Горячая распродажа! Автоматическое оборудование для производства древесных гранул Одобрено CE

- Категория: >>>

- Поставщик: Liyang Rongda Machinery Co. Ltd.

Сохранить в закладки 1524598988:

Описание и отзывы

Характеристики

Professional Real Manufacturer of wood pellet plant!

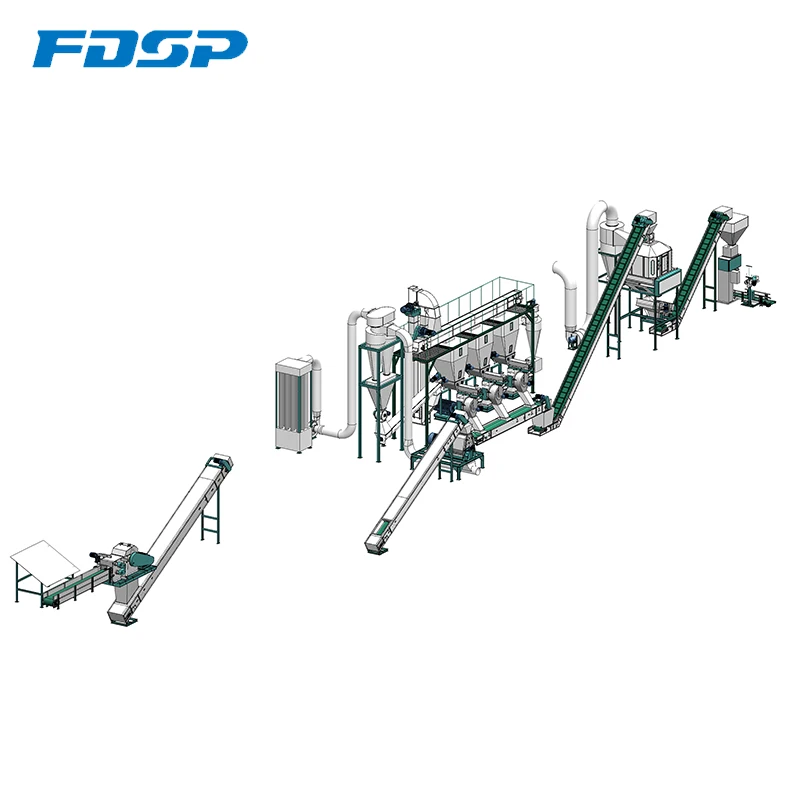

Hot sale! CE approved automatic wood pellet plant production system equipment

wood pellet plant

Details of our pellet machine:

Ring die pelleting machine with better quality pellets and higher capacity

Gear drive with stronger power

Stainless steel ring die or alloy steel ring die

CE & Gost certificate for European countries and Russia.

NSK Bearing or SKF Bearing according to customer need.

wood pellet plant

The production line involves in the all single devices aiming to produce the final products, which includes the biomass pellet production line, wood chips production line and feed production line etc. The biomass production line serves for new biomass energy to produce the biomass fuel with wood, sawdust, rice husk, EFB, grass, straw and other biomass materials. The wood chips production line designed with different demands is our new promotion in the purpose of making wood chips.

Pelletizing is the process of making waste materials into solid fuel. The objects are used for burning purposes. Biomass Pellet can be made from any type of Agro-Forestry waste.

wood pellet plant

wood pellet plant Features

1. Reasonable technology, high capacity and low energy consumption.

2. Modular Structure: The plant is compact, occupies less floor space and has low requirement on the mill tower, and needs low investment in civil works.

3. The containerized modular structure is convenient for assembly and disassembly, facilitates the shipment and installation.

4. Centralized control: the analogue panel is adopted. All machines can be interlocked and safety, alarm device is available. The operation is simple and convenient.

wood pellet plant

wood pellet plant Production Sequence

1. Peeling Process

2. Chipping Process

3. Drying Process

4. Grinding Process

5. Pelletizing Process

6. Cooling and Sieving Process

7. Packing Process

w ood pellet plant

ood pellet plant

About Service

We insist on "Quality is the soul of company" and take customers as our god, owned outstanding R&D team with the sense of innovation and cooperation, timely and effectively after-sales service team, professional installation guidance team. We devote to all-round service of all the products from shipment to maintenance.

Our professional service includes: Free training, Guidance Installation and Debugging.

Guaranteed Time: One Year

If you have any question, please contact us freely. Our after-sales service team on-line will do the best to accomplish your sincere requirement on time.

Thank you for your reliance and support!

The following photos that we have installed both home and abroad for your reference:

14-16t/h wood pellet line

4t/h wood pellet line

wood pellet plant

8t/h eucalyptus wood pellet plant

Finished wood pellets from our pellet machine.

Our certificates:

Delivery Management: When the container arrived our factory, our shipping operator and delivering equipments will be ready on time to ensure goods shipped based on Sales Order requirement.

About us:

We are specialized in designing and manufacturing biomass pellet machinery ,poultry feed,aquatic feed pellet machinery,and the complete production line(all auxiliary equipment) with CPM advanced technology.

The current products include: hammer mill, ingredient weighing system, mixer, pellet mill, counter-flow cooler, dryer, crumbler, rotary screener, liquid adding equipment, pulse filter equipment, horizontal and vertical conveying equipment, links and gates, permanent magnet cylinder, and de-iron equipment etc.

Liyang Rongda Machinery CO.,LTD. located in Daitou Industrial Zone with 25000 square meters area,Liyang city,Jiangsu province,China.

Frequently Asked Questions:

1. Q: Are you a trading company or a manufacturer?

A: We are a manufacturer, which has almost 20 years of experience in this industry.

2. Q: How can I get to your company?

A: You can get a flight to Nanjing Lukou Airport. We are just about 40-50mins away from Nanjing Airport.

You may also come to our city,Liyang city by High speed Railway,just 20-30mins.

3. Q: How long is your guarantee?

A: One year(Calculated from the equipment arrives the customer’s side.). After this period we will definitely support you when needed. You will be welcome to contact us with any problem may happened.

4. Q: Will you send engineers to install the plant?

A: yes, but at an extra cost payable by the customer. Or you can get local contractors to do the commissioning and we send one supervising engineer.

5. Q: Do you have some foreign customers using your equipment?

A: yes, we have.our company has established business relationships with customers in Russia,German,Slovakia,Ukraine,Vietnam,Pakistan, the Philippines, Indonesia, Thailand, Pakistan, Egypt ,Iraq,Jordan,Saudi Arabia,Syria, Libya etc.

Sharon Yang

Manager

Похожие товары

Стабильное производство древесных материалов, биомасса, сжигание гранул, завод по производству

Sinomach Китай бренд Shantui строительный автогрейдер для продажи GP310M

Всемирно известный автогрейдер Sinomach PY200MH по низкой цене

23340 NSK NTN Koyo сферический роликовый подшипник 23340

Хорошее качество, портативная перезаряжаемая через USB бритва, бритва для бороды, для мужчин

Лидер продаж, Корейская импортная машина для выпечки риса для малого бизнеса

SHANTUI 22t Гидравлический Вибрационный дорожный уплотнитель SR22M-C5

Новые поступления

Новинки товаров от производителей по оптовым ценам