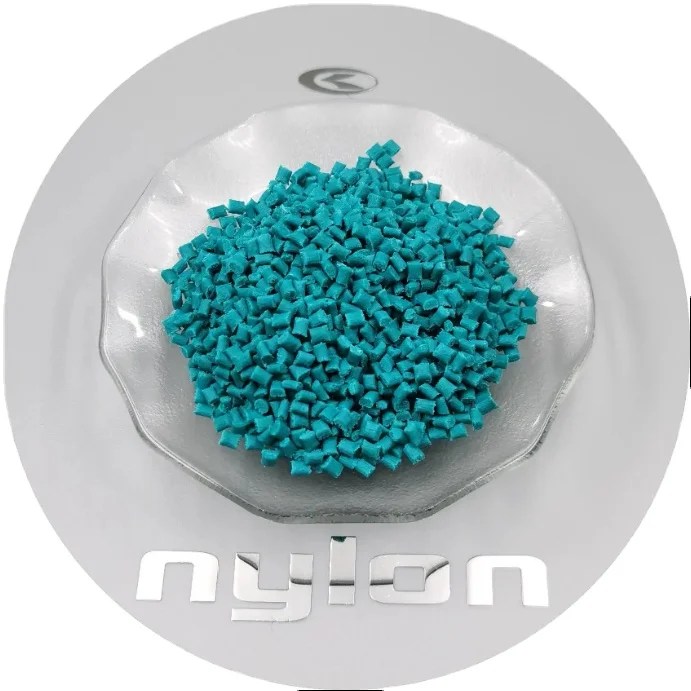

Nylon Resin PA66 1300G W3301 high performance engineering plastic with excellent mechanical strength, heat&wear resistance

- Category: >>>

- Supplier: Shenzhen Samtion Chemical Co. Ltd.

Share on (1601270099485):

Product Overview

Description

Products Description

Low viscosity, flame retardant with exceptional surface. Clear, tints and opaque colors. UV-stabilized.

.

"Polycarbonate" is made of bisphenol A, which is a polymer material of polycarbonate. It has excellent high transparency and heat resistance temperature, as well as the highest impact strength of thermal plasticity resin, and good formability

"Polycarbonate" is the best material of choice for replacing metal supplies for automobile components, business machines, home appliances,electronic parts, food appliances, medical equipment and communication equipment.

"Polycarbonate" is the best material of choice for replacing metal supplies for automobile components, business machines, home appliances,electronic parts, food appliances, medical equipment and communication equipment.

