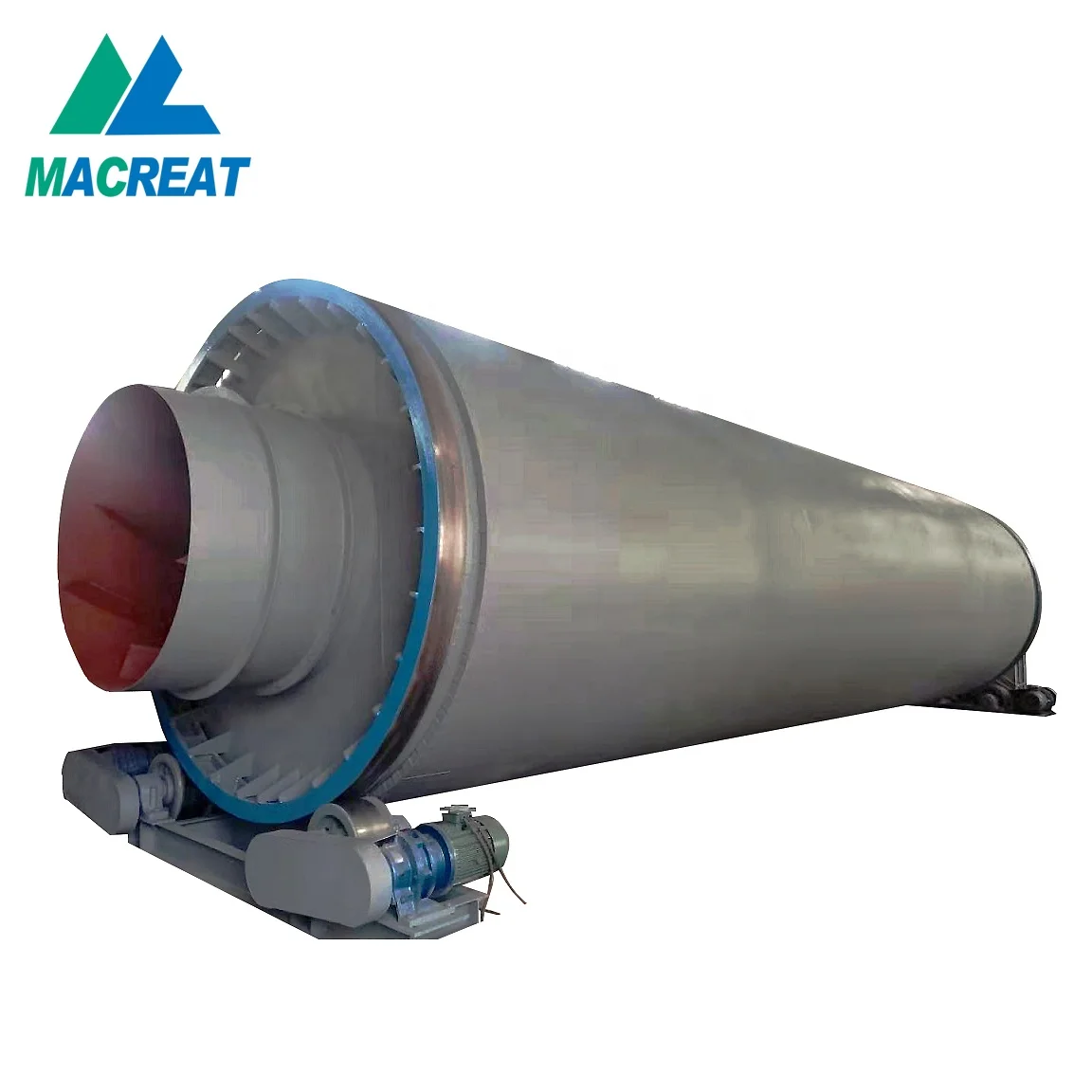

The working principle is that the steam generated by steam generator, the heat exchanger transfer the hot air to the inside of

the drying cabinet body through the circulation fan , so that the moisture of the product is evaporated under the heat action.

Evaporated under the action, the generated moisture air is exhausted to the outside of the dryer along the moisture removing pipe.

The machine can continuously feed and make the material run smoothly.

100 кг промышленная сушильная машина для горячего воздуха abs частиц отходов пластика лома сушилка вертикальный термополиуретановый зерновой Дегидратор в

1 600,00 $