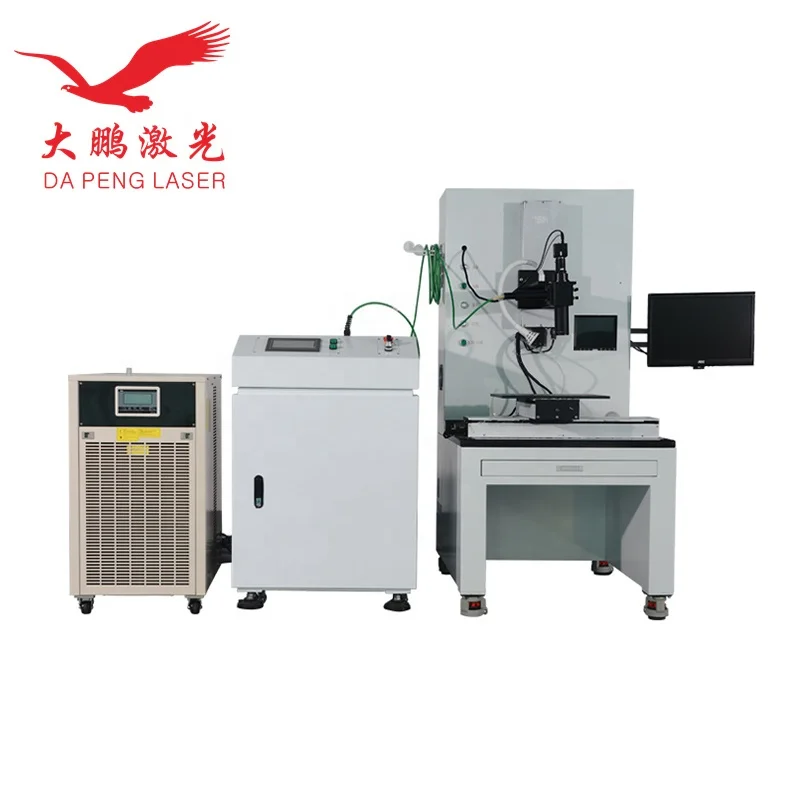

150W 300W 500W Fiber Laser Welding Equipment High Speed Galvanometer Laser Welding Machine

- Category: >>>

- Supplier: Shenzhen Dapeng Laser Technology Co. Ltd.Shenzhen Ltd.

Share on (1601005333736):

Product Overview

Description

150W 300W 500W Fiber Laser Welding Equipment High Speed Galvanometer Laser Welding Machine

Product Description

Specification

Model | DPH-150ZJ-FK-W | DPH-300ZJ-FK-W | DPH-500ZJ-FK-W |

Laser source type | Fiber source | Fiber source | Fiber source |

Laser Out Power | 150W | 300W | 500W |

Laser wavelength | 1064nm | 1064nm | 1064nm |

Focal spot diameter | 0.1-3mm | 0.1-3mm | 0.1-3mm |

Observation system | CCD camera | CCD camera | CCD camera |

Laser frequency | 1-50Hz | 1-50Hz | 1-50Hz |

Repeatability | ±0.01mm | ±0.01mm | ±0.01mm |

Machine operating temperature | 0~40℃ | 0~40℃ | 0~40℃ |

Electricity demand | 380V/50HZ/60A | 380V/50HZ/60A | 380V/50HZ/60A |

Cooling method | Water Chiller Hanli | Water Chiller Hanli | Water Chiller Hanli |

Continuous operating time | 24 hours | 24 hours | 24 hours |

Weight | 400kg | 400kg | 400kg |

Dimensions | 250*117*171cm | 250*117*171cm | 250*117*171cm |

Single Pulse Energy | 80J | 100J | 120J |

Features:

* 3C electrical metal parts welding* Mobile phone precision parts welding

* Precision stamping connector welding

* Precision medical equipment welding

* All kinds of metal spot welding, stack welding and so on

Laser welding system is the use of pulsed xenon lamp pumped Nd: YAG laser crystal output 1064nm wavelength laser,Real-time control of laser power negative feedback technique with arbitrary waveform ensures good stability and repeatability of laser power and its waveform in working condition,Product laser power from 200W to 600W covered a small, medium and high power system,Basically meet the needs of precision welding industry.Mainly for thin-walled materials, precision parts of the welding,Can achieve spot welding,butt welding, stack welding, sealing welding and so on,With high aspect ratio, small weld width, small heat affected zone, small deformation, fast welding speed, weld formation, beautiful, high weld quality, no stomata, precise control, small focusing spot,

high positioning accuracy,Optical fiber transmission easy to achieve automation.In the battery industry, IT industry, electronic devices, optical communications industry, the sensor industry, the hardware industry, auto parts industry, mold repair industry,jewelry welding industry, glasses industry, porcelain teeth, solar industry, electric industry has been widely used.

