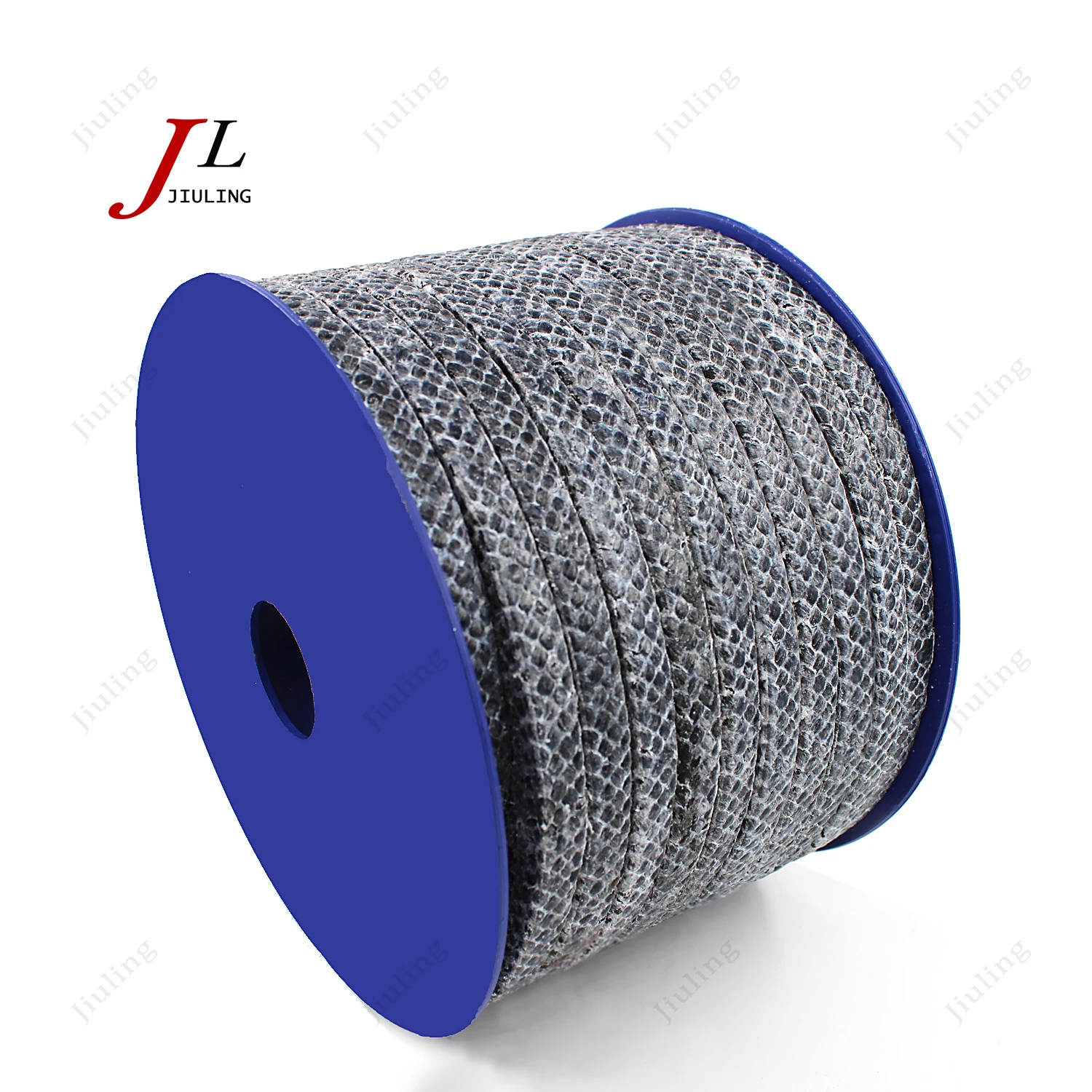

For Valve And Pump Packing Service High Quality Wholesale Activated Carbonized Fiber Packing With Ptfe Promotions Customized

- Category: >>>

- Supplier: Hejian Jiuling Trading Co. Ltd.

