New Argon Arc Welding TiG Plasma Automatic Welding Machine

- Category: >>>

- Supplier: Shanghai Mwelding Intelligent Technology Co. Ltd.Shanghai Ltd.

Share on (1601363765811):

Product Overview

Description

New Argon Arc Welding TiG Plasma Automatic Welding Machine

Due to the difference of customized models, more technical parameters are subject to the equipment technical agreement

PRODUCT INTRODUCTION

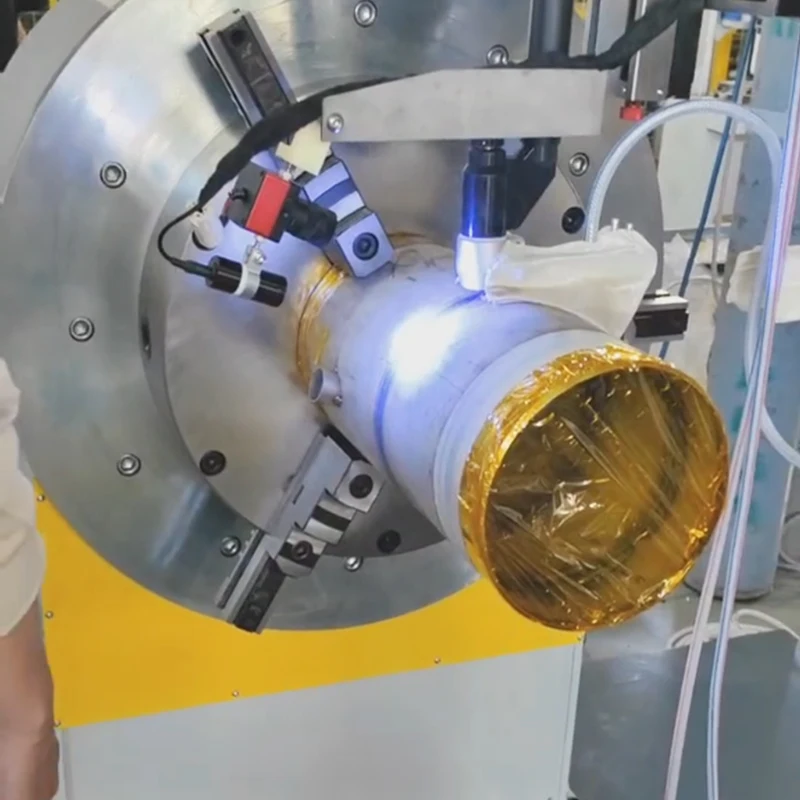

Plasma welding The energy to melt the metal during welding is provided by a highly concentrated plasma spray arc.

Plasma arc is a free arc between cathode and anode compressed by plasma gun into high temperature, high ionization, high energy density and high flame velocity arc.

Plasma welding technology is generally considered to be the main welding technology beyond the non-melting stage inert gas shielded arc (TIG welding).

| 12 mm without beveling, preparation work is greatly reduced, and the filling metal is reduced; |

| The same high quality weld can be obtained for TIG welding; |  |

| Keyhole plasma welding ensures a single pass penetration on a work piece that has been spot welded by hand; |

| With the help of reliable pinhole technology, the quality of the lap joint is perfect; |  |

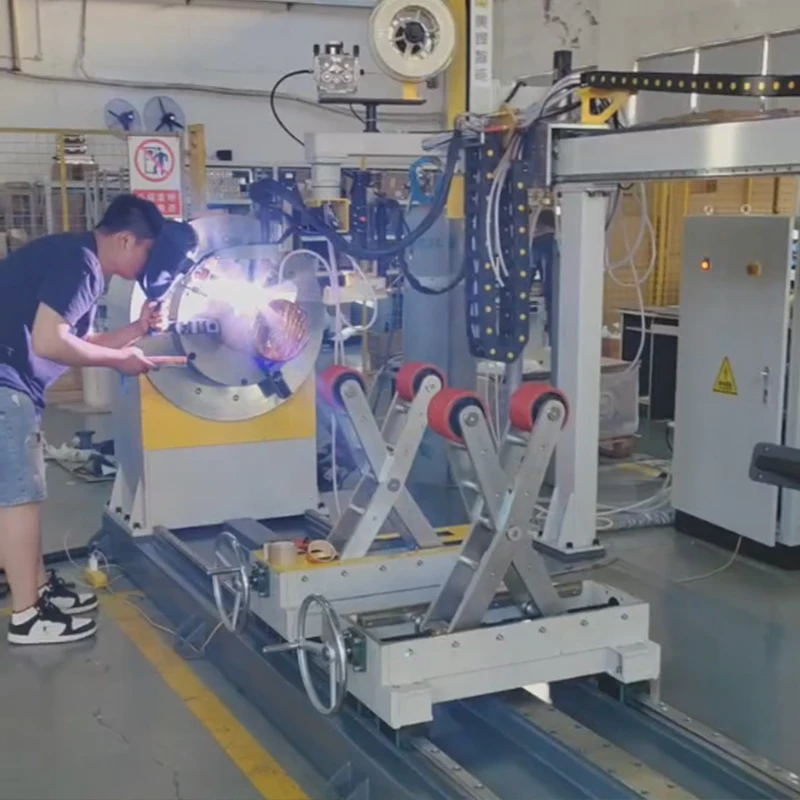

| Assembly speed is 4 to 5 times of manual welding; suitable for automatic welding process: can be reused. |

| Welding system | Automatic plasma welding system |

| Workpiece material | Carbon steel, stainless steel, titanium alloy, nickel alloy, etc |

| Welding type | Circumferential and longitudinal seam welding of pipes, cylinders and plates |

| structural style | Operate frame welding machine, edge beam welding machine, circumferential welding machine, longitudinal welding machine, panel welding machine, etc; Various structures, which can be customized as required |

