Reliability and Stability System YX250 WS Double Wave Soldering Machine for SMT Assembly Line

- Category: >>>

- Supplier: Wenzhou Yingxing Import&Export Co. Ltd.

Share on (1601228492369):

Product Overview

Description

Product Description

Feature

1.Open-type streamlined shell design, beautiful appearance, easy to clean.

2.The soldering furnace is made of 5.0mm thick alloy material. High-strength and high-hardness special aluminum alloy guide rail with long service life.

3.Touch screen + PLC control technology is adopted to ensure system reliability and stability.

4.The imported stepping motor spray device can be automatically adjusted with the width of the PCB, effectively saving welding aid.

5.Tin furnace wave peaks are controlled by an efficient and stable electronic frequency converter, which can independently control the wave height. The tin furnace can be automatically lifted in and out for easy maintenance. The backrest design prevents the machine from being hit by mistake.

6.Isolated device, flux fumes are discharged from the dedicated exhaust and recovery channels to meet environmental protection requirements.

7.Users can set the date, time, temperature control parameters, etc.

8.Equipped with cooling module and temperature compensation module, suitable for lead-free and multiple process requirements.

9.Imported 304 stainless steel heat-dissipating heating tube preheating device, which fully stimulates flux activity and obtains good welding effect the heat is directly radiated to the bottom of the PCB board, which generates heat quickly and has a long service life.

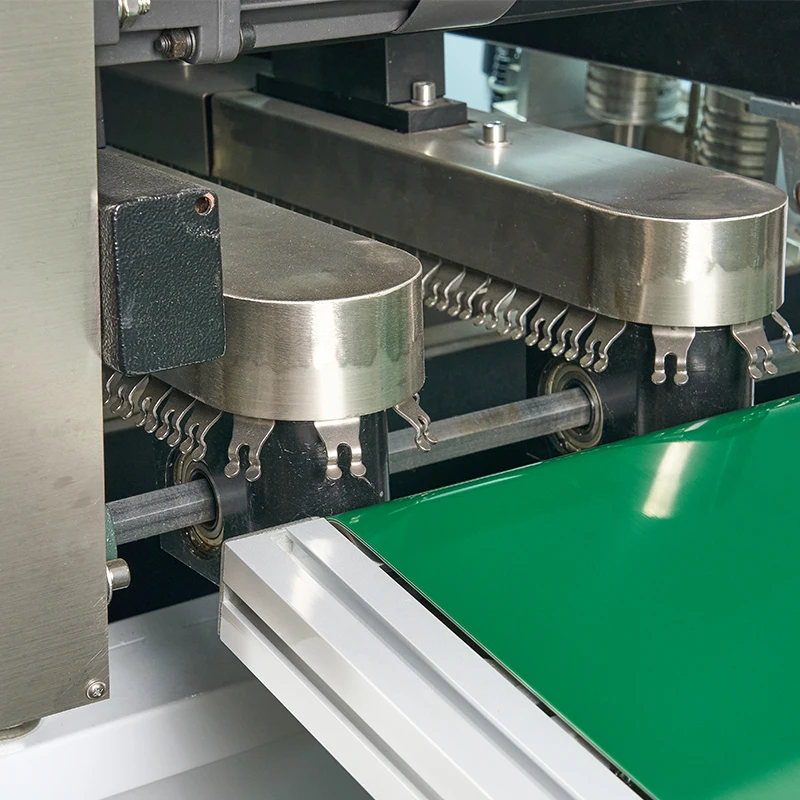

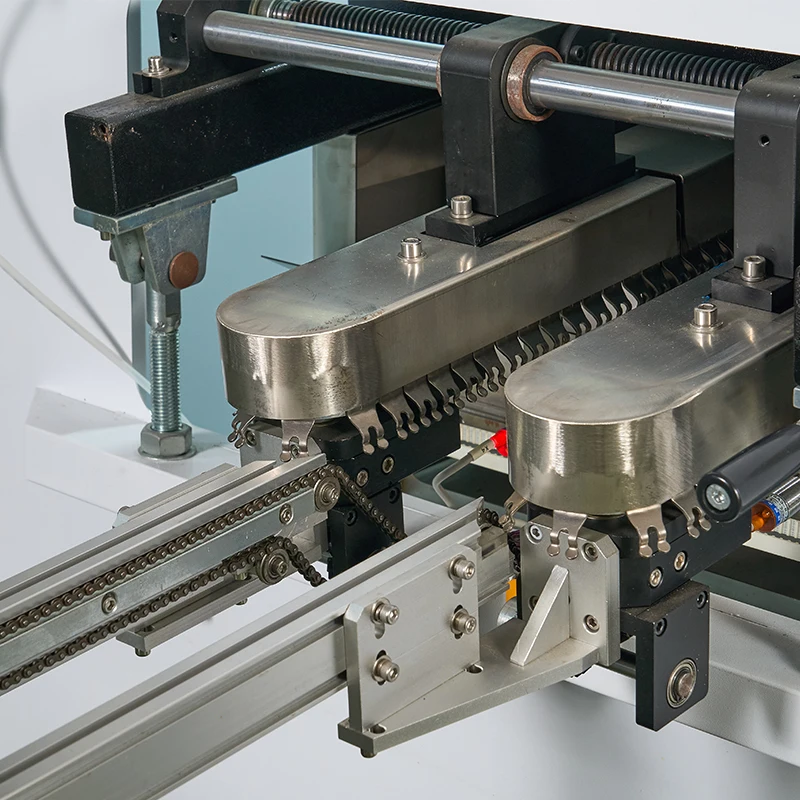

10.Patented die-casting chain claw, non-stick, never deformed, long life, stable and reliable transportation PCB.

11.The transparent observation window throughout the process facilitates observation of production and maintenance operations.

12.Tin furnace automatically lifts and enters and exits for easy adjustment. The backrest design prevents the machine from being damaged due to misoperation.

13.The transportation system adopts stepless electronic speed regulation, PID closed-loop control, and the transportation speed is stable.

14.Automatic wave passing through the board to minimize tin oxidation.

15.The temperature control system adopts PID closed-loop control mode, and the temperature control is stable and reliable.

16.With short circuit and over current protection system.

The YX250-WS software was developed by ourselves. The software is available in English. And our software will be updated, as soon as there is an update, the salesman will send new software to your mailbox.

The YX250-WS machine has one year warranty, lifetime maintenance. We have a professional after-sales team. As long as there is a problem with the machine within one year after purchase, we will repair it for free. If there is a need to replace the accessories, we will send them to your hands for free.(Generally we use TNT/DHL. 3-5 business days to your hands).

1.Open-type streamlined shell design, beautiful appearance, easy to clean.

2.The soldering furnace is made of 5.0mm thick alloy material. High-strength and high-hardness special aluminum alloy guide rail with long service life.

3.Touch screen + PLC control technology is adopted to ensure system reliability and stability.

4.The imported stepping motor spray device can be automatically adjusted with the width of the PCB, effectively saving welding aid.

5.Tin furnace wave peaks are controlled by an efficient and stable electronic frequency converter, which can independently control the wave height. The tin furnace can be automatically lifted in and out for easy maintenance. The backrest design prevents the machine from being hit by mistake.

6.Isolated device, flux fumes are discharged from the dedicated exhaust and recovery channels to meet environmental protection requirements.

7.Users can set the date, time, temperature control parameters, etc.

8.Equipped with cooling module and temperature compensation module, suitable for lead-free and multiple process requirements.

9.Imported 304 stainless steel heat-dissipating heating tube preheating device, which fully stimulates flux activity and obtains good welding effect the heat is directly radiated to the bottom of the PCB board, which generates heat quickly and has a long service life.

10.Patented die-casting chain claw, non-stick, never deformed, long life, stable and reliable transportation PCB.

11.The transparent observation window throughout the process facilitates observation of production and maintenance operations.

12.Tin furnace automatically lifts and enters and exits for easy adjustment. The backrest design prevents the machine from being damaged due to misoperation.

13.The transportation system adopts stepless electronic speed regulation, PID closed-loop control, and the transportation speed is stable.

14.Automatic wave passing through the board to minimize tin oxidation.

15.The temperature control system adopts PID closed-loop control mode, and the temperature control is stable and reliable.

16.With short circuit and over current protection system.

The YX250-WS software was developed by ourselves. The software is available in English. And our software will be updated, as soon as there is an update, the salesman will send new software to your mailbox.

The YX250-WS machine has one year warranty, lifetime maintenance. We have a professional after-sales team. As long as there is a problem with the machine within one year after purchase, we will repair it for free. If there is a need to replace the accessories, we will send them to your hands for free.(Generally we use TNT/DHL. 3-5 business days to your hands).

Items | Content |

Model | YX250-WS |

Size(mm) | L2300×M1200×H1650 |

Weight(kg) | 450KG |

Illumination | AC220V LED5W×1 |

Power Supply | AC380V 50Hz |

Total Starting Power | 11KW |

Total Working Power | About 2KW |

Spray Pressure | 3-5kgf/c+I34 |

Control Method | Touch screen+PLC control(Optional computer control) |

Transportation Power | AC220V 60W |

PCB Width | 0-250MM |

Angle Adjustment Device | Manual (electric optional) |

Transfer Speed | 0-1.8m/min |

Transmission Direction | Left→Right (optional direction) |

Transmission Method | Chain claw drive |

Preheating Total Power | 4KW |

Number of Preheating Sections | Two sections |

Preheating Range | Room temperature~250℃ |

Preheating Zone Length | 700mm |

Tin Furnace Temperature Control Range | Room temperature~300℃ |

Tin Furnace Capacity | 160KG-180KG |

Heating Power of Tin Furnace | 7kw |

Crest Motor | AC380V 0.18KW×2 |

Crest Height | 0-10mm |

Welding Angle | 3°~7° |

Lifting In and Out of Tin Furnace | Fully automatic one-button start |

Flux Capacity | 5.2L |

Timer Switch | Programmable settings |

Cooling Device | Cross-flow air cooling |

Cooling Air Volume | 1-1.5㎡/min |

Product Details

Company Information

Exhibition

Certifications

Product packaging

FAQ

Q:How is the training?

A:After buying our machines,your engineers can go to our company or it is so easy to operate the machine according the training video and user manual,the user manual will come with the machine together.

Q:Is it hard to use these machines?

A:After buying our machines,your engineers can go to our company or it is so easy to operate the machine according the training video and user manual,the user manual will come with the machine together.

Q:Is it hard to use these machines?

A:No,not hard at all.For our previous clients,at most 2 days is enough to learn to operate the machines.

Q:Does your machines have quality certificate?

A:All of our machines have passed CE certificate,ISO14001(BCC),ISO9001(IQNET) and have own patent.

Q:The Warranty of the machine?

A:One year,then the parts will be free for the buyer in the warranty.

Q:English version for these machines?

A:Yes

Q:Does your machines have quality certificate?

A:All of our machines have passed CE certificate,ISO14001(BCC),ISO9001(IQNET) and have own patent.

Q:The Warranty of the machine?

A:One year,then the parts will be free for the buyer in the warranty.

Q:English version for these machines?

A:Yes

We Recommend

Automatic concrete pile rebar cage welding machine

US $3000-$15000

High quality mini igbt mma arcwelders manufacturer

US $130.00-$140.00

New Arrivals

New products from manufacturers at wholesale prices