Product Paramenters

Property TYPICAL PROPERTIES (1) MECHANICAL | |||

Tensile Stress, yld, Type I, 50 mm/min | 62 | MPa | ASTM D 638 |

Tensile Stress, brk, Type I, 50 mm/min | 55 | MPa | ASTM D 638 |

Tensile Strain, yld, Type I, 50 mm/min | 7 | % | ASTM D 638 |

Tensile Strain, brk, Type I, 50 mm/min | 90 | % | ASTM D 638 |

Flexural Stress, yld, 1.3 mm/min, 50 mm span | 91 | MPa | ASTM D 790 |

Flexural Modulus, 1.3 mm/min, 50 mm span | 2240 | MPa | ASTM D 790 |

Hardness, Rockwell M | 70 | - | ASTM D 785 |

Hardness, Rockwell R | 118 | - | ASTM D 785 |

Taber Abrasion, CS-17, 1 kg | 10 | mg/1000cy | ASTM D 1044 |

IMPACT | Value | Unit | Standard |

Izod Impact, unnotched, 23°C | 3204 | J/m | ASTM D 4812 |

Izod Impact, notched, 23°C | 640 | J/m | ASTM D 256 |

Tensile Impact, Type "S" | 525 | kJ/m² | ASTM D 1822 |

Falling Dart Impact (D 3029), 23°C | 169 | J | ASTM D 3029 |

THERMAL | Value | Unit | Standard |

Vicat Softening Temp, Rate B/50 | 151 | °C | ASTM D 1525 |

HDT, 0.45 MPa, 6.4 mm, unannealed | 137 | °C | ASTM D 648 |

HDT, 1.82 MPa, 6.4 mm, unannealed | 132 | °C | ASTM D 648 |

CTE, -40°C to 95°C, flow | 6.84E-05 | 1/°C | ASTM E 831 |

Thermal Conductivity | 0.19 | W/m-°C | ASTM C 177 |

Relative Temp Index, Elec | 130 | °C | UL 746B |

Relative Temp Index, Mech w/impact | 120 | °C | UL 746B |

Relative Temp Index, Mech w/o impact | 130 | °C | UL 746B |

PHYSICAL | Value | Unit | Standard |

Specific Gravity | 1.21 | - | ASTM D 792 |

Specific Volume | 0.83 | cm³/g | ASTM D 792 |

Density | 1.217 | g/cm³ | ASTM D 792 |

Water Absorption, 24 hours | 0.15 | % | ASTM D 570 |

Water Absorption, equilibrium, 23C | 0.35 | % | ASTM D 570 |

Water Absorption, equilibrium, 100°C | 0.58 | % | ASTM D 570 |

Mold Shrinkage, flow, 3.2 mm | 0.5 - 0.7 | % | SABIC Method |

Melt Flow Rate, 300°C/1.2 kgf | 14.5 | g/10 min | ASTM D 1238 |

OPTICAL | Value | Unit | Standard |

Light Transmission | 85 | % | ASTM D 1003 |

Haze | 1 | % | ASTM D 1003 |

Refractive Index | 1.586 | - | ASTM D 542 |

ELECTRICAL | Value | Unit | Standard |

Volume Resistivity | >1.E+17 | Ohm-cm | ASTM D 257 |

Dielectric Strength, in air, 3.2 mm | 16.7 | kV/mm | ASTM D 149 |

Relative Permittivity, 50/60 Hz | 3.01 | - | ASTM D 150 |

Relative Permittivity, 1 MHz | 2.96 | - | ASTM D 150 |

Dissipation Factor, 50/60 Hz | 0.0009 | - | ASTM D 150 |

Dissipation Factor, 1 MHz | 0.01 | - | ASTM D 150 |

Arc Resistance, Tungsten {PLC} | 7 | PLC Code | ASTM D 495 |

Hot Wire Ignition {PLC) | 2 | PLC Code | UL 746A |

High Voltage Arc Track Rate {PLC} | 3 | PLC Code | UL 746A |

High Ampere Arc Ign, surface {PLC} | 2 | PLC Code | UL 746A |

Comparative Tracking Index (UL) {PLC} | 3 | PLC Code | UL 746A |

FLAME CHARACTERISTICS | Value | Unit | Standard |

UL Recognized, 94V-2 Flame Class Rating (3) | 1.47 | mm | UL 94 |

UL Recognized, 94V-0 Flame Class Rating (3) | 2.99 | mm | UL 94 |

UV-light, water exposure/immersion | F1 | - | UL 746C |

Parameter | ||||

Injection Molding | Value | Unit | ||

Drying Temperature | 120 | °C | ||

Drying Time | 3 - 4 | hrs | ||

Drying Time (Cumulative) | 48 | hrs | ||

Maximum Moisture Content | 0.02 | % | ||

Melt Temperature | 290 - 310 | °C | ||

Nozzle Temperature | 280 - 305 | °C | ||

Front - Zone 3 Temperature | 290 - 310 | °C | ||

Middle - Zone 2 Temperature | 275 - 300 | °C | ||

Rear - Zone 1 Temperature | 265 - 290 | °C | ||

Mold Temperature | 70 - 95 | °C | ||

Back Pressure | 0.3 - 0.7 | MPa | ||

Screw Speed | 40 - 70 | rpm | ||

Shot to Cylinder Size | 40 - 60 | % | ||

Vent Depth | 0.025 - 0.076 | mm | ||

Company Profile

The Shenzhen Samtion Chemical Co., Ltd

Focus on the export and production support of engineering plastics and special modified materials

15 Years Experience

We are a leading supplier of top end engineering plastics raw materials.

The company is formed by a group of senior teams engaged in the sales and production of engineering plastic materials for over 15 years.

The company is formed by a group of senior teams engaged in the sales and production of engineering plastic materials for over 15 years.

More Than 1,000 Customers

Up to now, we have provided

high-quality products and services to more than 1,000 customers in various industries, including: electronics and electrical appliances, medical, food, automotive electronics, optoelectronic communications, photovoltaic new energy, water treatment,transportation and other industries.

high-quality products and services to more than 1,000 customers in various industries, including: electronics and electrical appliances, medical, food, automotive electronics, optoelectronic communications, photovoltaic new energy, water treatment,transportation and other industries.

Quality Assurance

Every batch of our products is subject to strict quality inspection to ensure the original supply. All products have MSDS, ROHS, SGS, REACH,

EU, UL, COC / COA certificates!!

EU, UL, COC / COA certificates!!

Why Choose Us

Our Warehouse

With a strong sales network and strength, we have warehousing services in Guangzhou, Dongguan, Shenzhen free trade zone, Hong Kong and other four places (conventional product inventory exceeds 1000 tons). We can provide customers with rapid response, professional service and excellent products!

Quality Control

Our authentic products are guaranteed, with complete qualifications and superior supply capacity and price advantages.

Our Advantages

1.Professional focus:

Professional engineer service team with more than 15 years of experience; Provide a complete set of solutions and services from material sales, quality appraisal, mold design, molding and processing.

2.Perfect service:

We have served many high-quality and excellent domestic and foreign enterprises, and We understand the customers'

purchasing, product and service needs; From response time, price advantage, problem handling, etc., we provide comprehensive services based on customer needs in multiple dimensions.

purchasing, product and service needs; From response time, price advantage, problem handling, etc., we provide comprehensive services based on customer needs in multiple dimensions.

3. Inventory supporting:

Abundant inventory supporting resources, which are located in Guangzhou, Dongguan, Shenzhen free trade zone and Hong Kong. It has set up warehouses to stock goods, with a standing stock of more than 1000 tons, which can meet the timely spot purchase demand of customers and ensure the reliability and stability of the customer's material supply chain.

4.Logistics distribution:

We have long-term and stable logistics partners. According to the needs of customers, we formulate efficient istribution plans and deliver high-quality products to customers in time.

5. Speed advantage:

Professional engineer service team with more than 15 years of experience; Provide a complete set of solutions and services from material sales, quality appraisal, mold design, molding and processing.

6. Small batch type selection technical support

Accept small batch orders of 5kg at least; The rofessional engineer team can cooperate with customers to carry out material selection in the early stage of production, and provide corresponding material recommendations ccording to customer production and product requirements

7. Quality assurance:

Our products are all from well-known manufacturers. Each batch of materials has various inspection reports and certificates including original factory certificate, MSDS, ROHS, SGS, reach,, EU, UL, COC / COA, etc.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices