новое состояние машины печи для сушки древесины

- Категория: >>>

- Поставщик: Guangzhou Kaineng Electric Equipment Co. Ltd.

Сохранить в закладки 1100003983432:

Описание и отзывы

Характеристики

New Condition machinery wood drying kiln

MODEL | JK10RD | |||

Suitable for drying chamber | m3 | 30-50 | ||

Input power | KW | 11.25 | ||

Heating capacity | KW | 35.00 | ||

Cooling capacity | KW | 25.00 | ||

Dehydration capacity | L/H | 40 | ||

Temperature | ℃ | 60/75 | ||

Working ambient temperature | ℃ | -10~45 | ||

Refrigerant |

| Mixture type | ||

Compressor type |

| Scroll | ||

Compressor brand | Brand | Copeland/Danfoss | ||

Compressor quantity | units | 2 | ||

Noise | dB(A) | 60 | ||

Power supply | V | 380 | ||

Frequency | HZ | 50 | ||

Fan motor for drying 1 (1 units) | Power input | 550W | ||

| Wind volume | 5870m3/H | ||

| Rotate speed | 1400R/M | ||

Fan motor for drying 2 (1 units) | Power input | 750W | ||

| Wind volume | 4426m3/H | ||

| Rotate speed | 2900R/M | ||

Fan motor for exchange air (1 units) | Power input | 150W | ||

| Wind volume | 2000m3/H | ||

| Rotate speed | 700R/M | ||

Fan motor for exchange fresh air | Power input | 6W | ||

| OPEN | Exchange fresh air | ||

| CLOSE | Drying | ||

Fan motor for evaporator (2 units) | Power input | 2*550W | ||

| Wind volume | 2*6000m3/H | ||

| Rotate speed | 2*1410R/M | ||

Wind pipe connector size 1 (2 supply-air outlet) | mm | 400*400 | ||

Wind pipe connector size 2 (1 supply-air outlet) | mm | 1150*560 | ||

Dimension(L*W*H) | mm | 2055*1370*1690 | ||

Weight | Net weight | Kg | 480 | |

| Gross weight |

| 540 | |

1. Energy saving&Environmental protection

Adopt close dehumidify+circulating drying type,saving operating cost;

Without waste gas and waste heat pollution,low noise

2. Running Stable,operating easily

PLC+Touch Screen,running stable,operating easily;

Adopt PLC control,can setting different drying curve,

Suitable for drying different materials.

3. Second waste heat recovery technology(patent)

Adopt air to air heat exchanger dehumidify and recovery waste heat at the same time, saving energy more than 40%.

4. Exact control temperature and humidity

According to different material setting different drying curve,

the heat pump dryer can control the drying

chamber temperature between 20-80℃

5. Recovery volatilized component

Some kinds of material contain volatilized component,

In drying processing,hot and wet air will become condenser water then drain,

collect the condenser water so that collect volatilized component

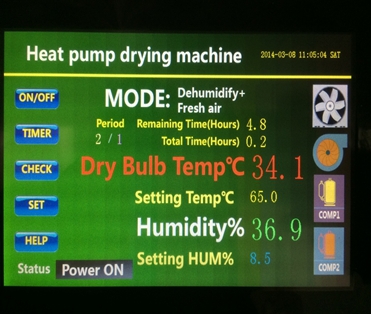

controller panel

Похожие товары

3 кг 5 6 Китай пол фрукты вакуумной заморозки сушильная машина

Китайский завод небольшая пескосушилка для песка кварцевый камень 3-проходная барабанная сушилка цена в Турции

Горячая Распродажа фармацевтическая промышленная ротационная сушил

Высокоэффективная распылительная сушилка двойной циклон 2 л/ч мочевина Формальдегид машина с компрессором

Большая шкала 50m2 промышленный дом appliabce замораживания сушилка

Промышленная вакуумная ленточная сушилка Minjie низкотемпературная технология сушки для защиты биологической среды здравоохранения

Хорошее качество песка сушки производственной линии кварцевый песок сушилка завод

Новые поступления

Новинки товаров от производителей по оптовым ценам