Product advantages:

Energy negative feedback laser welding machine works is the output of the laser to add an energy detection device used to detect the size of laser energy,And real-time feedback of the signal to the control side, compared with the theoretical set of energy to form a closed-loop control system to achieve accurate control of laser energy output purposes. Energy negative feedback technology can make the laser output energy has good repeatability, in simple terms, is to ensure that each output of laser energy stability,This can effectively improve product productivity. The output waveform can be arbitrarily set according to the welding material, shape and so on In the specific parts of the welding process, according to the work of the shape and material,Change the output waveform of laser energy,Can greatly improve the quality of welding,And even some of the traditional laser welding problems

can also be resolved by changing the output waveform of the laser. Laser can achieve multi-fiber output at the same time ,Compared with the traditional hard light output system, you can increase the degree of freedom of processing,Can be multi-beam at the same time processing and multi-station processing, for more sophisticated welding provides the conditions.

Click here to contact us for more information

Company Profile

Shenzhen Dapeng Laser Technology Co, Ltd. was established in 2011. It is a laser equipment high-tech enterprise that integrates R&D, manufacturing, sales and service. It is dedicated to laser process R&D, laser equipment design R&D, production, technical support, service and consulting.

Our company's main products include: laser cutting machine, laser welding machine, laser marking machine, industry-specific and automated laser equipment, etc, applied to electronics, IC chips, electrical appliances, lighting fixtures, jewelry, hardware tools, sanitary ware, instruments Instrumentation, automobile and motorcycle accessories, mobile phone communications components, molds, precision machinery, medical equipment, IT digital, metal housing, aviation components, garment leather, craft gifts, advertising decoration, models, cookware, kitchen utensils and other industries.

Dapeng laser product quality are stable and reliable, with a professional R & D team, while pursuing excellent quality, Dapeng laser also provides customers with timely, comfortable pre-sale, sales, after-sales service and excellent cost-effective products. Dapeng Laser has won the trust and praise of customers by implementing the business philosophy of "helping customers succeed, creating value models, and building industrial laser equipment industry to serve high-end brands". Customers are located throughout the country and overseas. In 2016, sold more than 5,000 laser equipment.

Our company has established a complete production and sales and after-sales service system, has production bases in Shenzhen, Wenzhou,Kunshan and Xiamen, has a large-scale laser cutting machine production base in Dongguan, and has offices in major domestic industrial cities and regions. There are equipment demonstrations, process proofing, sales and after-sales services, and resident technical service personnel, to provide customers with timely, comfortable pre-sales, sales, after-sales support and services.

Our company's main products include: laser cutting machine, laser welding machine, laser marking machine, industry-specific and automated laser equipment, etc, applied to electronics, IC chips, electrical appliances, lighting fixtures, jewelry, hardware tools, sanitary ware, instruments Instrumentation, automobile and motorcycle accessories, mobile phone communications components, molds, precision machinery, medical equipment, IT digital, metal housing, aviation components, garment leather, craft gifts, advertising decoration, models, cookware, kitchen utensils and other industries.

Dapeng laser product quality are stable and reliable, with a professional R & D team, while pursuing excellent quality, Dapeng laser also provides customers with timely, comfortable pre-sale, sales, after-sales service and excellent cost-effective products. Dapeng Laser has won the trust and praise of customers by implementing the business philosophy of "helping customers succeed, creating value models, and building industrial laser equipment industry to serve high-end brands". Customers are located throughout the country and overseas. In 2016, sold more than 5,000 laser equipment.

Our company has established a complete production and sales and after-sales service system, has production bases in Shenzhen, Wenzhou,Kunshan and Xiamen, has a large-scale laser cutting machine production base in Dongguan, and has offices in major domestic industrial cities and regions. There are equipment demonstrations, process proofing, sales and after-sales services, and resident technical service personnel, to provide customers with timely, comfortable pre-sales, sales, after-sales support and services.

Our Workshop

Why Choose US

Dapeng Laser has established a complete production and sales and after-sales service system, has production bases in Shenzhen, Wenzhou,Kunshan and Xiamen, has a large-scale laser cutting machine production base in Dongguan, and has offices in major domestic industrial cities and regions. There are equipment demonstrations, process proofing, sales and after-sales services, and resident technical service personnel, to provide customers with timely, comfortable pre-sales, sales, after-sales support and services.

Dapeng people know that quality and service are fundamental to the survival of the company. Innovation is the foundation for the long-tem development of the company. It helps customers create value and strives to build a well-known brand in the laser equipment industry.

Dapeng people know that quality and service are fundamental to the survival of the company. Innovation is the foundation for the long-tem development of the company. It helps customers create value and strives to build a well-known brand in the laser equipment industry.

Laser Welding Machine Team

Laser Cutting Machine Team

Oversea Marketing Team

Our Exhibition

Our Certificates

CE

ISO

Packing & Delivery

We support to ship via Sea, Railway,Air, Express(UPS, DHL, EMS, Swiss Post, HongKong Post, FedEx, TNT). You also can choose the shipping method you like if you prefer another courier.

FAQ:

Q1: How do I know which model is suitable for my product application?

You just need to tell us the following information then we can offer you a suitable solution? In addition, you can also send us the sample and we will arrange professional engineers for proofing evaluation

1) What is your product? material? thickness? required accuracy?

2) What is the current production process?

3) What is your desired budget and delivery time.

Q2: When I get this machine, but I don't know how to use it. What should I do?

We will send teaching video of both installation and operation, as well as the English manual. If you have further questions, we have engineers who can speak English can serve you on-line directly. And for some countries , like in India, Malaysia, Korea,Spain, we have local support team, more countries will be in the picture soon.

Q3: How can I do if the machine goes wrong?

We guarantee machine quality for 13 months, during this period, if spare parts of the machine were not man-made damaged, we can send the component to the customer in best delivery. Besides guarantee period, we still provide you free online services for life.If parts broken, you can order replacement parts from us.

Q4. Can you customized product according to different application?

Yes, Dapeng laser is very dedicated to combine with our current ability with the main leading supplier to offer you the customized application.

Q5:What if there are gaps in my product which need to weld?

For laser welding machines, we are usually equipped with automatic wire feeding system. For products with gaps, you can use wire feeding mechanism for wire filling welding

Q6. What is your normal lead time?

Generally standard machine, our lead time is 2-7 days after PO confirmed. Customized product need a little longer.

Q7. Will the package damaged during transportation?

Our package is considerate all the damage factors and make it to be safe, and our shipping agent have full experienced in safe tranportation. We have exported to 80 countries worldwide. So please don't worry, you will receive the parcel in good condition

Q8:Why should I choose DAPENG LASER compared with other companys?

We are factory with 453 employees, turnover reached 100 millions USD in 2021, ISO 9001 certificated and most products are CE/SGS approoved, can offer you a high-quality pre-sale, in-sale and after-sales solution.

You just need to tell us the following information then we can offer you a suitable solution? In addition, you can also send us the sample and we will arrange professional engineers for proofing evaluation

1) What is your product? material? thickness? required accuracy?

2) What is the current production process?

3) What is your desired budget and delivery time.

Q2: When I get this machine, but I don't know how to use it. What should I do?

We will send teaching video of both installation and operation, as well as the English manual. If you have further questions, we have engineers who can speak English can serve you on-line directly. And for some countries , like in India, Malaysia, Korea,Spain, we have local support team, more countries will be in the picture soon.

Q3: How can I do if the machine goes wrong?

We guarantee machine quality for 13 months, during this period, if spare parts of the machine were not man-made damaged, we can send the component to the customer in best delivery. Besides guarantee period, we still provide you free online services for life.If parts broken, you can order replacement parts from us.

Q4. Can you customized product according to different application?

Yes, Dapeng laser is very dedicated to combine with our current ability with the main leading supplier to offer you the customized application.

Q5:What if there are gaps in my product which need to weld?

For laser welding machines, we are usually equipped with automatic wire feeding system. For products with gaps, you can use wire feeding mechanism for wire filling welding

Q6. What is your normal lead time?

Generally standard machine, our lead time is 2-7 days after PO confirmed. Customized product need a little longer.

Q7. Will the package damaged during transportation?

Our package is considerate all the damage factors and make it to be safe, and our shipping agent have full experienced in safe tranportation. We have exported to 80 countries worldwide. So please don't worry, you will receive the parcel in good condition

Q8:Why should I choose DAPENG LASER compared with other companys?

We are factory with 453 employees, turnover reached 100 millions USD in 2021, ISO 9001 certificated and most products are CE/SGS approoved, can offer you a high-quality pre-sale, in-sale and after-sales solution.

*Send an inquiry and get product catalog manual!

We Recommend

Automatic concrete pile rebar cage welding machine

US $3000-$15000

High quality mini igbt mma arcwelders manufacturer

US $130.00-$140.00

New Arrivals

New products from manufacturers at wholesale prices