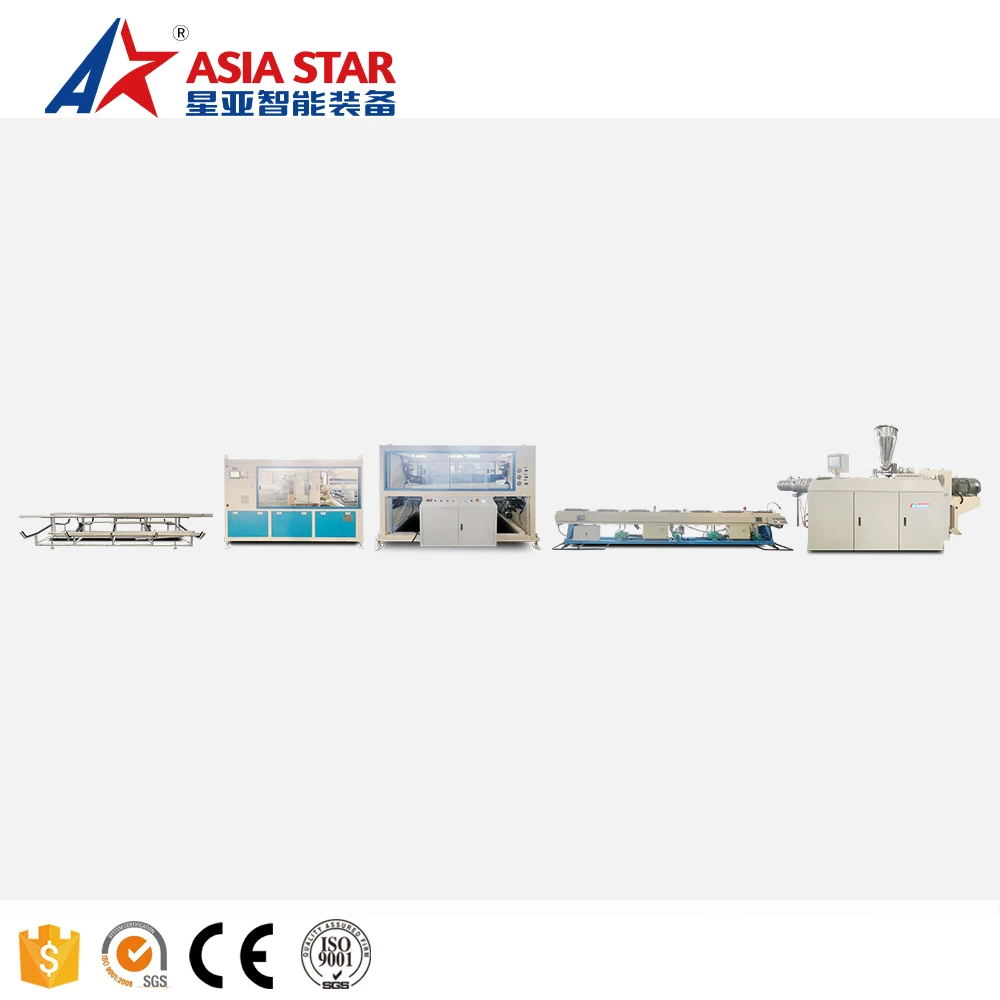

PP PE PVC pipe making machine price/Plastic flexible pipe extruder production line

- Category: >>>

- Supplier: Xingya (suzhou) Intelligent Equipment Manufacturing Co. Ltd.

Share on (1601199428764):

Product Overview

Description

Products Description

Main Technical Features

It is mainly used to produce all kinds of UPVC pipes for agricultural water supply and drainage, building water supply and drainage and cable laying, etc.

Saw cutter and planetary cutter for choice.

Changing some parts can also produce M-PVC pipe, C-PVC pipe, inner spiral wall pipe, inner hollow wall pipe, formed core pipe.

Conical twin screw extruder and parallel twin screw extruder for choice.

1. High lineal extrusion speed, big capacity and low power consumption, and achieved multi-layers co-extrusion with 1-5 layers.

