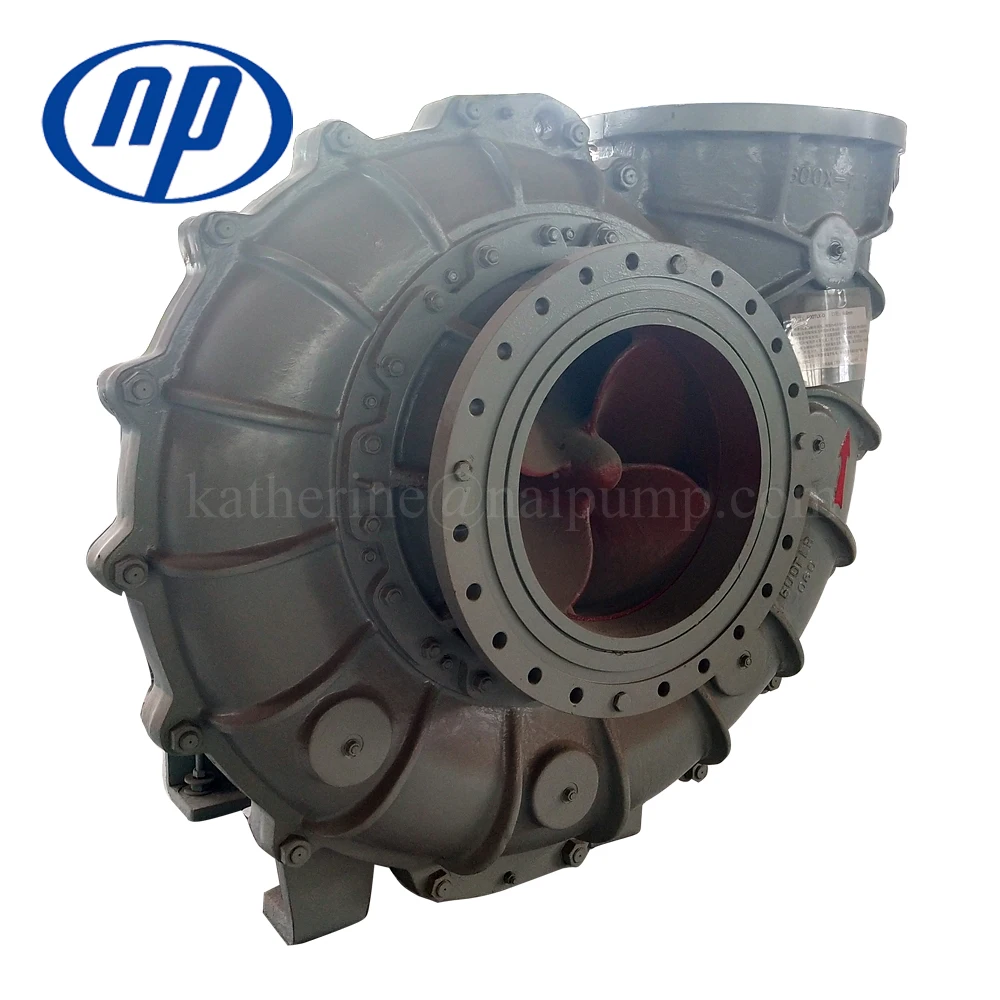

Мощный десульфурационный насос Naipu 600TL FGD для электростанции

- Категория: >>>

- Поставщик: Shijiazhuang Naipu Pump Co. Ltd.

Сохранить в закладки 1600064311231:

Описание и отзывы

Характеристики

Naipu 600TL Rubber Liner Heavy Duty FGD Desulfurization Pump for Power Plant

FGD Slurry Pump

Size: 350-1000mm

Capacity: 1600-15000m3/h

Head: 5-94m

Materials: Hyper chrome alloy or Rubber etc.

The desulphurization pump are mainly used to handle slurry with smoke in absorption tower of electric power station, that is thermal power plant FGD (Flue Gas Desulfurization) Project.

Desulfurization Pump Design Features

• TL(R) FGD slurry pump wetted parts adopt the advanced flow simulation technology to guarantee reliable design and high operating efficiency.

• Corrosion resistant and wear resistant metal and rubber materials for opitions

• The special integrated mechanical seal design is suitable to Thermal Power Plant Fuel Gas Desulphurization process.

• The bearing at pump end is double-row taper roller bearing, and bearing at drive end is cylindrical roller bearing. The bearings are lubricated with oil to longer the service time

• Achieve highest efficiency all the time by adjusting the bearing components to alter the impeller position in pump chamber

• The pump can be disassembled without dismantling suction or discharge pipes

FGD Slurry Pump Applications

FGD system

Mainly used as the circulating pump for absorption tower in FGD system

Sulfuric acid phosphate fertilizer

Transportating acid, liquor, sewage, water, fluoride acid containing silica, phosphate slurry and other media.

Non-ferrous metal smelting

Particularly used for lead, zinc, gold, silver, copper, manganese, cobalt, rare earth and other various hydrometallurgical acid, corrosive pulp slurry (filter press equipped with) electrolyte , sewage and other media delivery.

Oil & Chemical

Variety of sulfuric acid, hydrochloric acid, alkaline, clear liquid or slurry oils posts. Titanium dioxide, iron Pink production, various dyes, pigments production, non-metallic mineral processing industries.

Chlor-alkali industries

Hydrochloric acid, caustic electrolyte etc.

Water Treatment

Pure water, high pure water, wastewater (sewage leather, electroplating wastewater, electronics sewage, papermaking sewage, textile sewage, food waste water, sewage, sewage pharmaceutical industry, etc.).

Iron and steel

sulfuric acid system, hydrochloric acid positions, with impurities sewage.

Coal industries

Coal corrosive liquids, coal slurry transportation

Type | Capacity (m3/h) | Head (m) | Speed (r/min) | Maximum efficiency η(%) | NPSH (m) | Outlet diameter (mm) | Inlet diameter (mm) |

350X-TL(R) | 1600 | 25 | 960 | 82 | 4.5 | 350 | 400 |

400X-TL(R) | 2500 | 25 | 725 | 83 | 5.0 | 400 | 450 |

500X-TL(R) | 3750 | 25 | 725 | 85 | 5.0 | 500 | 500 |

600X-TL(R) | 6300 | 25.5 | 620 | 88 | 5.5 | 600 | 700 |

700X-TL(R) | 6840 | 26 | 485 | 87 | 6.0 | 700 | 800 |

800X-TL(R) | 9360 | 31 | 485 | 90 | 7.0 | 800 | 900 |

900X-TL(R) | 15000 | 30 | 485 | 90 | 8.5 | 900 | 1000 |

1000X-TL | 10440 | 15 | 485 | 89 | 7.0 | 1000 | 1200 |

FGD Slurry pump construction drawing

TLR Rubber Lined:

| NO. | Name | Material | NO. | Name | Material |

| 1 | Frame | Cast Iron | 7 | Suction Cover | Duplex stainless steel |

| 2 | Impeller Release Collar | Stainless Steel | 8 | Impeller | Duplex stainless steel |

| 3 | Shaft Sleeve | ZG0Cr18Ni12Mo2Ti | 9 | Cover Plate | QT500-7 Ductile iron |

| 4 | Mechanical Seal | Hard Alloy | 10 | Frame Plate Liner | Natural Rubber+A3 |

| 5 | Frame plate Liner Insert | Natural Rubber+A3 | 11 | Frame Plate | QT500-7 Ductile iron |

| 6 | Cover Plate Liner | Natural Rubber+A3 | 12 | Adaptor Plate | QT500-7 Ductile iron |

TL Metal Lined:

| NO. | Name | Material | NO. | Name | Material |

| 1 | Frame | Cast Iron | 7 | Throatbushing | Duplex stainless steel |

| 2 | Impeller Release Collar | Stainless Steel | 8 | Impeller | Duplex stainless steel |

| 3 | Shaft Sleeve | ZG0Cr18Ni12Mo2Ti | 9 | Suction Cover | QT500-7+Rubber |

| 4 | Mechanical Seal | Hard Alloy | 10 | Cover Plate | QT500-7 Ductile Iron |

| 5 | Frame plate Liner insert | Duplex stainless steel | 11 | Frame Plate | QT500-7 Ductile Iron |

| 6 | Volute liner | Duplex stainless steel | 12 | Adaptor Plate | QT500-7 Ductile Iron |

CE, SGS, ISO9001 Certification

Naipu Slurry Pump Models

NPAH(R) | L(R), M | HH | SP(R) | G | AF Series |

1.5/1B-NPAH(R) | 20A-L | 1.5/1 C-HH | 40PV-SP(R) | 6/4D-G | 2QV-AF |

2/1.5B-NPAH(R) | 50B-L(R) | 3/2D-HH | 65QV-SP(R) | 8/6E-G | 3QV-AF |

3/2C-NPAH(R) | 75C-L | 4/3E-HH | 100RV-SP(R) | 10/8F-G | 6SV-AF |

4/3C-NPAH(R) | 100 D-L | 4/3X-HH | 150SV-SP(R) | 10/8S-G | 8SV-AF |

6/4D-NPAH(R) | 150E-L | 6/4F-HH | 200SV-SP | 12/10G-G |

|

6/4E-NPAH(R) | 300S-L | 6/4X-HH | 250TV-SP | 14/12G-G |

|

8/6E-NPAH(R) | 10/8 R-M | 6S-H |

| 14/12T-G |

|

8/6R-NPAH(R) | 10/8 E-M | 8/6S-H |

| 16/14 G-G |

|

10/8F-NPAH(R) |

| 8/6X-H |

| 16/14TU-GH |

|

10/8X-NPAH(R) |

| 6S-HP |

| 16/14H-GH |

|

12/10ST-NPAH(R) |

| 8/6S-HP |

| 18/16G-G |

|

14/12ST-NPAH(R) |

| 8/6X-HP |

| 18/16TU-GH |

|

16/14TU-NPAH(R) |

|

|

|

|

|

20/18G(TU)-NPAH(R) |

|

|

|

|

|

Naipu pump produce many kinds of centrifugal slurry pump for mining, sand and other solids slurry transporting.

|  |

| 6/4 ZJ Slurry Pump | 8/6 ZJ Pump |

|  |

| E044 | E062 |

Shijiazhuang Naipu Pump Co., Ltd is a professional manufacturing enterprise of slurry pumps and spare parts. Which own Mould Workshop, Casting Workshp, Machining Workshop and Assembly Workshop.

Packaging details

1. Outside package: standard export wooden cases.

2. Inner package: Stretch film.

Contact Person: Katherine Hou

Похожие товары

Высокопроизводительные шламовые насосы allen sherman hoff с сертификатом CE

ЗАПАСНЫЕ ЧАСТИ К НАСОСАМ ДЛЯ ГОРНОДОБЫВАЮЩЕЙ ПРОМЫШЛЕННОСТИ Погружн

Высокая температура dc 24v циркуляционный мини-бочонок для пива женские туфли-лодочки

Одноступенчатый без утечки кислородного масла из нержавеющей стали насос для теплопередачи охладителя

Химически стойкий насос постоянного потока с магнитным приводом

Сопротивление химическим низким расходом струйный принтер Запасные части насос

JIHPUMP все серии маленький мини микро 6 В 12 24 большой поток 110v220v OEM перистальтический насос для дозирования жидкости воды цена

Новые поступления

Новинки товаров от производителей по оптовым ценам