LSAG 4C ISO жидкое лекарство стекло стерилизации машина для наполнения и запайки ампул Автоматическая стерилизация разливочная

- Категория: >>>

- Поставщик: Herun Machinery (Shanghai) Co. Limited

Сохранить в закладки 1600218162117:

Описание и отзывы

Характеристики

Introduction:

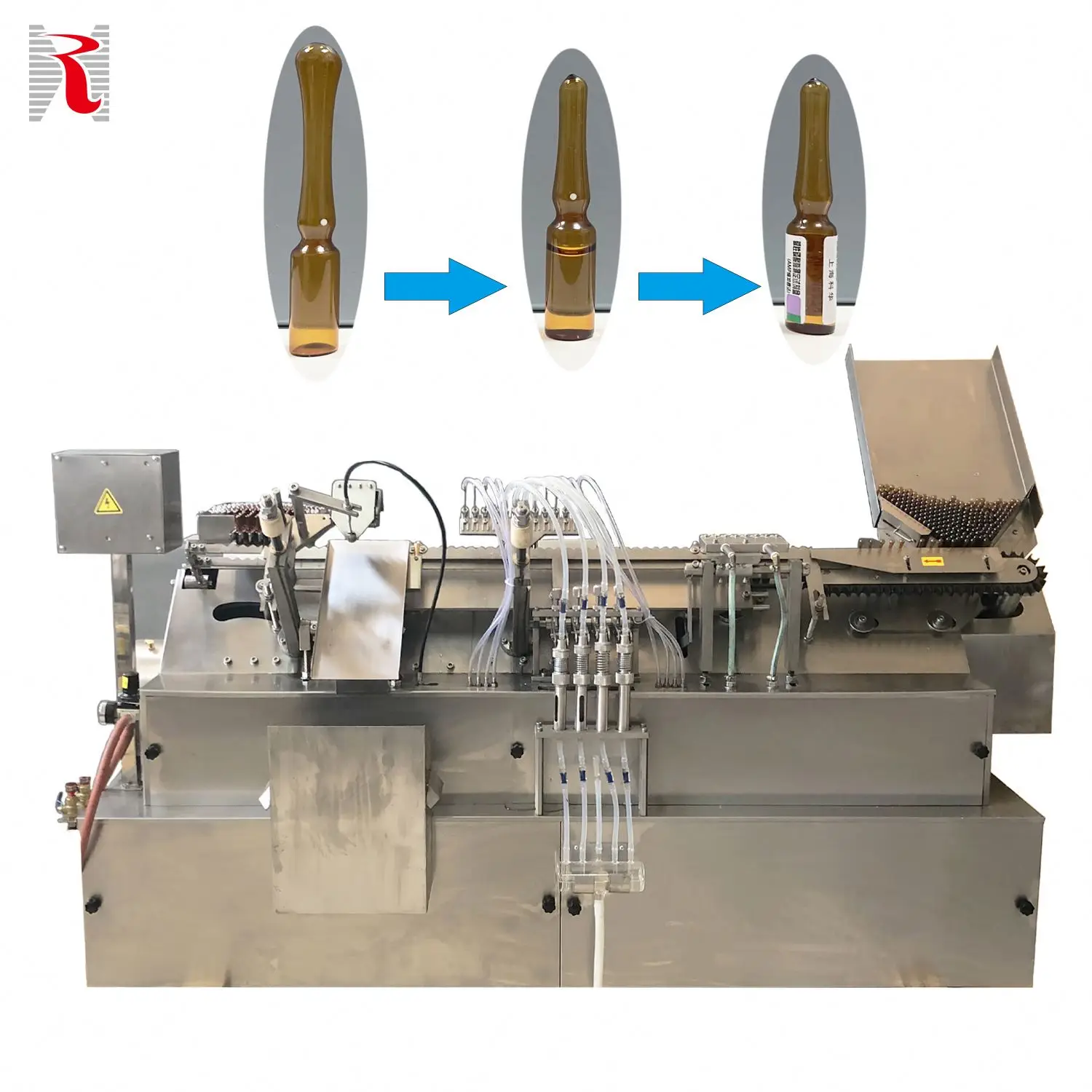

This machine is a new generation of single-machine multi-needle wire drawing filling and sealing machine.

The rectangular bottle conveying method is adopted in the design to make the conveying ampoule more stable and the bottle breaking rate is lower.

