Heavy Duty Automatic Pipe Welding Machine Smooth Running Versatile Automatic Pipe Welding Machine

- Category: >>>

- Supplier: Qingdao Yuehongbo Welding And Cutting Equipment Co. Ltd.Qingdao Ltd.

Share on (1601313757093):

Product Overview

Description

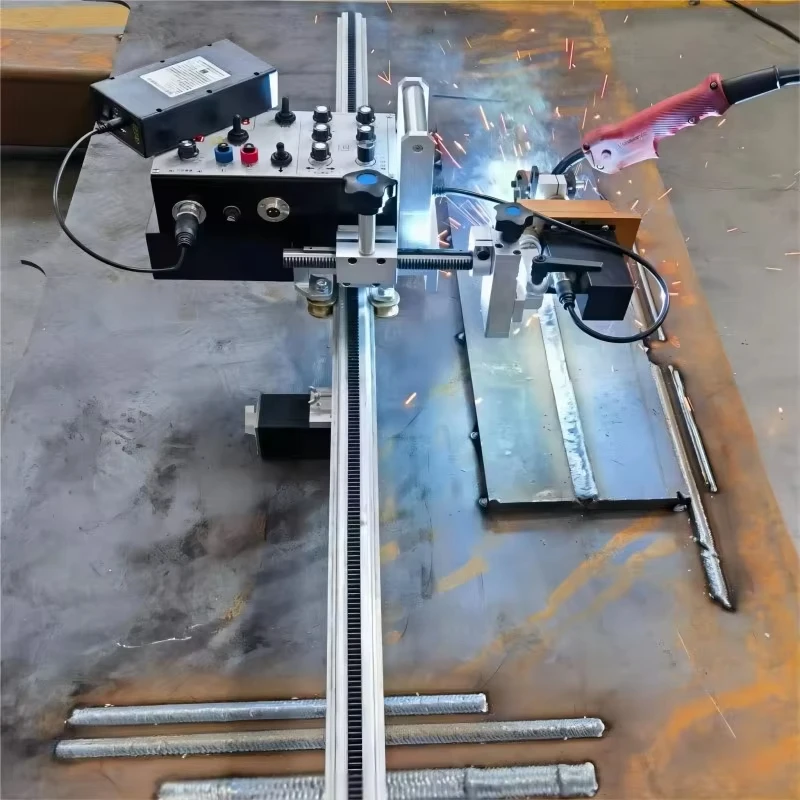

KA-HE8

KA-HE8 is a welding equipment that uses a rack and pinion drive to travel on track. It is widely used in horizontal butt welding and vertical butt welding, and is especially suitable for medium and thick plate welding. By adjusting the position and angle of the welding gun, fillet welding, horizontal welding and overhead welding can also be performed. The trolley body, swing device and control panel are integrated into one, and can be welded while walking on the track. The track is attracted to the workpiece with powerful magnets, making it easy to install and disassemble.

1. Ka-He8 can achieve various locations such as vertical welding, horizontal welding and horizontal welding.

2. There is a straight line swing function. Various swing parameters such as swing mode, swinging amplitude, swing speed, swing center position and left and right stay time can be adjusted.

3. Use a digital to display the speed of the car.

4. In order to prevent the emergence of the bite and insufficient welding when welding, the left and right swing stop time adjustment function is set.

2. There is a straight line swing function. Various swing parameters such as swing mode, swinging amplitude, swing speed, swing center position and left and right stay time can be adjusted.

3. Use a digital to display the speed of the car.

4. In order to prevent the emergence of the bite and insufficient welding when welding, the left and right swing stop time adjustment function is set.

6. Have a fast return function.

7. Standard configuration provides a 1.5m long track. The rail miniaturization light movement is convenient, and it can also be connected to extend the use.

Project | Content | Notes | ||||

Car | Power supply | AC 220V, 50/60Hz AC 220V, 50/60Hz | ||||

Dimensions | 500 x355 x 243 450 x320 x 240 | W×L×H L× W × H | ||||

Weight | 10.6Kg 10.6Kg | |||||

Driving Mode | Rack drive | |||||

Walking speed | 0~1040mm/min 0 ~ 1040mm/min | Digital display | ||||

Gun adjustment range | 上下 Up and down | ± 20mm ± 20mm | ||||

Before and after | ± 20mm ± 20mm | |||||

Operation angle | 360° 360 ° | |||||

To angle | ± 90 ° ± 90 ° | |||||

Track | Installation Type | Detachable magnets | ||||

Dimensions | 42×29.3 ×1500 42 × 29.3 × 1500 | W×H×L W × H × L | ||||

Material | Aluminum | |||||

Weight | 6Kg 6Kg | Including magnet | ||||

Swing Parameter | Swing Parameter | Swing mode | ||||

Swing speed | 0-1520mm/min 0-1520mm/min | |||||

Swings | ± 20mm ± 20mm | |||||

Residence time of about | 0-2s 0-2s | |||||

Center | ± 5mm ± 5mm | |||||

1.DC motor: the power device for the car to move. Use AC220V power supply.

2.Guide rail: Aluminum rigid guide rail, standard configuration is 1.5m, can be docked and extended for use.

3.Guide rail mounting magnet: rail fixing device. It can generate 60Kg of suction force and can be firmly adsorbed on the workpiece. Comes with a release handle for easy disassembly and movement of the track.

4.Control panel: The control center of the car, from which all actions are controlled.

5.Installation handle: trolley track wheel clutch device. During installation, twist this handle to drive the track wheel to open. After the track wheel is stuck on the track, loosen the handle and the track wheel will automatically lock. When the handle is in the half-clutch state, the quick return function can be achieved.

6. XY slider: adjustment mechanism for welding gun position. The adjustment range in the X direction is ±20mm, and the adjustment range in the Y direction is ±20mm.

7.Swing motor: the driving device of the oscillator. It uses a high-precision DC motor with a power of 6W.

8.Welding gun clamp: the clamping device of the welding gun. The angle of the welding gun can be adjusted with an adjustment range of ±90°.

2.Guide rail: Aluminum rigid guide rail, standard configuration is 1.5m, can be docked and extended for use.

3.Guide rail mounting magnet: rail fixing device. It can generate 60Kg of suction force and can be firmly adsorbed on the workpiece. Comes with a release handle for easy disassembly and movement of the track.

4.Control panel: The control center of the car, from which all actions are controlled.

5.Installation handle: trolley track wheel clutch device. During installation, twist this handle to drive the track wheel to open. After the track wheel is stuck on the track, loosen the handle and the track wheel will automatically lock. When the handle is in the half-clutch state, the quick return function can be achieved.

6. XY slider: adjustment mechanism for welding gun position. The adjustment range in the X direction is ±20mm, and the adjustment range in the Y direction is ±20mm.

7.Swing motor: the driving device of the oscillator. It uses a high-precision DC motor with a power of 6W.

8.Welding gun clamp: the clamping device of the welding gun. The angle of the welding gun can be adjusted with an adjustment range of ±90°.

(1) "Welding/non-welding" switch: When the "welding" position is selected, the machine enters the welding preparation state and presses the "start" switch to start welding. When the "non-welding" position is selected, press the "start" switch and the trolley will only move but will not weld.

(2)OFF: When the switch is turned on, the trolley starts to move. If the "welding/non-welding" selection switch is in the "welding" position, welding starts; if the "welding/non-welding" selection switch is in the "non-welding" position, only the trolley moves but no welding is performed.

(3) ON : If you press the stop switch during the trips of the car, all the actions will stop.

(4) Up Down: You can choose to walk up or down.

(5) speed: The speed value is displayed in digital, the maximum walking speed is 1040mm/min, and the digital display value is 999.

(6) Swing speed adjustment knob: Turn clockwise to increase the swing speed, the maximum value is 1520mm/min. It is indicated by scale, the maximum scale is 10.

(7) Swing range: Turn clockwise to increase the swing amplitude, the maximum value is 30mm. It is indicated by scale, the maximum scale is 10.

(8) LEFT Stop time adjustment knob: The adjustment range is 0 ~ 2S, and clockwise increases.

(9) Right stop time adjustment knob : The range is 0 ~ 2s, and clockwise increases.

(10) CENTER moving: When rotating clockwise, the center will move to the right, and the center will move to the left when the clockwise rotation counterclockwise, and the maximum range of movement is ± 5mm. The maximum scale value is represented by scale value.

(11) swing choice: Use this knob to select the swing mode. There are five types of swing mode of the car.

(2)OFF: When the switch is turned on, the trolley starts to move. If the "welding/non-welding" selection switch is in the "welding" position, welding starts; if the "welding/non-welding" selection switch is in the "non-welding" position, only the trolley moves but no welding is performed.

(3) ON : If you press the stop switch during the trips of the car, all the actions will stop.

(4) Up Down: You can choose to walk up or down.

(5) speed: The speed value is displayed in digital, the maximum walking speed is 1040mm/min, and the digital display value is 999.

(6) Swing speed adjustment knob: Turn clockwise to increase the swing speed, the maximum value is 1520mm/min. It is indicated by scale, the maximum scale is 10.

(7) Swing range: Turn clockwise to increase the swing amplitude, the maximum value is 30mm. It is indicated by scale, the maximum scale is 10.

(8) LEFT Stop time adjustment knob: The adjustment range is 0 ~ 2S, and clockwise increases.

(9) Right stop time adjustment knob : The range is 0 ~ 2s, and clockwise increases.

(10) CENTER moving: When rotating clockwise, the center will move to the right, and the center will move to the left when the clockwise rotation counterclockwise, and the maximum range of movement is ± 5mm. The maximum scale value is represented by scale value.

(11) swing choice: Use this knob to select the swing mode. There are five types of swing mode of the car.

Qingdao Yuehongbo Welding and Cutting Equipment Co., Ltd. was established in 2012. It is an entity company integrating design, research and development, manufacturing and sales.

The company's products include automatic welding trolleys, special trolleys for all-position pipeline welding, weld seam laser trackers, visual tracking systems, welding oscillators, special equipment for corrugated board welding, special machines for straight seam plate welding, etc. The products are mainly aimed at large and medium-sized welding companies, and the scope of use includes: steel structure, shipbuilding, bridge, automobile industry and other manufacturing companies. It can realize different welding processes such as horizontal butt joint, right angle joint, vertical butt joint, vertical angle joint, circumferential pipe welding, horizontal butt joint, horizontal angle welding, etc.

The products are sold in more than 20 domestic autonomous regions in China, and exported to more than 20 countries and regions such as Southeast Asia, Europe and the United States. Comprehensive economic indicators (including productivity, sales, and profits) have been leading in the welding equipment industry.

We will follow the purpose of creating value for customers and providing opportunities for employees, and in the corporate style of "pursuing transcendence, harmonious development" and "unity and cooperation, integrity and truthfulness".

We look forward to cooperating with friends at home and abroad to create a brilliant future.

Q1:Is your company a trading one or a factory?

A:Factory and trade (we have our own factory site.)

Q2:How many years have you been producing welding equipment?

A:We have been in this industry for more than 10 years

Q3:Which payment terms are you accepted?

A:T/T

Q4:When to deliver the goods after the order is placed?

A:It depends on the quantity of the products. Generally we can arrange shipment after 15 to 20 days.

Q5. Does your company accept customization?

We have excellent design team, and we accept OEM.

Q6.:What's the shipping method?

A: International express and sea transportation,Depends on the customer

Q7: Can you send me the video to show how the machine works?

A: Certainly, we have made video of every machine.

Q8: How can I know your machine works well?

A: Before delivery, we shall test the machine working condition for you.And we warmly welcome you to China for inspection.

A:Factory and trade (we have our own factory site.)

Q2:How many years have you been producing welding equipment?

A:We have been in this industry for more than 10 years

Q3:Which payment terms are you accepted?

A:T/T

Q4:When to deliver the goods after the order is placed?

A:It depends on the quantity of the products. Generally we can arrange shipment after 15 to 20 days.

Q5. Does your company accept customization?

We have excellent design team, and we accept OEM.

Q6.:What's the shipping method?

A: International express and sea transportation,Depends on the customer

Q7: Can you send me the video to show how the machine works?

A: Certainly, we have made video of every machine.

Q8: How can I know your machine works well?

A: Before delivery, we shall test the machine working condition for you.And we warmly welcome you to China for inspection.

We Recommend

Automatic concrete pile rebar cage welding machine

US $3000-$15000

High quality mini igbt mma arcwelders manufacturer

US $130.00-$140.00

New Arrivals

New products from manufacturers at wholesale prices