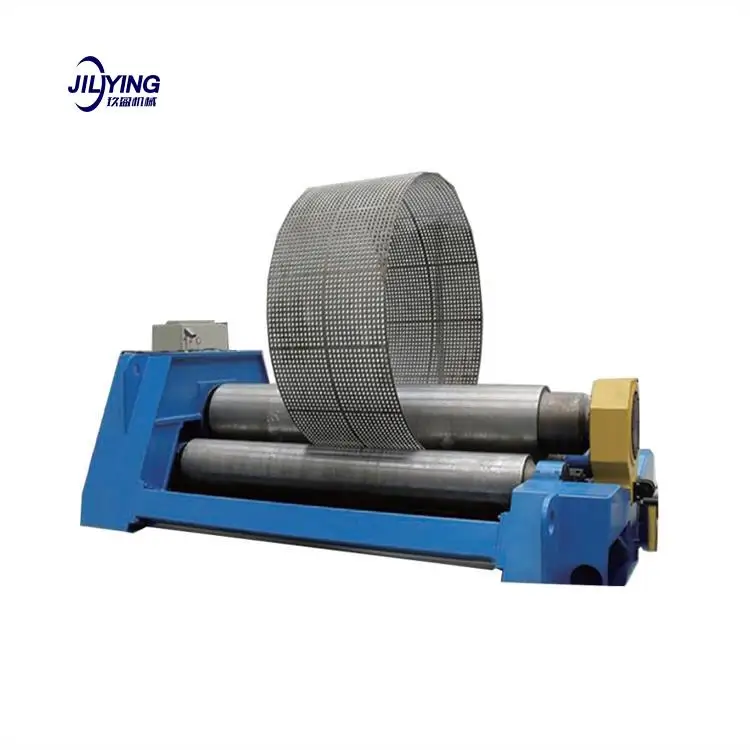

W12NC 70x4000mm metal plate 4 roller rolling machine steel pipe iron sheet rolling machine

- Category: >>>

- Supplier: Anhui Colgar Machinery Manufacturing Co. Ltd.Anhui Ltd.

Share on (1601356464108):

Product Overview

Description

Products Description

The Features:

1, High Precision end Pre-bending

The straight enge length can be set freely, the upper roller press to pre-bend NC Control, high productivity.Parameters are

controlled by NC, easy for operation, improve the productivity greatly

2, Good accuracy

The upper roller is like a drum, the lower rollers assorted with it through support rollers. Bend continuously, can roll ideal

products from thin to thick plates widely

3, Safety

The lower rollers are fixed, the upper roller move vertically and horizontally. The job does not work with the working rollers.

Complete structure, simple foundation, convenient movement. The machines has unitary basement, does not need earth bolts, has simple foundation

The straight enge length can be set freely, the upper roller press to pre-bend NC Control, high productivity.Parameters are

controlled by NC, easy for operation, improve the productivity greatly

2, Good accuracy

The upper roller is like a drum, the lower rollers assorted with it through support rollers. Bend continuously, can roll ideal

products from thin to thick plates widely

3, Safety

The lower rollers are fixed, the upper roller move vertically and horizontally. The job does not work with the working rollers.

Complete structure, simple foundation, convenient movement. The machines has unitary basement, does not need earth bolts, has simple foundation

Main parts:

1.Working rollers: cast steel ingot(chemical composition analysis):check performance-forging roughcast-forging annealing-UT flaw-roughing(chemical tests)-heat treatment(hardening and tempering)-UT flaw-semi finishing-finishing-MT.

2..Large forigings: cylinder body, gear, gear shaft forging roughcast-surface imspection-roughing-UT flaw-UT flwa detector hear treatmenat-finishing semi-finishing-MT.

3.Welding structure: racks, chassis, wheel box plate into the factory(chemical compositon analysis, mechanical

test)-pretreatment-for sheet metal cutting-welding-seam UT or RT flaw-annealing treatment-roughing-finishing-vibration

destressing-hot blasting-finishing 5-4 major parts of the manufacturing process.

2..Large forigings: cylinder body, gear, gear shaft forging roughcast-surface imspection-roughing-UT flaw-UT flwa detector hear treatmenat-finishing semi-finishing-MT.

3.Welding structure: racks, chassis, wheel box plate into the factory(chemical compositon analysis, mechanical

test)-pretreatment-for sheet metal cutting-welding-seam UT or RT flaw-annealing treatment-roughing-finishing-vibration

destressing-hot blasting-finishing 5-4 major parts of the manufacturing process.

The Technical Parameters | ||||||||

Discoloration due to quenching treatment of fuselage and rollers, Not easily deformed

CNC System

Electrical cabinet

Roller

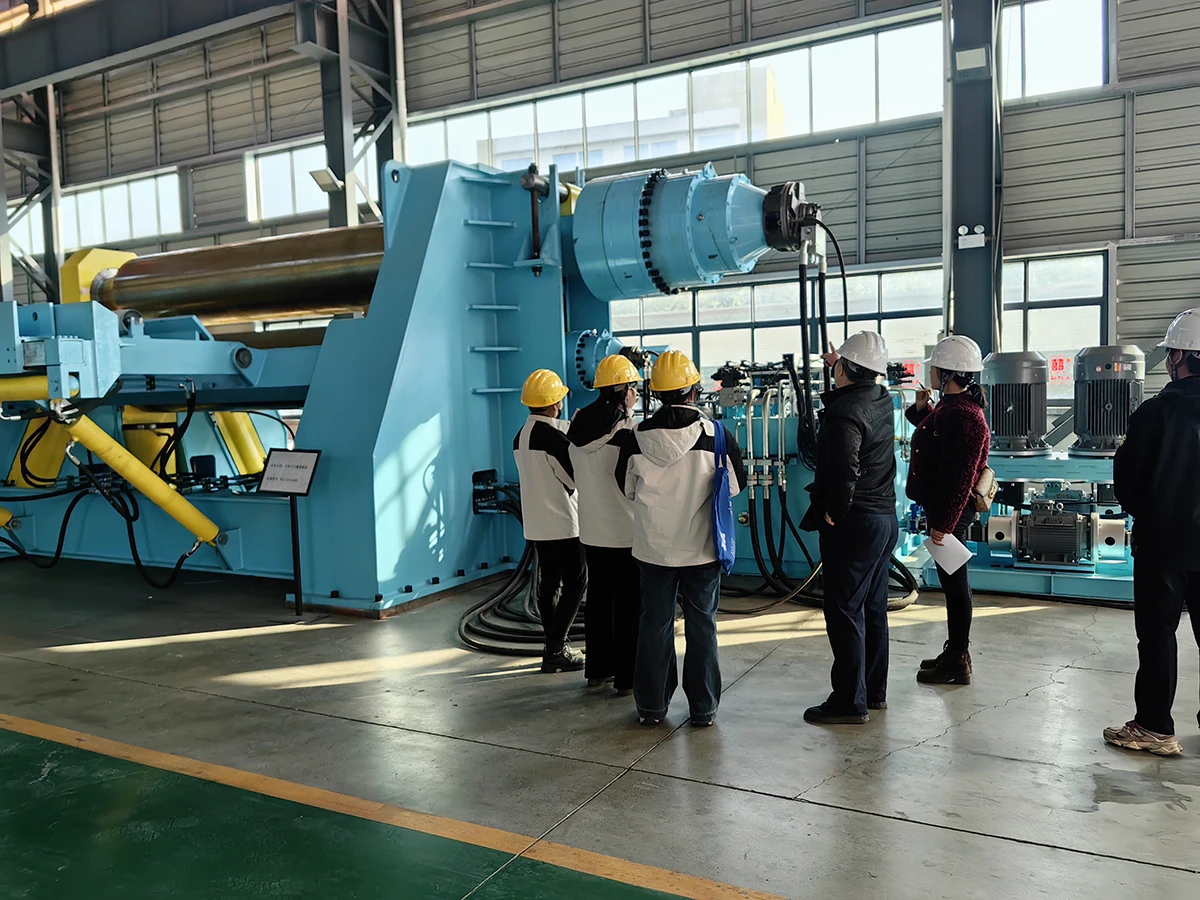

Anhui Colgar Machinery Manufacturing Co., Ltd. is a modern enterprise focusing on R&D, manufacturing, sales and service of a complete set of metal sheet metal equipment. lt mainly produces bending machines, shearing machines, laser and plasma cutting machines, forging press machines, rolling machines, air duct equipment, etc. Other sheet metal processing machines. lt has a modern production plant and is equipped with advanced processing equipment from Germany and Spain. The production is based on the IS09001 management system, and the products have obtained EU CE certification and SGS certification. Factory locates on Maanshan city, Anhui province, covers an area of 50,000 square meters with more than 120 workers.

Web: https://www.rbglty.com

Facebook: https://www.facebook.com/colgar888

Youtube channel: www.youtube.com/@cnccolgar

FAQ&Contact us

Q:How to choose a rolling machine?

A:Please tell us the following information in detail:

- Material of plate:

-Max thickness:

-Max plate width:

-If possible: you can specify the model;

Q:Where is your factory? How can I get there?

A:You can fly to NanJing LuKou airport directly, we will pick you up in the airport. All our customers, both inland and abroad, warmly welcome to visit us!

Q:How do you ensure quality in the factory?

A:Quality culture.:We always attach great importance to quality control from the beginning to the end. Our factory has obtained ISO, CE certification.

Q:How can I pay?

A:You can pay by T/T, Western Union, MoneyGram, Paypal; 30% deposit; pay off the 70% balance before shipment.

Q: How long to produce?

A: Delivery time:15-35 days.

We Recommend

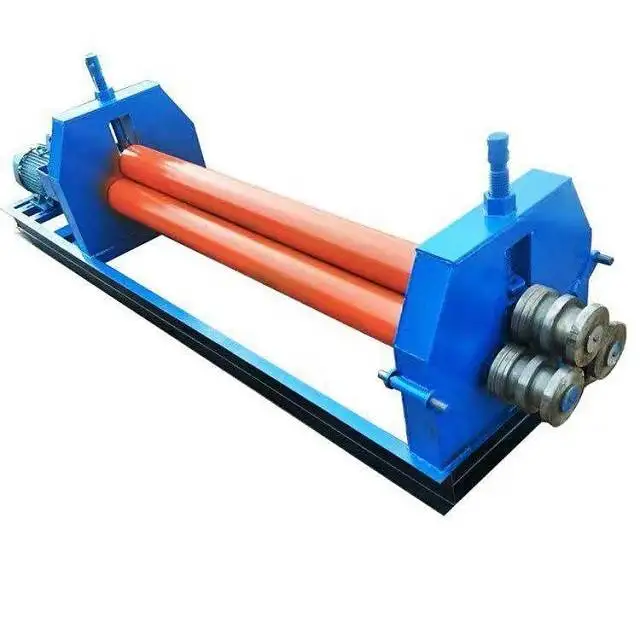

Jiuying W11 различный тип 3-роликовой рулонной машины

$7,200.00-7,400.00

Роликовая гибочная машина для листового железа высшего качества J&Y

$7,200.00-7,400.00

New Arrivals

New products from manufacturers at wholesale prices