2. The copper bush is more wear-resisting and prevent material leakage which can guarantee a stable running of extruder.

3. Material feed via spiral groove, efficient transmission and can effectively reduce back-pressure on extruder.

4. Unique design (barrier, shearing and mixing zone) guarantees a uniformed plasticizing effect, and can reduce the pressure on the screw which guarantees a high speed and stable output capacity.

5. High torque gear box has a smart figuration, compact construction, low noise, high carrying capacity, high transmission efficiency can assure long-time trouble-free operation;

6. PCA(pipe air cooling system) of die head largely increase the extrusion speed and decrease the cooling length of extrusion line, and improve quality of inner pipe surface;

7. Intelligent PLC controlling system with human-friendly interface make the operation easily and conveniently;

8. Chip-free cutter ensuing flat and smooth cutting surface of pipe.

Saw cutter and planetary cutter for choice.

Changing some parts can also produce M-PVC pipe, C-PVC pipe, inner spiral wall pipe, inner hollow wall pipe, formed core pipe.

Conical twin screw extruder and parallel twin screw extruder for choice.

Great advantages:

1. High lineal extrusion speed, big capacity and low power consumption, and achieved multi-layers co-extrusion with 1-5 layers.

2. The copper bush is more wear-resisting and prevent material leakage which can guarantee a stable running of extruder.

3. Material feed via spiral groove, efficient transmission and can effectively reduce back-pressure on extruder.

4. Unique design (barrier, shearing and mixing zone) guarantees a uniformed plasticizing effect, and can reduce the pressure on the screw which guarantees a high speed and stable output capacity.

5. High torque gear box has a smart figuration, compact construction, low noise, high carrying capacity, high transmission efficiency can assure long-time trouble-free operation;

6. PCA(pipe air cooling system) of die head largely increase the extrusion speed and decrease the cooling length of extrusion line, and improve quality of inner pipe surface;

