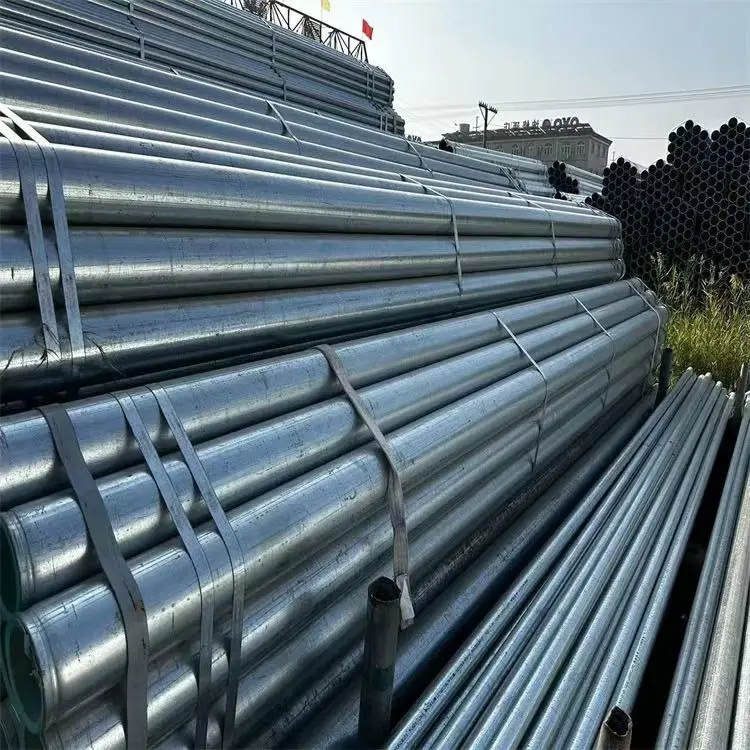

Welded stainless steel pipe welding tube tubos de acero inoxidable ASTM A312 201 304 metal tube customized piping

- Category: >>>

- Supplier: Shandong Zhile Metal Products Co. Ltd.Shandong Ltd.

Share on (1601290480957):

Product Overview

Description

Product Description

Seamless pipe processing

Seamless pipe is the strongest among all pipes type as it has a homogeneous structure throughout the pipe length.

In the Mandrel Mill pipe manufacturing process, the steel billet is heated to a high temperature in the rotary furnace. A cylindrical hollow is produced with the help of a rotary piercer and a set of roller arrangements that keeps the piercer at the center of the billet. The outside diameter of the piercer is approximately that of the inside diameter of the finished pipe. With the help of a secondary roller arrangement, outside diameter and thickness are achieved.

Welded pipe processing

Welded Pipes are manufactured from Plate or continuous Coil or strips. A welded pipe can be manufactured in large sizes without any upper restriction. There are different welding methods used to weld the pipe.

* ERW- Electric Resistance Welding

* EFW- Electric Fusion Welding

* HFW- High-frequency welding

* SAW- Submerged Arc Welding (Long seam & Spiral Seam)

* ERW- Electric Resistance Welding

* EFW- Electric Fusion Welding

* HFW- High-frequency welding

* SAW- Submerged Arc Welding (Long seam & Spiral Seam)

Company Information

We are specialized in processing stainless steel products like pipes, plates,coils, angle bar, rod and so on. Besides, cooper, brass, aluminum, titanium and other alloy steel like Inconel alloy are all in our range. Due to our commitment, high quality ,competitive price and good after-sales service, we have build long-term and stable relationships both in domestic and oversea market.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices