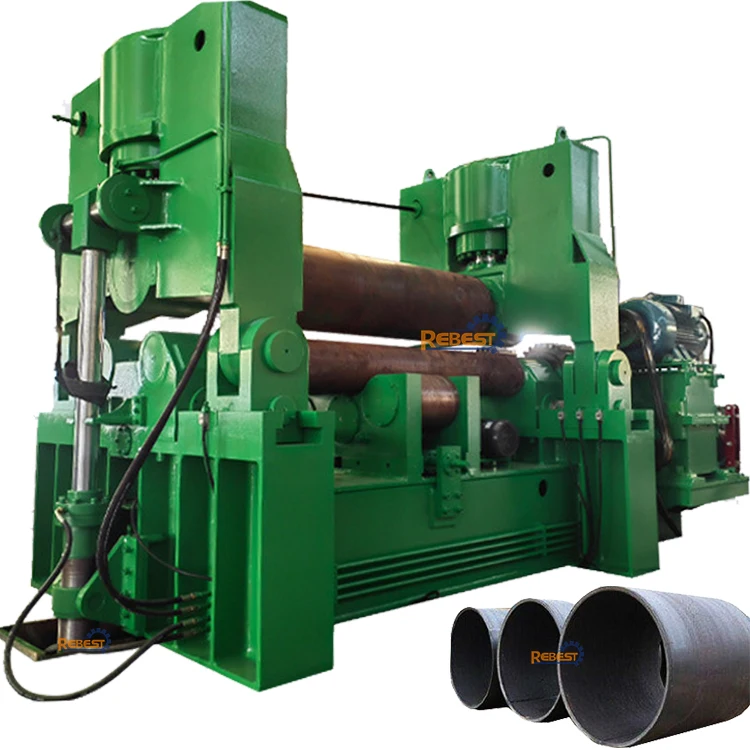

50x3000 W11S Hydraulic Universal Plate Rolling Machine 3 Three Roller Sheet Bending Machine

- Category: >>>

- Supplier: Nantong Rebest Technology Co. Ltd.Nantong Ltd.

Share on (1601364361406):

Product Overview

Description

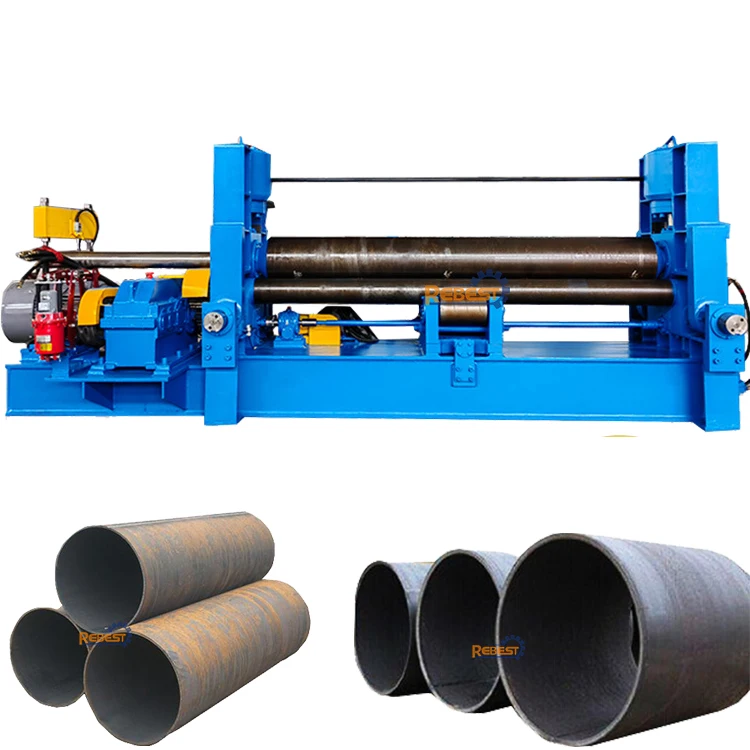

CNC 4 Roller Hydraulic Plate Rolling Machine 10mm 16mm 20mm 30mm 40mm 50mm 60mm 80mm 100mm Thickness 2000mm 3000mm 4000mm Width

Product Overview

● 45° slant bed CNC lathe 3000 rpm independent spindle

● Taiwan THK lead screw wire gauge

● 12-station servo turret-----optional power turret

● Application:

Slant Bed CNC Lathe machine is mainly used for processing all kinds of shaft parts, disk parts, you can turn a variety of threads, arcs, cones and rotary body inside and outside the surface, to meet the ferrous metal and nonferrous metal high-speed cutting speed demand. Suitable for automotive, motorcycle, electronics, aerospace, and other industries on the rotary parts for efficient, high-volume, high-precision processing.

● Taiwan THK lead screw wire gauge

● 12-station servo turret-----optional power turret

● Application:

Slant Bed CNC Lathe machine is mainly used for processing all kinds of shaft parts, disk parts, you can turn a variety of threads, arcs, cones and rotary body inside and outside the surface, to meet the ferrous metal and nonferrous metal high-speed cutting speed demand. Suitable for automotive, motorcycle, electronics, aerospace, and other industries on the rotary parts for efficient, high-volume, high-precision processing.

PRODUCT SPECIFICATIONS

SPECIFICATIONS | CK420 | CK560 | CK650 | CK920 | |||

Max. swing dia. over bed | Φ420 | Φ560 | Φ650 | Φ920 | |||

Max. swing dia. over slide | 120 | 330 | 380 | 600 | |||

Max. working length | 300, 480, 520, 750, 950, 1000 | 800KGS | |||||

Spindle nose | A2-5(6″) | A2-6(8″);*A2-8(10″) | |||||

Main motor power | 5.5/7.5Kw | 11kw, 15kw, 19.5kw | |||||

Max. spindle speed | 5000rpm | 4200rpm | |||||

Spindle bore | Φ56 | Φ66 | |||||

Max. dia. of through-hole | Φ42 | Φ52 | |||||

X axis travel | 460mm | 260mm | |||||

Z axis travel | 400mm | 610mm, 830mm, 1050mm | 830mm | ||||

X/Z rapid traverse | 20/20m/min | 24T Disc Type ATC | |||||

Turret type | without Turret | with Turret | |||||

Center height | 63 | 100 | |||||

Station number | 8 station | 12 station | |||||

1.The precision ball screw produced in Taiwan has good accuracy and rigidity to ensure the good processing accuracy of the machine tool. The hydraulic components are well-known products in China (including Taiwan).

2.Inclined bed structure, bed using integral casting, coupled with a wide base, greatly enhance the stability of the machine tool and vibration resistance.

3.The guide rail is quenched at high frequency, with high wear resistance and stability, and can maintain accuracy for a long time. X, Z can use a higher linear speed, greatly improving the production efficiency of the machine.

2.Inclined bed structure, bed using integral casting, coupled with a wide base, greatly enhance the stability of the machine tool and vibration resistance.

3.The guide rail is quenched at high frequency, with high wear resistance and stability, and can maintain accuracy for a long time. X, Z can use a higher linear speed, greatly improving the production efficiency of the machine.

PRODUCT CONFIGURATION

CNC SYSTEM

SIEMENS;

FANUC;

KND;

MITSUBISHI;

GSK;

Other operating systems can be selected according to requirements.

FANUC;

KND;

MITSUBISHI;

GSK;

Other operating systems can be selected according to requirements.

Optional:

Hydraulic Chuck;

Pneumatic Chuck;

4-Jaw Chuck;

Standard: 12-station servo turret;

Optional power turret: Upgraded to a turning and milling center;

Standard: Manual tailstock

Optional: Hydraulic or Pneumatic Type Tailstock.

Ball screw guide rail

Quenching Guide;

Japan THK ball screw guide rail;

Super Audio Quenching Guide Rail, Guide Rail Hardness HRC50,

Japan THK ball screw guide rail;

Super Audio Quenching Guide Rail, Guide Rail Hardness HRC50,

Timing, quantitative, accurate and efficient;

Efficiently lubricates all parts of the machine tool.

Electrical component adopt famous-brands - Schneider, France;

Top-quality brands guarantee machine's stability and performance;

MACHINE PHOTOS

Product packaging

FACTORY SHOW

1. What is the payment Terms ?

A : T/T, 30% initial payment when order, 70% balance payment before shipment ;

2. What CNC system do you use?

A: FANUC, SIEMENS, MISTSUBISHI, LNC,SYNETC,GSK,etc. It depends on your choice.

3.How can I choose the most suitable machines ?

A: Please let us know your machining demand or machine size ,we can choose the best model for you, or you can choose the exact model by yourself. You can also send us the products drawing ,we will choose the most suitable machines for you .

4. What is your trade terms?

A : FOB, CFR, CIF or others terms are all acceptable.

5. What is your minimum order quantity and warranty?

A: MOQ is one set, and warranty is one year.but we will offer lifetime service for machine.

6. What is the package of the machines?

A: The machines standard packed by wooden case package.

2. What CNC system do you use?

A: FANUC, SIEMENS, MISTSUBISHI, LNC,SYNETC,GSK,etc. It depends on your choice.

3.How can I choose the most suitable machines ?

A: Please let us know your machining demand or machine size ,we can choose the best model for you, or you can choose the exact model by yourself. You can also send us the products drawing ,we will choose the most suitable machines for you .

4. What is your trade terms?

A : FOB, CFR, CIF or others terms are all acceptable.

5. What is your minimum order quantity and warranty?

A: MOQ is one set, and warranty is one year.but we will offer lifetime service for machine.

6. What is the package of the machines?

A: The machines standard packed by wooden case package.

We Recommend

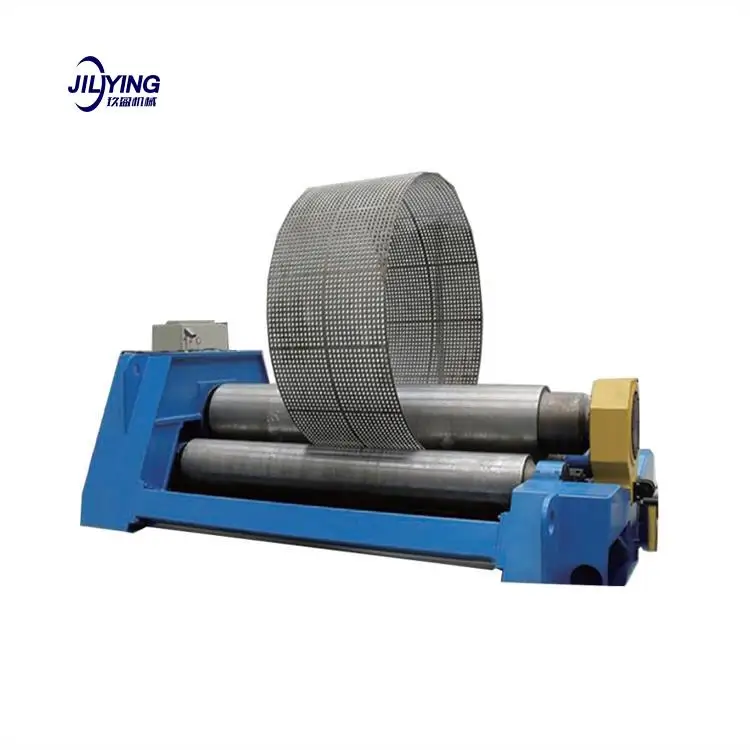

Jiuying W11 различный тип 3-роликовой рулонной машины

$7,200.00-7,400.00

Роликовая гибочная машина для листового железа высшего качества J&Y

$7,200.00-7,400.00

New Arrivals

New products from manufacturers at wholesale prices