Compressed Wood Pallet Making Machine Sawdust Block Tray Nailer Making Machine European Pallet Production Line price for sale

- Category: >>>

- Supplier: Zhengzhou Leabon Machinery Equipment Co. Ltd.

Share on (1601281682350):

Product Overview

Description

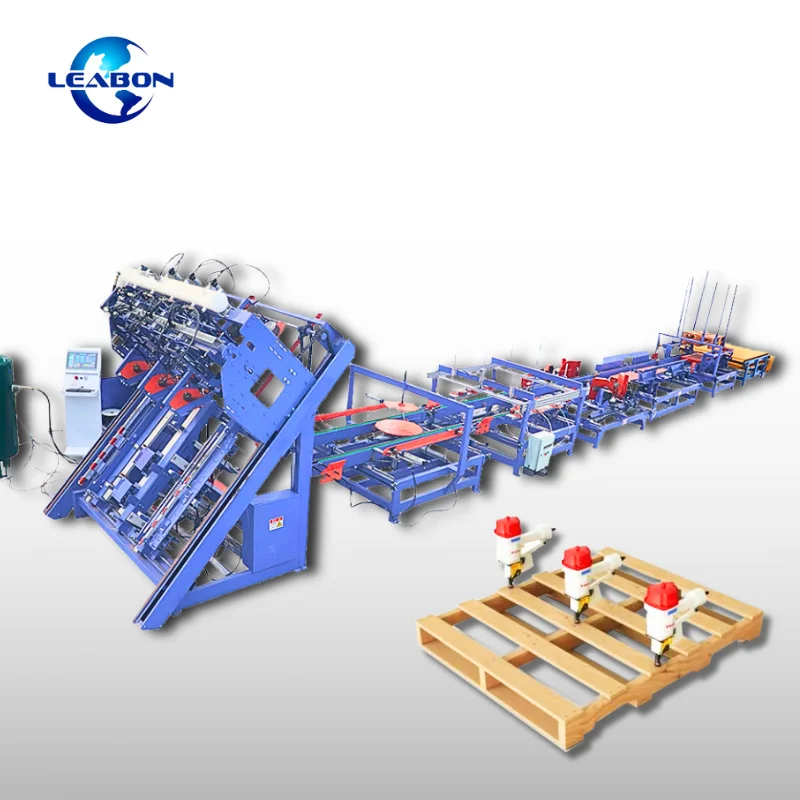

Compressed Wood Pallet Making Machine Sawdust Block Tray Nailer Making Machine European Pallet Production Line price for sale

1. Applicable tray type, European and American tray

2. Maximum size: 1300x1300x150mm (length x width x height)

3. Production efficiency: up to 60 per hour

4. Number of operators: 1

5. Use nailing tools: automatic air nail gun

6. Power consumption: less than 7.5kw

7. Position and type of nailing: each position can hit 2-4 nails

8. Mould: each tray with different size and structure requires two moulds

Leabon Wood Pallet Nailing Machine mainly used to nail the wood bars and block feet together,worker just wood bars on the support frame,then it can nail it automatic,then it can lift the finished wood pallet to stack machine,stack machine can stack the wood pallet layer by layer,of course you can choose wood pallet nailing machine with stack,you can aslo buy the wood pallet nailing machine.

Operation worker | 1person | Pallet size | Max 1300x1300mm |

Capacity | 60pcs/Hour | feeding materials mode | Manual |

Nailing mode | automatic | Stacking mode | Fully automatic (Cross stackable) |

Nail gun | CN80(max nail of 2.8x80mm) | Output mode | Fully automatic |

Power | 380v,50hz, 3Phase | Power | 7.5kw |

Nails | Large coil nail(3000pcs/coil) | Cover area | 2.5x14m (Width x Length) |

A. Special molds, the pallets produced are standard

B. Flip and tilt the workbench, the worker can easily unwind, no need to move too much, the other one can complete the unwinding;

C. Simultaneous nailing on both sides reduces the time and space required for turning and conveying

D. Manual feeding, easy to choose suitable materials and board surface

E. Using one-to-one mold, it is convenient and quick to change different trays, each replacement takes about half an hour

F. Use servo motor to accurately control each nailing position.

G. For each different pallet, the chip of the machine can record the nailing position, enter it once, save it to form a menu, and use it next time, directly read the corresponding menu without repeated settings.

