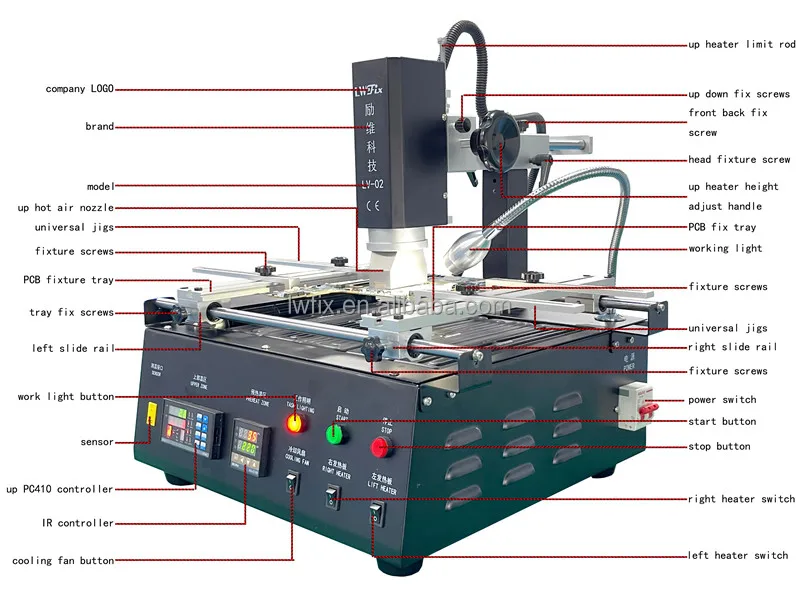

IR 3 Stage LV 02 IR8500 BGA Rework Station 4300W Power 220V Voltage New Welding Manipulator Repair Generator PCB Engine

- Category: >>>

- Supplier: Shenzhen Liwei Electronic Co. Ltd.Shenzhen Ltd.

Share on (1601245083912):

Product Overview

Description

Specification

Total power | 4300W |

Upper heater | 1200W |

Down heater | 3000W |

Power | (Single Phase) AC 220V±10 50Hz |

Location way | It can be placed on the support strip, and the upper heating head can be rotated back and forth to the specified heating position |

Temperature control | High precision K-type thermocouple (Ksensor) Closed Loop control, independent temperature measurement up and down |

Material | PC410 Temperature control instrument +C10 temperature control instrument |

Max PCB size | 420×390mm |

Min PCB size | 20×20mm |

Sensor port | 1pcs |

PCB thickness | 1-5mm |

Apply chip | 5-40mm |

Overall dimension | L420xW450xH4500mm |

Machine weight | Net weight 25kg |

Highlights of this LV-02 BGA Soldering Machine:

1. USB interface.

2. 2 temperature zones

3. With more heating panel,more uniform heating

4. Hot sale model, praised by many customers.

5. Low cost.

6. Technical support is always available

7. Original Factory, look for worldwide distributors

1. USB interface.

2. 2 temperature zones

3. With more heating panel,more uniform heating

4. Hot sale model, praised by many customers.

5. Low cost.

6. Technical support is always available

7. Original Factory, look for worldwide distributors

Product Description

Where this Hot Sale Low Cost LV-02 Micro Soldering Machine can be used for ?

1. For repairing Mobile phones

2. For repairing Notebooks/ Laptops/computers

3. For repairing game consoles, especially for XBOX360/PS3/WII

4. For repairing any other mainboards with size from 22x22mm to 420x390mm

5. For preheating chips or mainboards before soldering to improve rework efficiency.

1. For repairing Mobile phones

2. For repairing Notebooks/ Laptops/computers

3. For repairing game consoles, especially for XBOX360/PS3/WII

4. For repairing any other mainboards with size from 22x22mm to 420x390mm

5. For preheating chips or mainboards before soldering to improve rework efficiency.

1. Independent two-temperature zone temperature control system.

2. The upper temperature zone is heated by hot air, and the lower temperature zone is heated by IR infrared, which can be controlled independently.

3. The upper temperature zone and IR temperature zone are heated at the same time, and the principle of rapid cooling of cross-flow fan ensures that PCB will not be deformed during disassembly or welding;

4. The machine is simple and fast to operate, can directly place the PCB motherboard on the support bar, by moving the heating head before and after and rotating to any position on the board surface;

5. The upper temperature zone can be moved in any direction of manual rotation;

6. Using high-precision thermocouples to achieve precise temperature detection;

7. Equipped with a variety of different sizes of alloy hot air nozzle, 360° rotation, easy to replace, can be tailored according to actual requirements;

8. For large heat capacity PCB and other high temperature requirements, lead-free welding can be easily handled.

2. The upper temperature zone is heated by hot air, and the lower temperature zone is heated by IR infrared, which can be controlled independently.

3. The upper temperature zone and IR temperature zone are heated at the same time, and the principle of rapid cooling of cross-flow fan ensures that PCB will not be deformed during disassembly or welding;

4. The machine is simple and fast to operate, can directly place the PCB motherboard on the support bar, by moving the heating head before and after and rotating to any position on the board surface;

5. The upper temperature zone can be moved in any direction of manual rotation;

6. Using high-precision thermocouples to achieve precise temperature detection;

7. Equipped with a variety of different sizes of alloy hot air nozzle, 360° rotation, easy to replace, can be tailored according to actual requirements;

8. For large heat capacity PCB and other high temperature requirements, lead-free welding can be easily handled.

Company Profile

Packing & Delivery

FAQ

We Recommend

Automatic concrete pile rebar cage welding machine

US $3000-$15000

High quality mini igbt mma arcwelders manufacturer

US $130.00-$140.00

New Arrivals

New products from manufacturers at wholesale prices