7. Intelligent PLC controlling system with human-friendly interface make the operation easily and conveniently;

8. Chip-free cutter ensuing flat and smooth cutting surface of pipe.

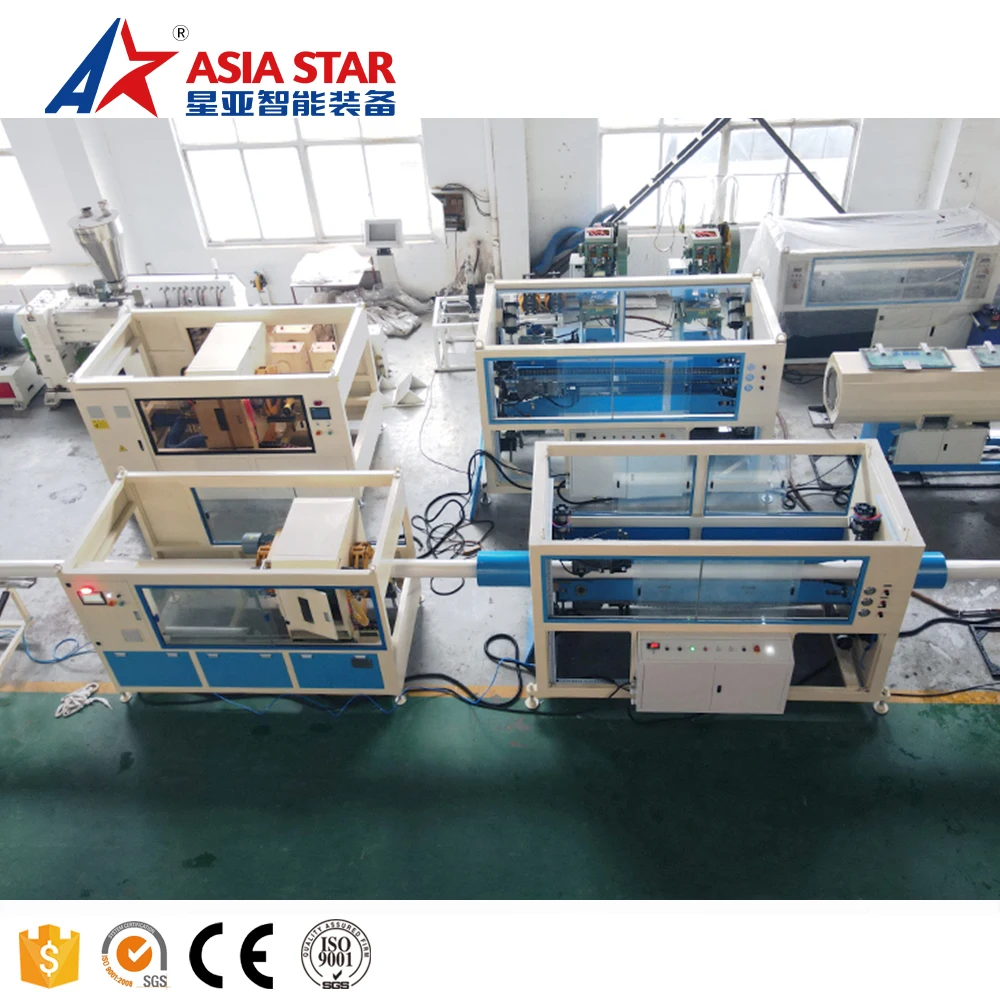

Nomally this line is composed by eight parts ,as follow:

The mixer can also be equiped by requirement .

The mixer can also be equiped by requirement .

Extruder | Specified screw design for better material plasticizing & mixing effect and lower cost formula; For high flling formula, screw of imported material with alloy sleeve treatment barrel can guarantee perfect solution. |

Die Head | Swallowtail split- flow support structure with the large compression ratio design can reduce joint line of the melt material and improve the pipe density and mechanical properties. |

Calibration Tank | High-efficiency two chamber and 5.6-12m long length design bring faster and more efficient cooling performance. |

Haul Off | Each traction belt can be inde pe ndently controlled, and mutual switch is to meet the needs of different diameters. |

Planetary Cutter | Automatic synchronisation with extrusion speed; planetary equipped with disk and milling cutter for cut and chamfering; universal pipe clamping device for easy operation. |

Coiler | It is mainly used for winding PE pipe, alumium pipe, corrugated pipe, and other some pipe or profles. . This pipe winding machine is highly automatic, and usually work with whole production line. |

Plastic Pipe Extrusion Line is mainly used in the production of agricultural drainage, water supply and cable conduit purposes. The unit consists of single extruder machine, mold, vacuum forming tank, multi-claw haul-off machine, planetary(chipless/non-dust cutter) cutting machine, stacker and so on. And the line can be equipped with Comptroller thickening instrument or computer ink-jet printer, etc. to achieve the production and manufacture of high-grade tubing.

Product Application

Company Profile

A-Star(Suzhou) Intelligent Equipment Manufacturing Co.,Ltd.

A-Star(Suzhou) Intelligent Equipment Manufacturing Co.,Ltd. is a modern factory, which engaged in the plastic extrusion machine and recycling machines' researching, manufacturing and saling. Our professional research teams, sales teams, rich experience and processing equipment will offer customers high quality machines and perfect after sales services.

Our major products including: single screw extruder, twin screw extruder, HDPE pipe production line, PP-R pipe production line, PVC pipe production line, plastic profile production line, plastic sheet production line, plastic mixing machine, waste plastic recycling machines, plastic pelletizing machines and relative auxiliary machines for the plastic machines. We will offer the customers the whole set of solution from extrusion to recycling and turn key projects. Our machines are highly praised by our customers for perfect perfomance, quick service, advantagetechnology.

Customer's satisfied is our target forever. We will offer detail solutions according to different customers detail conditions. Customers' expected products, services is what we are always insisting. High quality, Quick services, mutually beneficial will our promise to customers around the world.

Our major products including: single screw extruder, twin screw extruder, HDPE pipe production line, PP-R pipe production line, PVC pipe production line, plastic profile production line, plastic sheet production line, plastic mixing machine, waste plastic recycling machines, plastic pelletizing machines and relative auxiliary machines for the plastic machines. We will offer the customers the whole set of solution from extrusion to recycling and turn key projects. Our machines are highly praised by our customers for perfect perfomance, quick service, advantagetechnology.

Customer's satisfied is our target forever. We will offer detail solutions according to different customers detail conditions. Customers' expected products, services is what we are always insisting. High quality, Quick services, mutually beneficial will our promise to customers around the world.

Why Choose Us

1. A-Star(Suzhou) uses internationally renowned brand motors and appliances for customers to buy locally.

2. A-Star(Suzhou) can do plant planning for customers and maximize benefits with minimal cost.

3. A-Star(Suzhou) adopts special screw, long life, high plasticization.

4. A-Star(Suzhou) machinery high degree of automation, low energy consumption, high output.

5. A-Star(Suzhou) equipment design is reasonable, installation and disassembly is simple and convenient.

6. Once the customer has any problem in installing and operating the machinery, A-Star(Suzhou) will arrange corresponding technicians to provide online video guidance for the customer in the shortest time or go to the customer's factory to solve the problem if the government policy allows.

2. A-Star(Suzhou) can do plant planning for customers and maximize benefits with minimal cost.

3. A-Star(Suzhou) adopts special screw, long life, high plasticization.

4. A-Star(Suzhou) machinery high degree of automation, low energy consumption, high output.

5. A-Star(Suzhou) equipment design is reasonable, installation and disassembly is simple and convenient.

6. Once the customer has any problem in installing and operating the machinery, A-Star(Suzhou) will arrange corresponding technicians to provide online video guidance for the customer in the shortest time or go to the customer's factory to solve the problem if the government policy allows.

Certifications

Product packaging

FAQ

1. How many electric, water, air need for the machines?

A-Star: technical department supply the whole layout for workshop details.

2. Can I operate machine if don't have experienced engineers?

A-Star: (1) short-time engineers to customer company (5-15days)

(2) Year-time working as requirements

3. Any quality checking before shipment?

A-Star: 100% confirm, run and test machines before shipment with quality certificate.

4. How long is the guarantee?

A-Star: 12 months since the first day customer operates (except wear parts)

5. How can u help us when face some technical problem?

A-Star: 24 hours by e-mail, message, calling. If problems happens need engineer we will arrange the closest or agent in local country, or send Chinese Engineers to solve in 2 weeks.

6. Where can we get spare part?

A-Star: we choose International Brand that customer can find it in everywhere, such as Siemens, Omron, Delixi etc, or send parts by DHL, Fedex, TNT and other express.

A-Star: technical department supply the whole layout for workshop details.

2. Can I operate machine if don't have experienced engineers?

A-Star: (1) short-time engineers to customer company (5-15days)

(2) Year-time working as requirements

3. Any quality checking before shipment?

A-Star: 100% confirm, run and test machines before shipment with quality certificate.

4. How long is the guarantee?

A-Star: 12 months since the first day customer operates (except wear parts)

5. How can u help us when face some technical problem?

A-Star: 24 hours by e-mail, message, calling. If problems happens need engineer we will arrange the closest or agent in local country, or send Chinese Engineers to solve in 2 weeks.

6. Where can we get spare part?

A-Star: we choose International Brand that customer can find it in everywhere, such as Siemens, Omron, Delixi etc, or send parts by DHL, Fedex, TNT and other express.

Pre-sale service:

To help customers do market research, make project planning, and production line matched requirements analysis.

After-sale service:

To provide installation and test for the machine.

To provide formulas and technology of relevant products.

To provide information on chemical material manufactories.

To provide technical training for clients' employees.

To direct technology aspect of relevant use according to customers' requirements

To help customers do market research, make project planning, and production line matched requirements analysis.

After-sale service:

To provide installation and test for the machine.

To provide formulas and technology of relevant products.

To provide information on chemical material manufactories.

To provide technical training for clients' employees.

To direct technology aspect of relevant use according to customers' requirements

Main Products

We Recommend

New Arrivals

New products from manufacturers at wholesale prices