H. Pallets of similar structure and materials can be designed with adjustable molds to save investment

I. The nails used by the nail gun are common to manual nailing, which is convenient for users to purchase

J. Nail guns are common to manual nail gun accessories for easy maintenance

K. Using a nail gun, the thickness of the plate is within ±3mm, and all nails can be nailed normally without heading.

L. It can realize the cross palletizing of the positive and negative buckles of the tray.

M. covers a small area, about 14x2.5 meters.

The final pallet display! Can be customized according to your requirements!

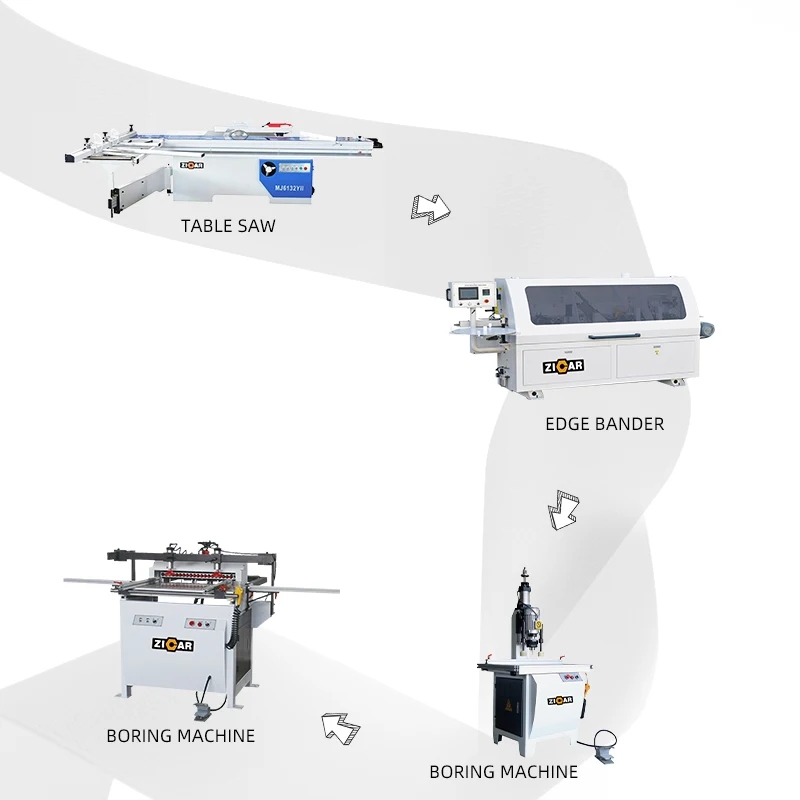

Sawdust Block Making Line:

Automatic Pallet Nailing Line:

Pre-sale service:

1-Reply customer's email or call customer back in 3 hours if missed any calls.

2-Design the best processes and programs according to customer's usage and requirement.

3-24 hours online, answer customer's questions patiently.

On purchase service :

1-Commissioning the machines before shipment carefully.

2-Train the customer's technician,And provide operation video and matters needing attention

3-Arrange customs declaration, sea shipping, insurance, etc.

After-sales service :

1-Out machines' warranty period is 12 month, We will provided spare parts, But will need customer bear the delivery cost.We charge cost price and delivery cost after the warranty period.

2-Provide the solution of the installation or use problem within 3 working hours.

3-Engineers able to install and train the operators overseas.

We sincerely hope to cooperate with more and more customers from the domestic and overseas for mutual development.

We Recommend

competitive price hot pur laminating line for solid wood/MDF/veneer with film

New Arrivals

New products from manufacturers at wholesale prices