important component of the excavator's track system. It is typically made of high-strength alloy steel, with high hardness and wear resistance.The role of the excavator sprocket is to transmit power and bear the load during excavator operation. When the engine drives the hydraulic pump to generate hydraulic oil flow, the hydraulic oil is delivered to the hydraulic motor, which in turn drives the track system. The sprockets transmit power through the engagement of the chains, enabling the excavator to perform digging,loading, and other operations.Due to the large loads and frequent friction that the excavator sprockets endure, they need to have sufficient strength and wear resistance. Generally, the surface of the excavator sprocket undergoes a hardening treatment to increase its hardness and resistance to wear. Additionally, regular inspection and maintenance are required during use to ensure proper functioning and prolong the service life of the sprockets.In summary, the excavator sprocket plays a crucial role in the operation of the excavator. It carries the tasks of power transmission and load bearing, ensuring the normal operation of the excavator.

Product name | large diameter roller chain sprocket | ||||

Material | steel/alloy steel | ||||

Brand | YOJIE | ||||

Structure | Forging/casting | ||||

Process | CNC milling | ||||

Heat treatment | Quenching and tempering | ||||

Max.diameter | 750mm | ||||

Max.tolerance | ±0.05 | ||||

Surface treatment | black oxide/anti-rust oil | ||||

Weight | 500kg | ||||

Certificate | ISO | ||||

Specification | According to drawings | ||||

Package | Seaworthy packing | ||||

Delivery time | 45days | ||||

Certification | SGS | ||||

FORGING

UT check the material of the forging, the status after forging and check whether the forging has the defect of the lamination and the surface crack.

Measuring the size of the forging,calculation the processing allowance and accurate to estimate the cutting times in the turning process.

TURNING ON CNC VERTICAL LATHER

CNC MILLING

All the sprocket are processed by CNC milling machine,which can ensure the quality and precision of the sprocket.the accuracy is guaranteed within 0.05mm

FINISHED PRODUCT

The surface treatment of the large roller chain sprocket will be made according to customer's requirments.

INSPECTION

We have the advanced and perfect testing equipments,and we implement the quality system and metrology testing system strictly according to ISO9001.Every detail from the raw material to finished product are considered fastidiously and every producing process is supervised carefully by the inspector.

CNC gantry milling and boring machine,CNC machining center equipped with the fourth axis, CNC floor-type boring machine is equipped with the fourth axis and rotary worktable, it can realize five axis machining. The work piece is not limited by the size. It is suitable for machining large module and large size gear, boxes,and large non -standard parts.

Fax:0379-65163600

web:www.yogiemachinery.com

We Recommend

New Arrivals

New products from manufacturers at wholesale prices