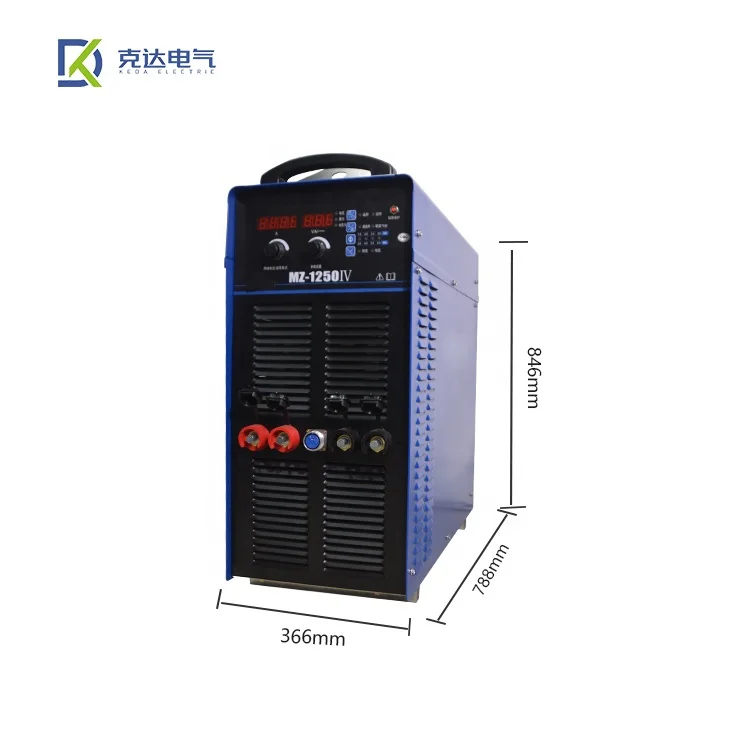

| Optional power supply | Austria - Voronius, Germany - EWM Ida Germany - REHM, Japan - Panasonic Japan - OTC Odich et al |

| Main control system | Germany-SIEMENS,Japan-Mitsubishi, China-XINJIE, etc |

Shanghai MWelding Intelligent Technology Co., Ltd

Shanghai MWelding Intelligent Technology Co., Ltd. was established in 2012, focusing on the production of fully automated pipe welding equipment, automated specialized welding equipment, and integrated welding control power supply as a technology-based innovative technology enterprise. The company adheres to the business philosophy of "customer-oriented, customized, and integrated services without outsourcing", focusing on innovative research and development, processing and production, marketing, and after-sales service. We continuously innovate and optimize our research and development, providing customers with comprehensive technical solutions and high value-added services.

Won honors such as high-tech enterprise,

ISO9001 certification, ISO45001 certification, CE certification,

multiple utility model invention patents, and national AAA level integrity enterprise

1.Where is your factory located?

Our factory is located at Building 7, No.669 Zhongde Road, Songjiang District, Shanghai. Welcome to visit us anytime!

2.Does your company have any qualification certificates?

Yes, our company is a national high-tech, ISO and CE certified enterprise, with multiple patent certificates.

3.What is orbital welding and what can orbital welding machines be used for?

Orbital welding is a technique that connect two objects under a high level of heat. The argon arc automatically rotates 360 degrees around the tubes to create high-quality welds with the control of digital system.

Automatic orbital welding machines can be applied in various industries, such as heat exchanger, pharmaceutical, food, cooling, water treatment, pressure vessel, boiler and many other fields.

4.What are the advantages of automatic welding machines?

After the application of automatic welding machines, the appearance and internal quality of welded parts have been greatly improved. The stability of quality has been ensured while reducing labor intensity, improving the working environment, reducing manual welding skill requirements and production costs, and increasing production efficiency.

5.What other products does your company offer?

Our company offers pipe to pipe welding machine, all position tube sheet welding machine, u-shaped tube welding machine for heat exchanger, automatic circumferential seam welding machine, hot wire overlaying welding machine, argon arc welding machine, orbital welding machine for stainless steel pipe, and so on.

6.Does the company provide customized services for welding machines?

Yes, our company has been focusing on the production, research and development, and design of automatic welding equipment for over ten years. We have professional engineers and technicians to customize according to your specific requirements and needs.

7.How is your company's after-sales service?

We have established an instant response mechanism, where technicians can answer your questions about the operation process anytime and anywhere. We promise to response the email consultation content within 6 hours

For customers, we will arrange professional personnel for on-site operation training, and each equipment will also be equipped with standard operation training manuals for reference

All equipment is uniformly guaranteed for at least one year, and regular maintenance services are provided to reduce equipment consumption, save equipment maintenance costs and operating costs

8.How should I choose the product I need?

Contact us directly through our website, email, WhatsApp, or phone. Please provide your requirements and needs, such as pipeline type, welding materials, delivery time, quantity, customization requirements, etc. Once we receive the information, our sales will help you select the welding machine that best meets your requirements, provide you with a detailed quotation, and answer any questions you may have.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices