Resin SDC grinding wheel ring diamond cup grinding magnetic material semiconductor material

- Category: >>>

- Supplier: Xiamen Jianzuyang Trading Co. Ltd.

Share on (1601237086052):

Product Overview

Description

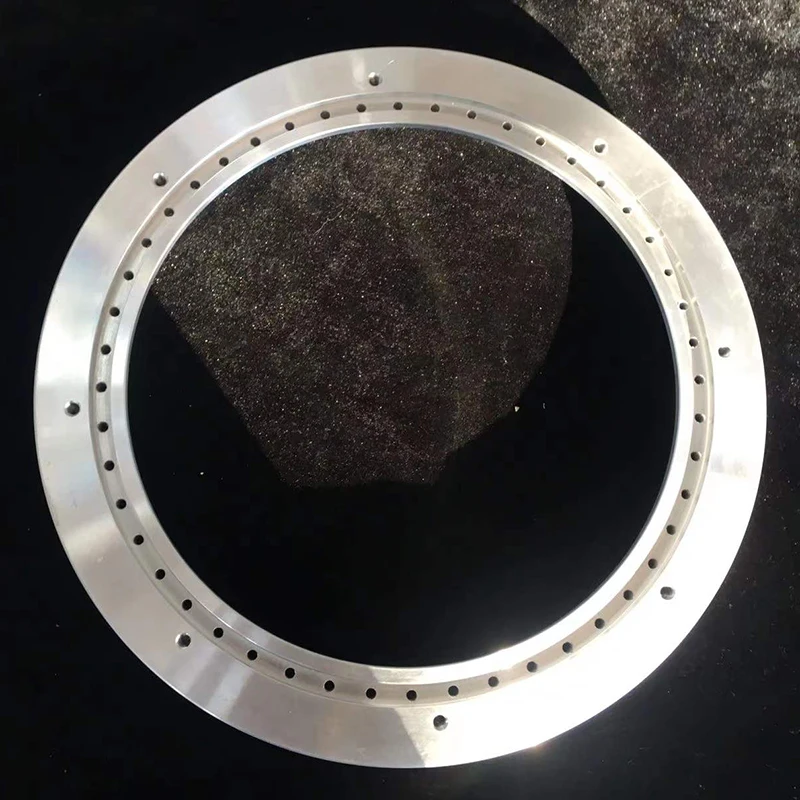

The hardness of the vitrified diamond grinding wheel is much greater than that of the resin bonded and metal sintered diamond grinding wheels. It can be cut freely, and the vitrified bonded grinding wheel has a longer service life. It can be self-dressed and polished, and is the choice of advanced grinding equipment.

In comparison, it greatly improves the grinding efficiency. The vitrified diamond grinding wheel is not easy to heat up and clog during the grinding process of the workpiece, and has high grinding efficiency. The vitrified bonded diamond grinding wheel has the advantages of high strength, easy to control the processing accuracy, small thermal expansion, strong heat resistance, and sharp cutting. Compared with the resin bonded diamond grinding wheel, it also reduces the life of the resin diamond grinding wheel during the grinding process. Customized according to the drawing

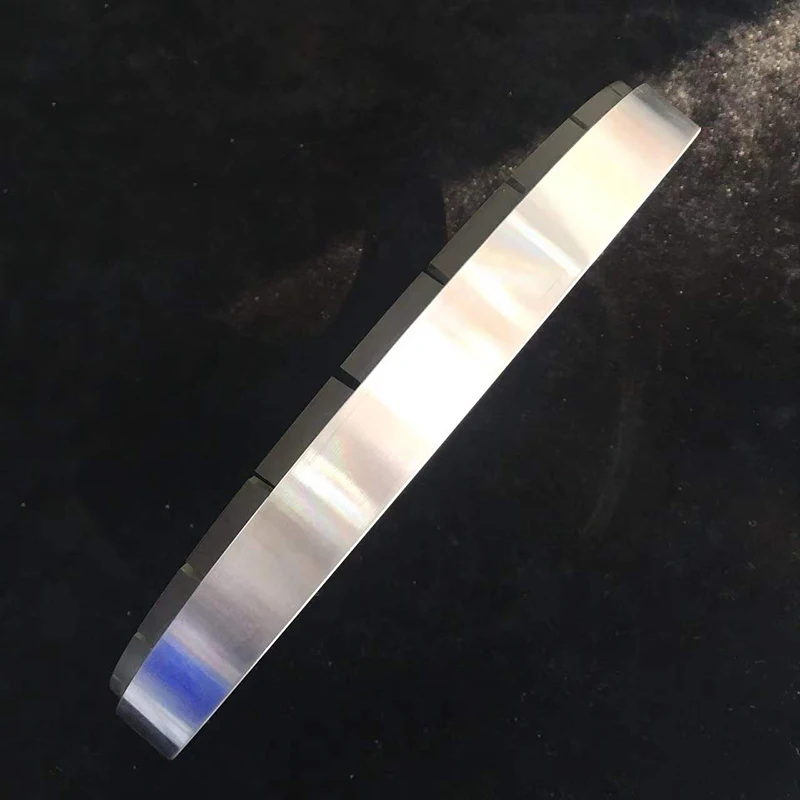

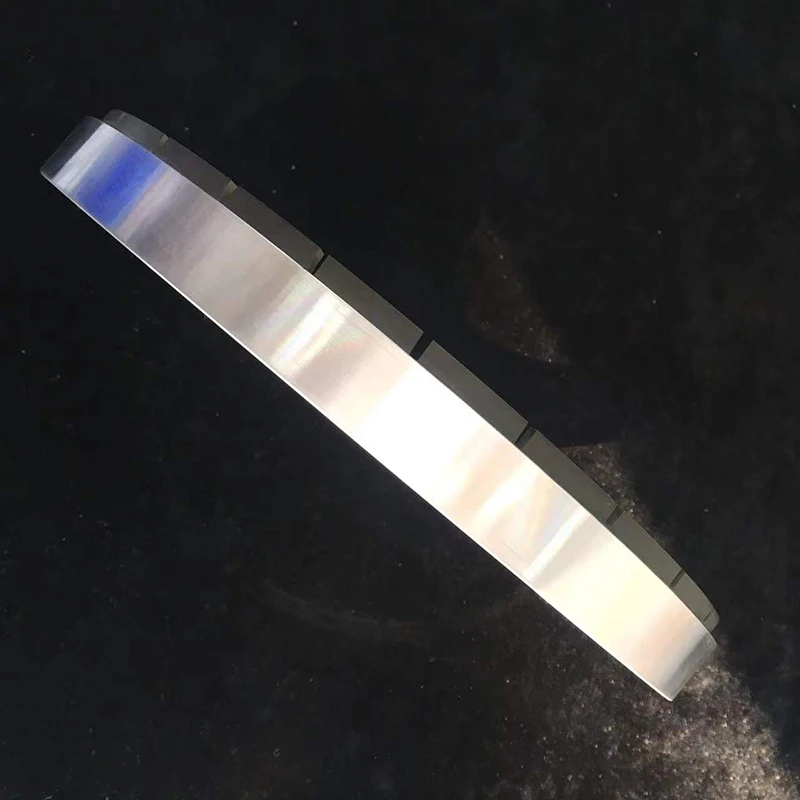

350mm size outer diameter resin diamond grinding wheel 5000 grit resin bonded diamond grinding wheel polishing wheel

Grind the diamond grinding wheel around the edge of the diamond wheel for reversible cutting tools

The peripheral frosted wheel is used for precision grinding of rotatable blades made of hard alloys, metal ceramics, and other materials, as well as for peripheral processing of PCD and PCBN cutting tools. Main features: Using heat-resistant resin and special additives as binders, it has good cutting, self sharpening, and retention properties, high grinding efficiency, good wear resistance, and can achieve optimization of feed speed and dressing frequency during the machining process. Application grinding machines: peripheral grinding machines such as Agton from Switzerland, Wada from Japan, Wante from Germany, Ivag from Switzerland, Jicheng from Tiantong, Haibao Precision Machinery from Beijing, and Chenggong Precision Machinery from Dongguan.

Superabrasive Tooling Diamond and CBN Wheels, 1A1, 3A1, 14A1 Side Grinding Wheels

Diamond/CBN Wheel for Flat Surface Grinding

Applications: Profile Grinding, Cut Off, Form Grinding,

O.D. Grinding, Dicing, Slicing

Bond Availability: Phenol, Polyimide, Hybrid, Electro-chemical

Available in: Diamond, CBN, CDX

Size Availability: 1" - 27"

*CDX Bond for Grinding Steel and Tungsten Carbide in combination

ITEM# BRAEMAR REF NUMBER | D O/A WHEEL DIAMETER | U ABRASIVE WIDTH | H ARBOR HOLE | T O/A WHEEL THICKNESS | J HUB DIAMETER | SPEC ABRASIVE HARDNESS & CONCENTRATION |

ED4A2000101213RS | 2.000" (51mm) | 0.156" (4mm) | 0.393" (10mm) | 0.281" (7.13mm) | 1.125" (28.57mm) | SD 120 R 100 B 0.187 DEPTH |

ED4A2000102013RS | 2.000" (51mm) | 0.156" (4mm) | 0.393" (10mm) | 0.281" (7.13mm) | 1.125" (28.57mm) | SD 200 R 100 B 0.187 DEPTH |

ED4A2000102213RS | 2.000" (51mm) | 0.156" (4mm) | 0.393" (10mm) | 0.281" (7.13mm) | 1.125" (28.57mm) | SD 220 R 100 B 0.187 DEPTH |

ED4A2000103213RS | 2.000" (51mm) | 0.156" (4mm) | 0.393" (10mm) | 0.281" (7.13mm) | 1.125" (28.57mm) | SD 320 R 100 B 0.187 DEPTH |

ED4A2000106013RS | 2.000" (51mm) | 0.156" (4mm) | 0.393" (10mm) | 0.281" (7.13mm) | 1.125" (28.57mm) | SD 600 R 100 B 0.187 DEPTH |

ED4A3000102212RS | 3.000" (76mm) | 0.156" (4mm) | 0.393" (10mm) | 0.393" (10.00mm) | 2.000" (50.00mm) | SD 220 R 100 B 0.250 DEPTH |

ED4A3000106012RS | 3.000" (76mm) | 0.156" (4mm) | 0.393" (10mm) | 0.393" (10.00mm) | 2.000" (50.00mm) | SD 600 R 100 B 0.250 DEPTH |

11V9 DIAMOND EWAG RESIN BOND WHEEL

| Address: | |||

| Contact Person: | |||

| Tel: | |||

| Bond | Vitrified; Resin; Metal; electroplated; Vacuum brazed; Other | ||

| Abrasive | Diamond ; CBN ; Diamond &CBN | ||

| *Grinding Condition | Cycle Time: | General Capacity | Longitudinal Movement: |

| Linear Speed: | Cross Movement: | ||

| Surface Quality (Ra.): | Vertical Movement: | ||

| *Grinding Wheel | Name: | Liquid | Water: |

| Size: | Oil: | ||

| Grit: | |||

| Annual Qty.: | Other: | ||

| Machine Tool | Brand: | Workpiece | Name: |

| Name: | Material: | ||

| Item No.: | Hardness: | ||

| Dressing Tool | Diamond Pen: | Wheels Currently Using | Supplier: |

| Rotary Dresser: | Price: | ||

| Dressing Depth: | Working Life: | ||

| Dressing Freq.: | Working Speed: | ||

| Processing Method | Flat Grinding: | Centerless Grinding: | |

| Outer Circle Grinding: | Cutting: | ||

| Inner Circle Grinding: | Other: | ||

| REMARK: | |||

We Recommend

New Arrivals

New products from manufacturers at wholesale prices