Share on (1601186942977):

Product Overview

Description

Specification

Place of Origin | Hebei, China |

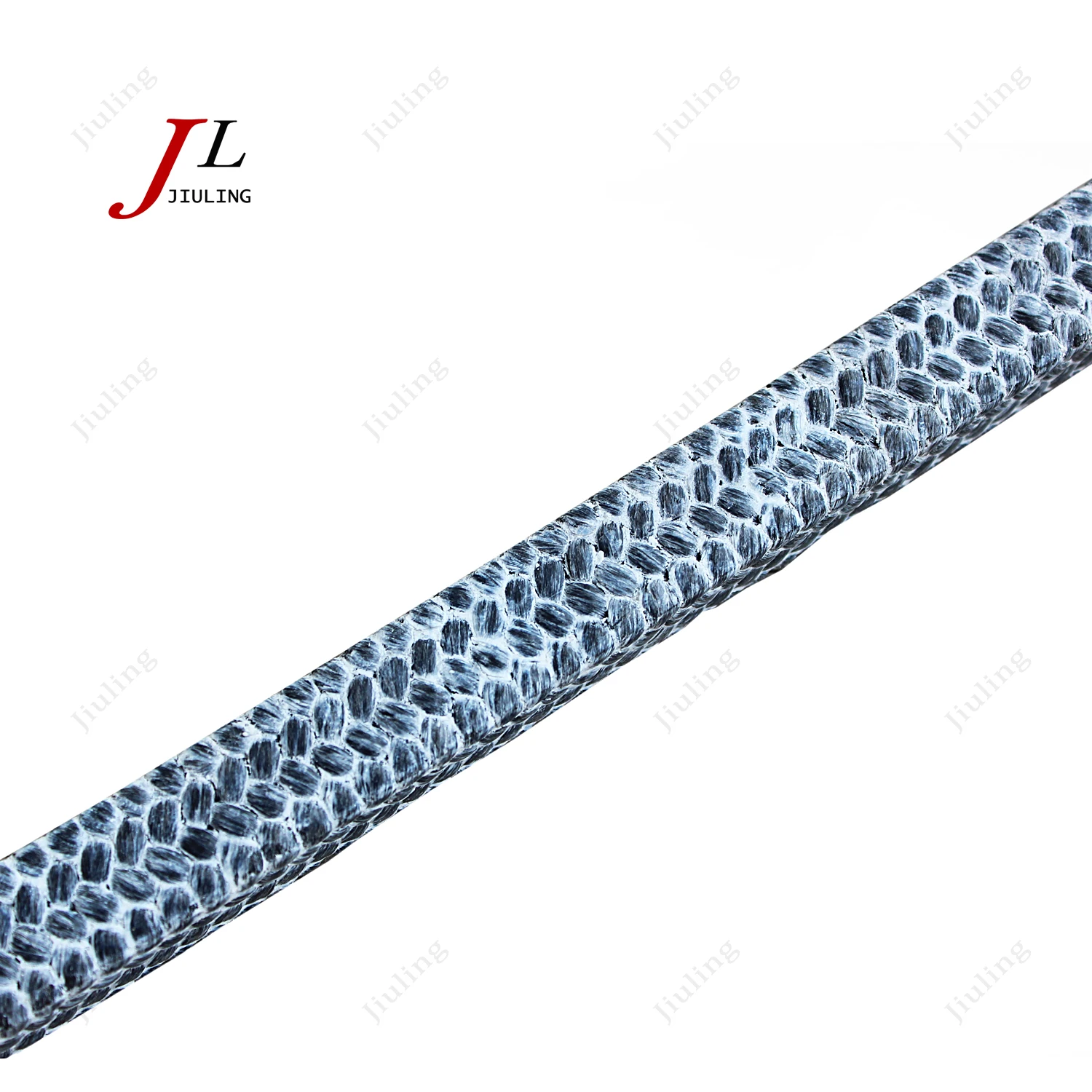

Product name | Carbon Packing |

Size | Customer Demand |

Application | Industry |

Color | WHITE AND BLACK |

Feature | High Temperature Resistance |

Material Type | Carbon |

MOQ | 10pcs |

Packing | Carton |

Sample | Freely |

Product Description

DESCRIPTION

Carbon Packing, chemical substances, mainly used in chemical, petroleum, chemical fiber, coal mining, power generation, metallurgy and other industries equipment.

TECHNICAL PERFORMANCE

__________________________________________________________________________________________________________________________________________

Temperature:-200℃-+350℃

Pressure:30MPa

Chemical tolerance:PH 1-14

Equipment: pumps, valves, reactors, flanges

Industry: Chemical, petroleum, chemical fiber, coal mining, power generation, metallurgy and other industry equipment.

Medium:acid, alkali and other corrosive liquids, organic solvents.

Carbon packing product specifications: 3 × 3mm-50 × 50mm. Special specifications or non-standard products can be formulated according to customer requirements.

TECHNICAL PARAMETERS

ITEM | Rotating | Reciprocating | Static |

Pressure Psi bar Kg/cm2 | 30 | 100 | 200 |

Shaft speed M/s | 30 | 2 |

Density g/cm3 | 1.8 |

Temperature °C | -200℃-+350℃ |

PH range | 1-14 |

COMPOSITION AND USE

Carbon packing is mainly composed of carbon fiber, the scientific name for carbon fibers is “Polypropylene-based carbon fiber”. A composite of carbon fibers and related matrix resins, such as epoxy, has several physical and mechanical properties comparable to those of metals. It is widely used in the fields of aerospace, aviation, chemical industry, electronics and sports equipment because of its high temperature resistance (& GT. 3000 â ° C) , ablation resistance, small Coefficient of thermal expansion, high specific strength and high specific volume. Carbon fiber is mainly composed of carbon elements of a special fiber, its carbon content varies with species, generally more than 90% . Carbon fiber has the characteristics of ordinary carbon materials, such as high temperature resistance, friction resistance, electrical conductivity, thermal conductivity and corrosion resistance, but different from ordinary carbon materials, its shape has remarkable anisotropy, soft, can be processed into a variety of fabrics, along the direction of fiber axis shows high strength. Carbon fiber has a low specific gravity and therefore a high specific strength. So carbon packing has good heat conductivity, wear resistance, chemical stability, and high mechanical strength, starting torque is small, it will not damage the pump shaft, long service life, is a variety of dynamic and static sealing of the ideal material. Carbon fiber packing suitable for acid and alkali corrosive liquids, organic solvents, used in petroleum, chemical industry, chemical fiber, coal mining, power generation, metallurgy and other industrial fields of flange, valve, reactor, pump sealing.

Company Profile

Hejian Jiuling international commercial trading company founded in 2024, is a foreign trade enterprise of import and export trade jointly founded by some manufacturers. The main projects are: building materials (including glass fiber mesh cloth, insulation nails, Angle steel, and various thermal insulation building materials). Sealing products (stainless steel sealing products, graphite sealing products, PTFE sealing products, etc.) and a variety of communication cables, hardware products, glass products and plastic products import and export business, at present, the company's trade scale continues to expand,our products are saled around the world,and with a good reputation to win the trust of domestic and foreign customers, we provide customers with a large number of high-quality and low prices products.Work with win-win cooperation as the goal. We sincerely hope: you and I go hand in hand to build a better cooperation!

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Selling Units: | Single item |

Single package size: | 100X100X100 cm |

Single gross weight: | 1.000 kg |

FAQ

1. who are we?

We are based in Hebei, China, start from 2020.Supported by several factories。

2. how can we guarantee quality?

Always final Inspection before shipment;

3.what can you buy from us?

Spiral Wound Gaskets,Ring Joint Gasket,Lens Gasket,Kammprofile Gasket,Graphite Gasketasbestos sheet, graphite sheet ,ptfe sheet

etc.

4.what is the moq?

50 pieces

5.Do you supply customization?

Yes, we offer customization as per your requirment.

6.Do you have a discount ?

Depend on amount

7. how soon you will deliver goods?

generally it is 3-7 days but depend on quantities.

8.Do you support packaging customization?

if you order large amount,we would like to offer.

We are based in Hebei, China, start from 2020.Supported by several factories。

2. how can we guarantee quality?

Always final Inspection before shipment;

3.what can you buy from us?

Spiral Wound Gaskets,Ring Joint Gasket,Lens Gasket,Kammprofile Gasket,Graphite Gasketasbestos sheet, graphite sheet ,ptfe sheet

etc.

4.what is the moq?

50 pieces

5.Do you supply customization?

Yes, we offer customization as per your requirment.

6.Do you have a discount ?

Depend on amount

7. how soon you will deliver goods?

generally it is 3-7 days but depend on quantities.

8.Do you support packaging customization?

if you order large amount,we would like to offer.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices