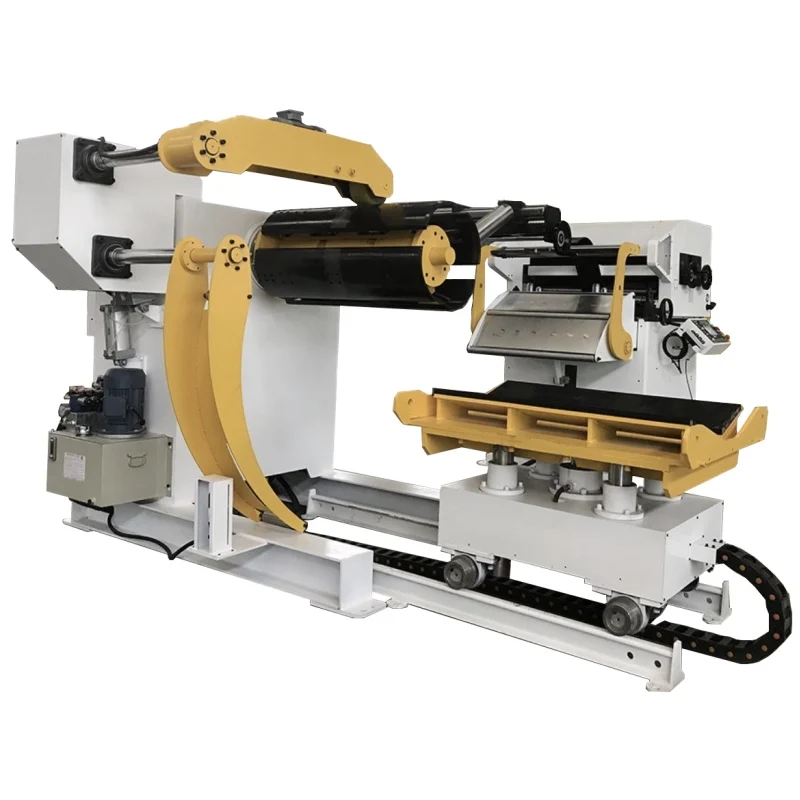

TNCF3 400 Coil Feeder 3 in 1 NC Servo Power Press Machine Feeding

- Категория: Other Machine Tool Equipment >>>

- Поставщик: Shanghai Yingxin World Machinery Co. Ltd.

Сохранить в закладки 1600129080807:

Описание и отзывы

Характеристики

Main Features of coil feeder 3 in 1:

-Coil thickness max 3.2mm

-Coil width max 400mm

-Coil weight 2000kg max

-Feeding speed: 16m/minute max

-Servo motor YAKSAWA

-PLC Mitsubishi

1. Straightening & Servo Feeding part:

Basic parameters/features | Descriptions | |

Feed width | 75-400mm | The inlet width is adjusted via high precision screw rod |

Feed length | Max 9999.99mm | Input the actual needed lengths via the HMI |

Applied thickness | 0.4-3.2mm | Straightening roll: upper 5 / lower 4, Ø54mm, Guide roll: 2 groups Ø75mm, roll fabricating material adopts high alloy bearing steel, through heat treatment (tempering + high frequency treating + hard chrome plating), the rigidity and surface smoothness is assured. |

Servo motor | 2.9KW | Adopt servo motor and drive from YASKAWA, PLC from MITSUBISHI, HMI touch screen from HITECH. |

Feeding accuracy | ±0.10mm | It’s though the servo motor driving the high precision planetary reducer, then drive the feeding roll via MXL, and eliminate mechanical error. At the same time, the rolls are mesh engaged via high precision gear. Gear Material adopt high alloy mold steel, grinded after high precision gear hobbing, with high precision and long service life. |

Release method | Pneumatic release (5KG/CM2) | Adopt double air cylinder. During adjustment, the air cylinder is will be ventilated, upper slide piston pushes down by cylinder pressure. When release, the cylinder release material by ascending slide piston. As quick exhaust valve is equipped the exhaust pipeline, high speed release is assured. |

Straightening adjustment | Through worm gear | Adopt 4 worm gear and worm rod for adjustment. Rotate the hand wheel to drive the worm gear, drive the upper slide lift, so as to realize the push-down amount adjustment. There are dial plates with the hand wheels, indicating the adjustment amount. |

Pass line adjustment | Electrically adjusted | There are 4 worm rod reducers equipped on the machine seat. The gear motor drive the worm rod to lift whole machine body. |

Release magnetic valve |

| High performance magnetic valve from KURODA |

Inlet method |

| Downward feed |

Feed direction | From left to right | Can be customized |

Pass line height |

| 1000mm±100mm (can be customized) |

2. Uncoiler part

Basic parameters/features | Descriptions | |

Coil loading width | 75-400mm | Coil loading width is adjusted by ‘A’ stoppers, convenient for loading and unloading coils |

Coil inner diameter | Ø508mm | Can be customized. |

Coil outer diameter | Ø1200mm | Can be customized. |

Machine frame load bearing | 2000KG | The main machine frame is welded from profile steel, A3 steel plates, #45 forged bearing seat, through annealing treatment. |

Uncoiler power | 1.5KW | 3 phase, 380V |

Uncoiler frequency converter | 2.2KW | Delta Frequency Converter |

Feed speed | 1-16M/min | Speed adjusted via inverter |

Brake method |

| Adopt pneumatic drum type brake, preventing the coil from getting loose due to rotation inertia. |

Loop control | Optical sensor | Adopt 2 groups of correlation optical sensors for loop control. When the strip loop falles into the effect scope of the first sensor group, the uncoiler reduces speed, while when the loop falls into the effect scope of the second sensor group, the uncoiler stop rotating. |

Pressing device |

| The press device lifts up and presses down by pneumatic cylinder, with an end wheel driven by a gear reducing motor. |

Supporter arm |

| The supporter arm is driven by hydraulic oil cylinder. |

Required air pressure | 0.5Mpa | Pneumatic cylinder and accessories adopt AIRTAC or SUNRISE. The user provides the air source. |

Required hydraulic pressure | 7Mpa | Hydraulic motor and related hydraulic parts adopt ASGUN |

Basic parameters/features | Descriptions | |

Coil car traverse speed | 4 M/min | Gear reducing motor, chain drive |

Coil car lift capacity | 2000KG | ’V’ saddle, lift up and down with 4 guide posts. |

Hydraulic accessory |

| It shares the hydraulic motor with the uncoiler, with extra relevant control units. |

Coil car lift stroke | 300MM | |

Похожие товары

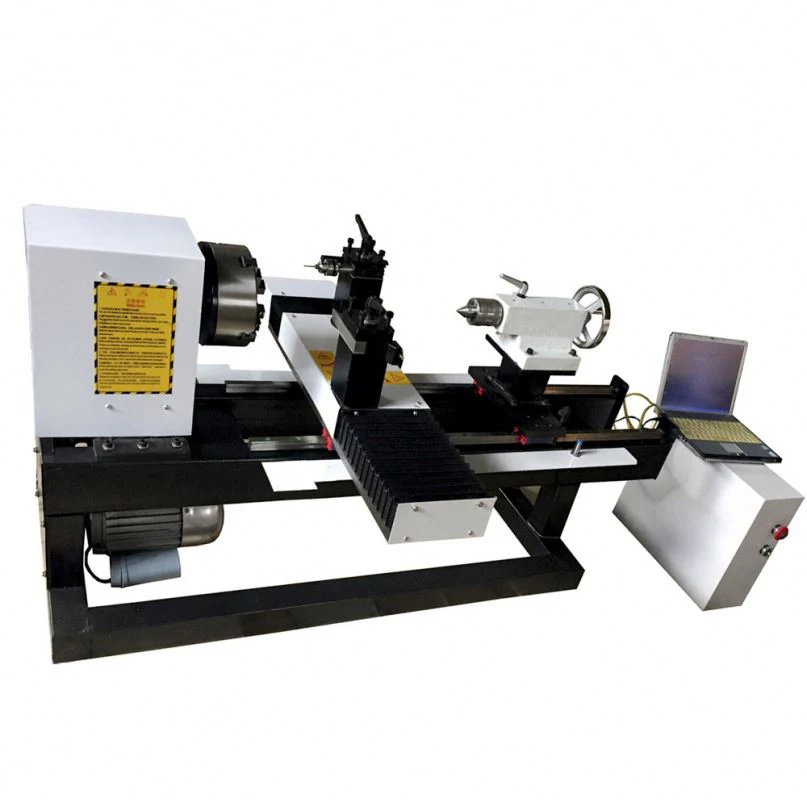

Токарный станок по дереву, цена, мини токарный станок по дереву

Ручной Мини-тормоз TTMC для металла, 8 дюймов

KCJC-1000H вертикальная машина для индукционной закалки станков с ЧПУ полным цифровым управлением системы

Другое оборудование для инструментов, индивидуальный визуальный измерительный прибор круглой формы

Роликовая машина Hutz с металлическими шариками, ручное управление с подставкой BRM18

Автоматическая гидравлическая погрузочная машина для размотки рулонной стали

LC-10T горизонтальный протяжной станок

Новые поступления

Новинки товаров от производителей по оптовым ценам