Мини настольный SMT хорошая цена о недорогом маленьком селективный DIP пайки волной припоя горшок машина TB680

- Категория: Оборудования для электронных изделий >>>

- Поставщик: Beijing Torch SMT Incorporated Company

Сохранить в закладки 1600142705185:

Описание и отзывы

Характеристики

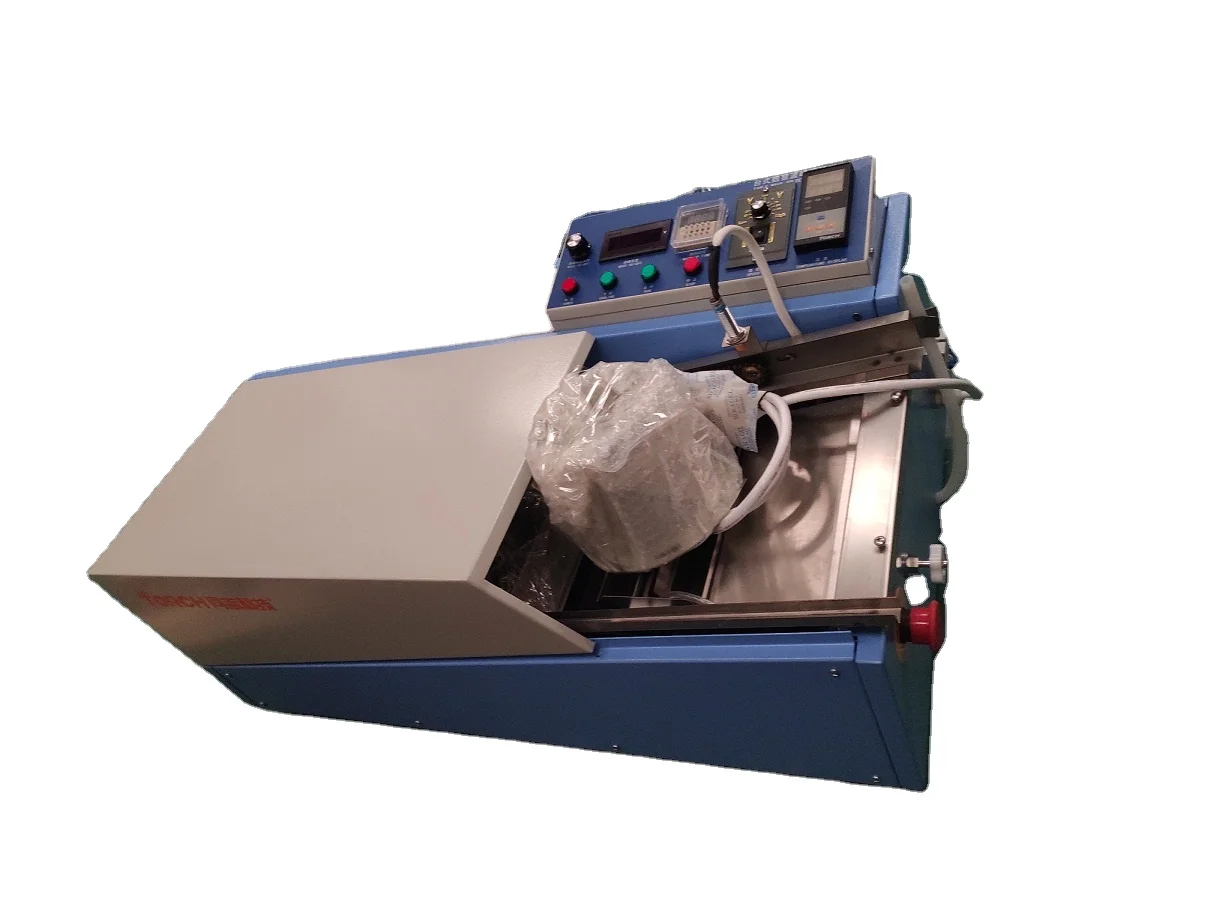

TORCH Mini Desktop SMT Good Price Cheap Small Selective DIP Wave Soldering Pot machine TB680

ⅠSummary

Desk wave soldering machine TB680 has been developed by Torch, It is the first equipment in small type wave soldering field. TB680 is suitable for research center, war industry, middle- and small-sized corporation, small private corporation and other electronic production companies. It is a desk-type, taking up small room, with multi-functions, energy-saving and high efficiency. The operation is easy and especially suitable for small and middle batch production.

Ⅱ Main technology parameters

max power: 3KW

pot capacity: 37Kg tin

max PCB size: 200X270mm (max)

temperature range: 200-300°C LED display

preheating temperature: 70-90°C

height range of wave crest: 5-12mm

Melting time: 80min

flux spray : froth

power supply: 220V±1%V AC single phase 50Hz

(please connect power to the ground)

transmission speed: 0.5-3m/min

dimension : 850X600X330mm

net weight: 48Kg

Function

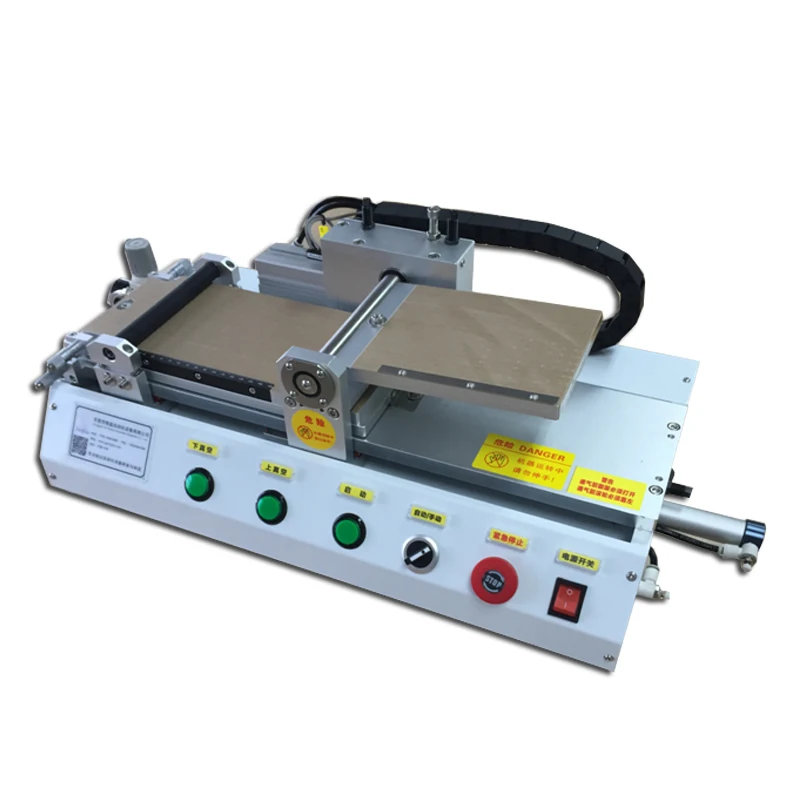

There are 6 parts: flux, preheating, soldering, electrical controlling, exhaust unit and convection unit.

- Flux

Flux parts are made of air pump, air tube, pin valve, filter, froth tube and flux box.

Flux

There is flux belt on the froth tube, PCB whose side has chips is on the top and touch flux, the side will has flux film.

preheating

It is made by melt board with resistor to provide heat for PCB.

soldering

It is made by tin pot, heating board, wave pump and tin.

1 tin pot 2 clapboard 3 nozzle 4 regulator 5 wave pump 6 channel |

Soldering

Figure 3: The solder will be divided into upper and lower levels by clapboard, the lower for the high-pressure layer, the upper layer for the low-pressure layer, liquid solder will be into high pressure layer driven by wave pump, the solder in the high pressure layer rotate and then pass regulator, it will overflow from the nozzle, the wave crest form and then fall into low pressure layer because of gravity

4 electrical controlling

With modular structure, transmission speed, solder temperature, preheating time and others can be adjusted and controlled. Working principle is shown in Figure 4.

Figure 4 electrical controlling

- exhaust unit

It is made of cover, air fan, air cover and air tube. All exhaust generated in soldering will be eliminated.

- convection unit

It is made of chain, rail, drive and pallet. PCB will be sent in flux unit, preheating unit and soldering unit by convection unit.

Company:

Похожие товары

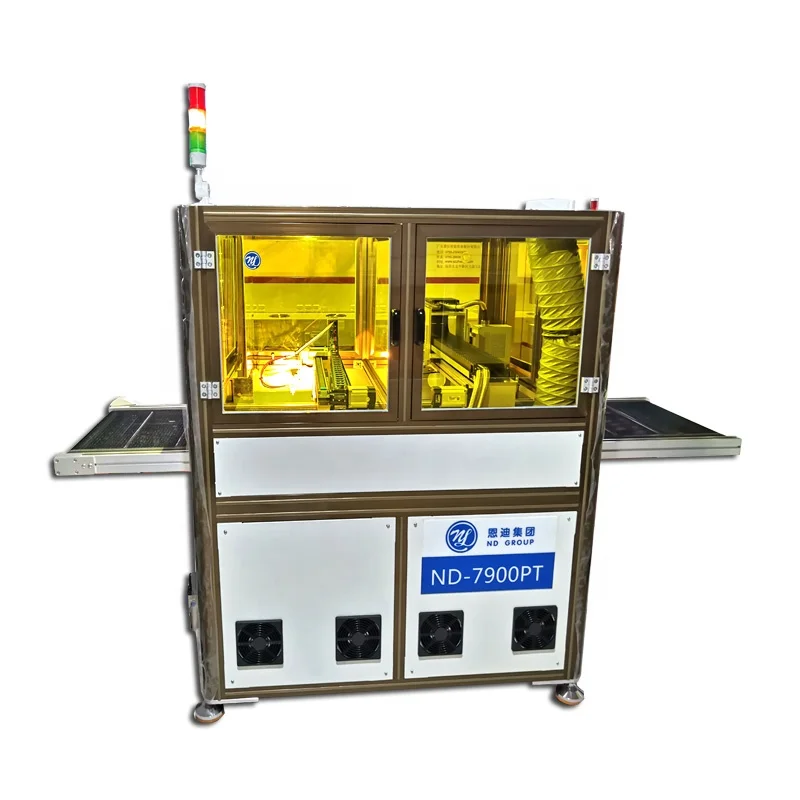

Машина для производства закаленного стекла для мобильного телефона машина для производства закаленного стекла машина для защиты мобильного экрана

Машина для резки закаленного стекла, машина для производства закаленного стекла 6d, машина для резки закаленного стекла

Оборудование для производства мобильных телефонов --- ND 1311KL

Передвижная закаленная стеклянная a4 прайс-лист из закаленного стекла для резки машина цена в Индии

Аппарат для производства закаленного стекла nd cnc, линия по производству закаленного стекла, аппарат для ламинирования

Мобильная стеклянная машина --- ND-1001TH

Машина для защиты экрана из закаленного стекла, машина для резки закаленного стекла для телефонов

Новые поступления

Новинки товаров от производителей по оптовым ценам