eps cement sandwich panel production line/fiber cement board machine,/lightweight concrete wall panel forming machine

- Category: >>>

- Supplier: Ningjin Shuangli Building Materials Equipment Co. Ltd.Ningjin Ltd.

Share on (60403989005):

Product Overview

Description

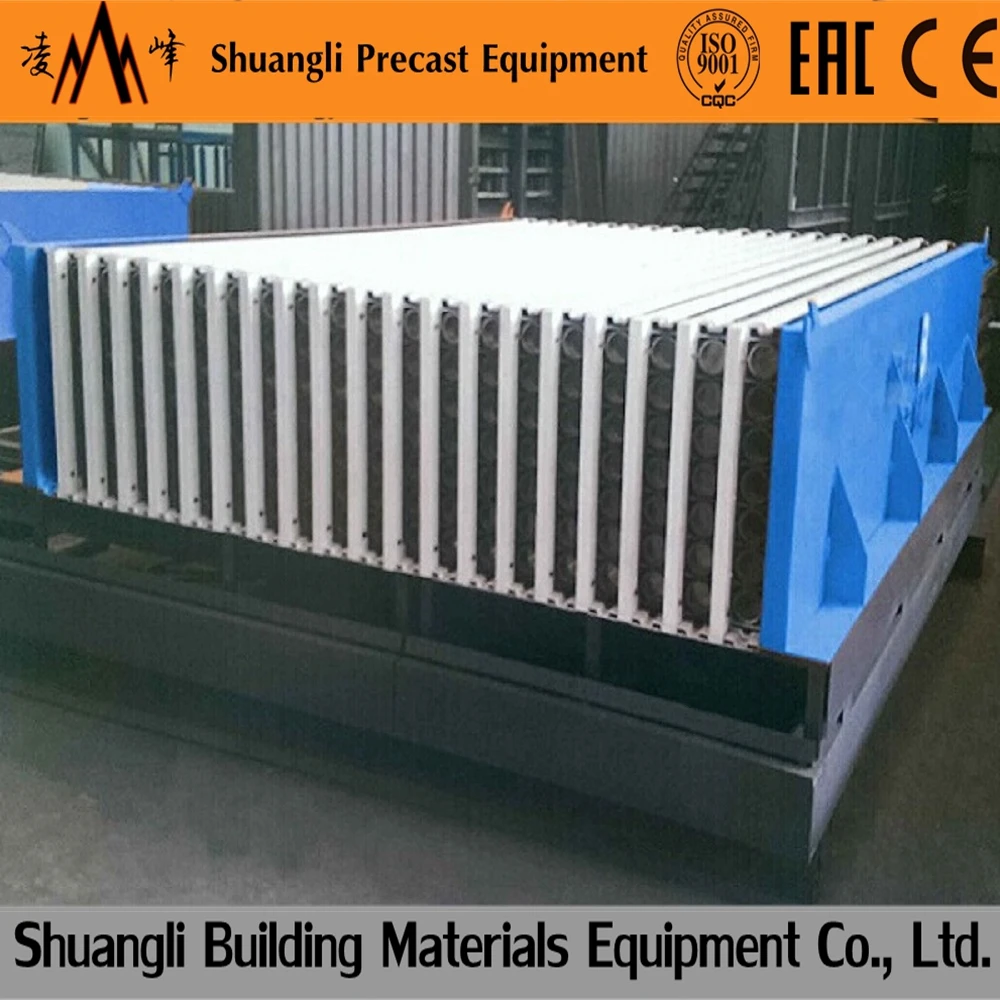

eps cement sandwich panel production line/fiber cement board machine,/lightweight concrete wall panel forming machine

Introduction of eps cement sandwich panel production line/fiber cement board machine,/lightweight concrete wall panel forming machine

The machine uses hydraulic lifting system, easy to revolve. It can reduce labor intensity and improve production efficiency.

Machine body adopts anti-rust technology. Key parts like hopper, is welded with stainless steel. Wearing parts like reamers, side form, vibration board, stock guide and other parts are all welded with the best YG alloy.

Both sides of the wall panels can be put reinforcement wires, diameter can reach 6mm.

Work area: With or without orbital.

Panel materials: According to the specialty of the local materials, we provide matching method to make sure standard panels (general materials: fly ash, slag, ceramic,cinders,pumice,vermiculite, etc)

Reduce the overall cost of the building, increase indoor usable space.

High production efficiency, annual output square meters above 150000 m2.

Advantages & Details of eps cement sandwich panel production line/fiber cement board machine,/lightweight concrete wall panel forming machine

1. LF lightweight wall panel machine is a movable producing panel machine which need platform to move during producing.

2. Thin steel wire 2mm-3mm are put inside the panel in advance before producing.

3. The machine is applied to high tech. Extrusion technique can make the panels more density and surface much smoother.

4. Shuangli Building Materials Equipment Co., Ltd. was rewarded with the patent for LF lightweight panel machine.

5. Material: cement, fly ash, slag ,expand perlite/cement, sand/pre-stressed steel wire used. Better use lightweight materials.

Model | Slab width (mm) | Slab thickness (mm) | Dia of Holes | Forming speed (m/min) | Motor Power (KW) | Vibrator (KW) | Dimension (m) | Weight (kg) |

80*600 | 595±2 | 78±1 | 8xΦ43 | >=1.6 | 4 | 0.8 | 2.5*0.95*0.75 | 1260 |

90*600 | 595±2 | 88±1 | 7xΦ58 | >=1.6 | 5.5 | 0.8 | 2.5*0.95*0.70 | 1260 |

100*600 | 595±2 | 98±1 | 7xΦ62 | >=1.6 | 5.5 | 0.8 | 2.5*0.95*0.75 | 1400 |

120*600 | 595±2 | 118±1 | 5xΦ82 | >=1.6 | 5.5 | 0.8 | 2.55*0.95*0.75 | 1650 |

150*600 | 595±2 | 148±1 | 4xΦ100 | >=1.6 | 5.5 | 0.8 | 2.65*1.0*0.8 | 1650 |

200*600 | 595±2 | 198±1 | 3xΦ145 | >=1.6 | 7.5 | 3 | 2.65*1.0*0.85 | 1680 |

Concrete Fence Production-

Production video from YouTube: https://www.youtube.com/watch?v=sRd_082ga3o

Lightweight Wall Panel Extruder-

Production video from YouTube: https://www.youtube.com/watch?v=_qf6Cd_bxxc

∨

We Recommend

New Arrivals

New products from manufacturers at wholesale prices