Мини лаборатория 6/12 шпиндель причудливый вращающийся станок DW7043H

- Категория: Spinning Machines >>>

- Поставщик: Hefei Fanyuan Instrument Co. Ltd.

Сохранить в закладки 1600070470247:

Описание и отзывы

Характеристики

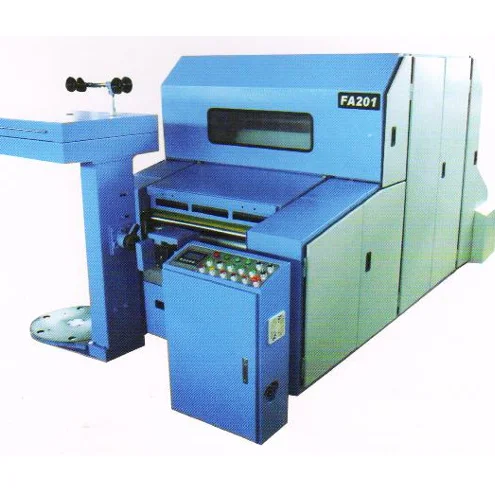

DW7043H Fancy Spinning Machine

Application of Fancy Spinning Machine:

DW7043H FANCY SPINNING MACHINE is used to spin various fancy yarns of different color or structure by changing the drafting ratio and number of twists. It also can be used to spin yarns with relative attachments (optional).

Fancy yarns are generally composed of 3 yarns, namely core yarn, solid yarn and decorative yarn.Core yarn plays a skeleton role and mainly provides yarn strength. Filament or yarn with higher strength is generally selected as the core yarn. The fixed yarn ACTS as a reinforcement to fix the shape of the flower in the way Fancy Spinning Machine was produced without sliding along the length. Most solid yarns are made of thin filament with high strength. The decorative yarn reflects the fancy effect. The fancy yarn, such as rough details, circles, and pigtails, is presented through the decorative yarn. Decorative yarns can be made of cotton sliver or roving with the same draft but different overfeed (e.g., loop yarns), or by different overfeed (e.g., slub yarns), or by filament yarns with different overfeed (e.g., knotted yarns). Sometimes, two roving yarns of different colors with different drafts and different overfeeding can produce fancy yarns with not only varying thickness but also varying color.

The production principle is as follows: the core yarn is transported by the core roller and enters the hollow spindle through the guide roller. When the yarn enters a hollow spindle through a drawing mechanism, the feeding speed of the yarn (generally overfeeding) keeps changing. The retainer draws from the hollow spindle bobbin and enters the hollow spindle together. Three yarns are fed at the same time. Before twisting, the core and the yarn rotate with the hollow spindle to obtain false twist, while the solid is unwound from the hollow spindle and parallel to the core and the yarn without false twist. After twisting, the false twist of the core yarn and the decoration yarn disappears, and the fixed yarn is wrapped on the core yarn and the decoration yarn, and the flower shape formed by the overfeeding of the decoration yarn is fixed down to form the fancy yarn. Core yarn must have certain tension, decorative yarn must have overfeed, fixed wire must be wrapped. In the whole spinning process, the drawing is completed once to form the flower-shaped and winding process.

Key specification of Fancy Spinning Machine:

Fiber length | 22~42mm |

Control method | Touch panel & PLC |

Ring speed | 12000rpm |

Spindles | 4/6 |

Twist range | Approx. 200~2000T/m |

Drafting ratio | Approx. 2~50 |

Roll diameter | Φ25mm |

Power supply | AC220V, 50Hz |

What material to use:

l Aluminum profile body frame with four casters, free to move;

l Modular independent drive for drafting, spindle blade and flyer;

l Three-up-three-down drafting structure

l Equipped with More spare parts

l Multi-functional design, easy to clean, set and maintain;

l Beautiful internal circuit

l Unique structure easy to hang yarn

Installation in customer's lab Training in FYI showroom

Customer in our factory

Standard wooden packaging

Installation notes of fancy spinning machine

Environment required to install the machine must meet requirements as below:

l Dry place, no drips, steam or oily dust;

l No corrosive, flammable gas or liquid;

l Solid base and no vibration;

l No electromagnetism and noise;

l To minimize electrostatic charge, it is much better if constant temperature & humidity room, 28℃;

Похожие товары

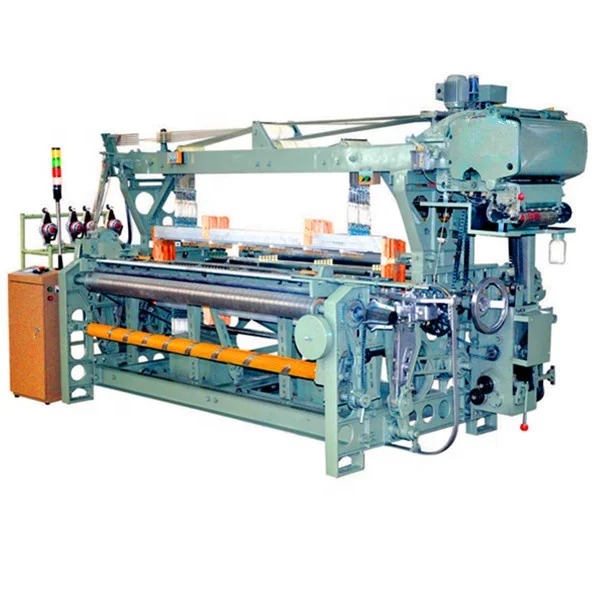

Китай, ткацкий станок для футболок, цена

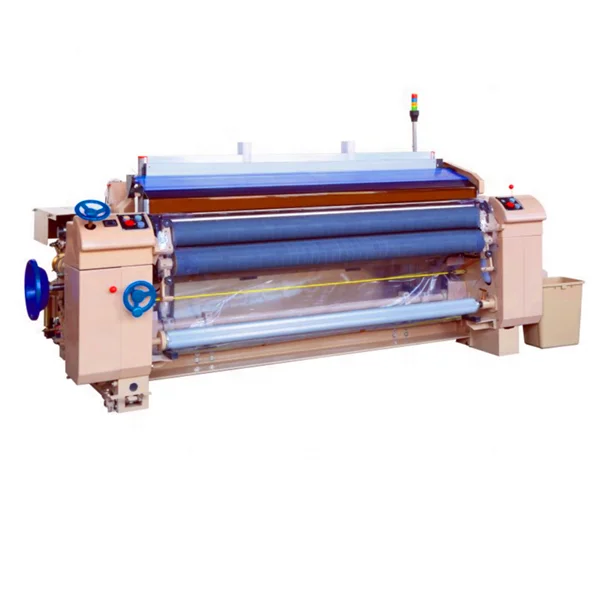

Сеточная ткацкая машина для насекомых высокоскоростная струя воды ткацкий станок

Текстильный бархатный ткацкий станок цена

100kgs-500kgs малой мощности открытый хлопка mop Скручивания Пряжи Машина

AGEN983-A/B оборудование для производства пряжи с воздушным покрытием, двигатель

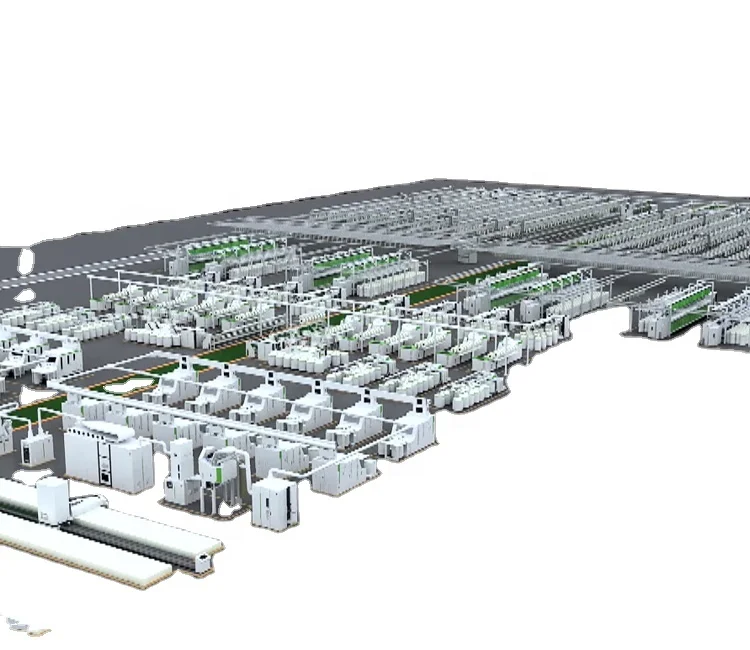

Qingdao Hongda JINGWEI бренд, Лидер продаж, текстильное оборудование, автоматическая машина для спиннинга, вся линия для хлопка

Новинка, изготовленный на заказ, хороший продавец, металловращающийся станок с ЧПУ, распродажа, готовый к отправке

Новые поступления

Новинки товаров от производителей по оптовым ценам