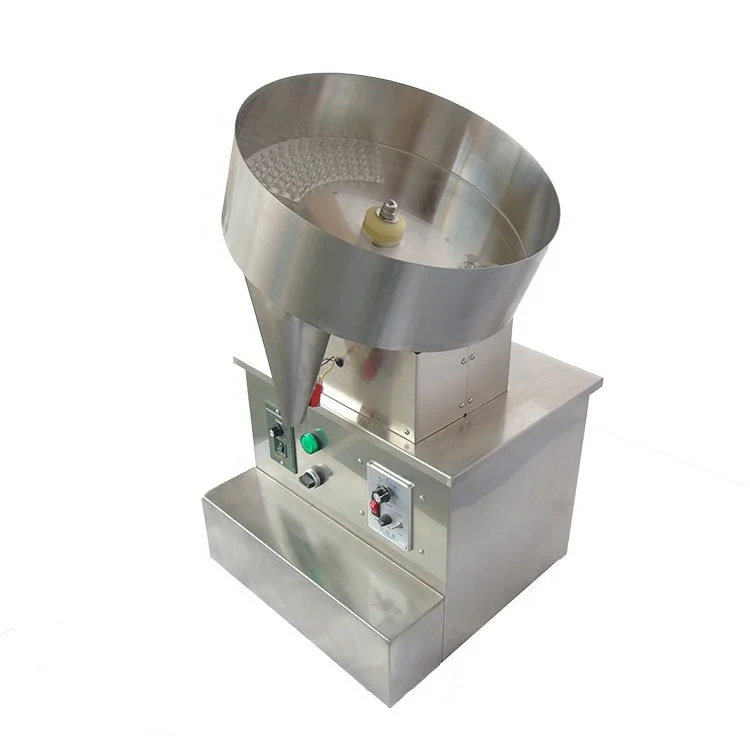

The hopper feeding bottle is equipped with a new type of clutch device, which can stop conveying the ampoule closed bottle without stopping the machine, so as to reduce the loss of the ampoule closed bottle.

The filling stopper system is mechanically controlled and has strong reliability. The bottle discharging mechanism abandons the traditional bottle conveying method, and the unscramble bottle is more reasonable and the finished product rate is higher.

It is suitable for the filling and sealing wire drawing of closed ampoule bottles in pharmaceutical factories.

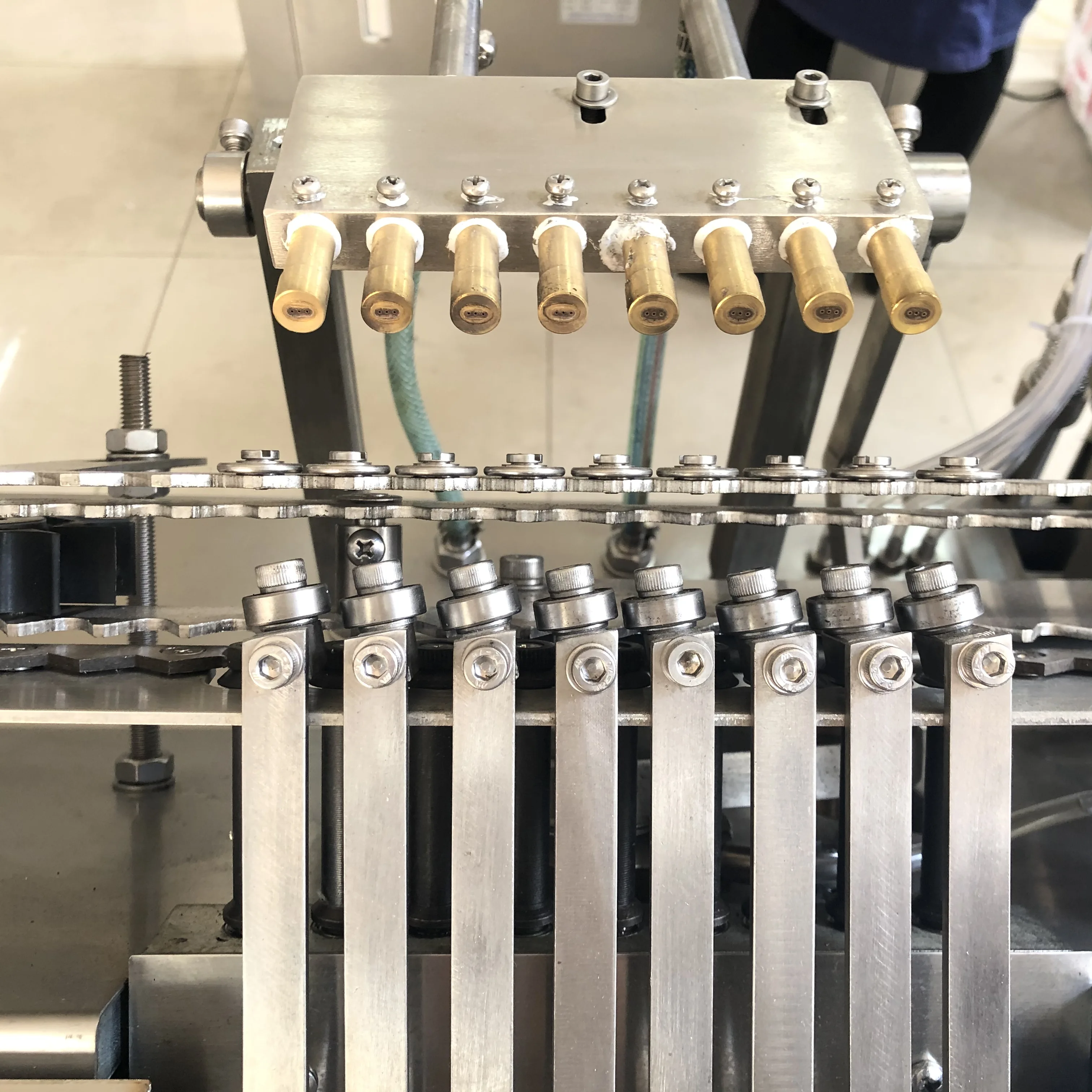

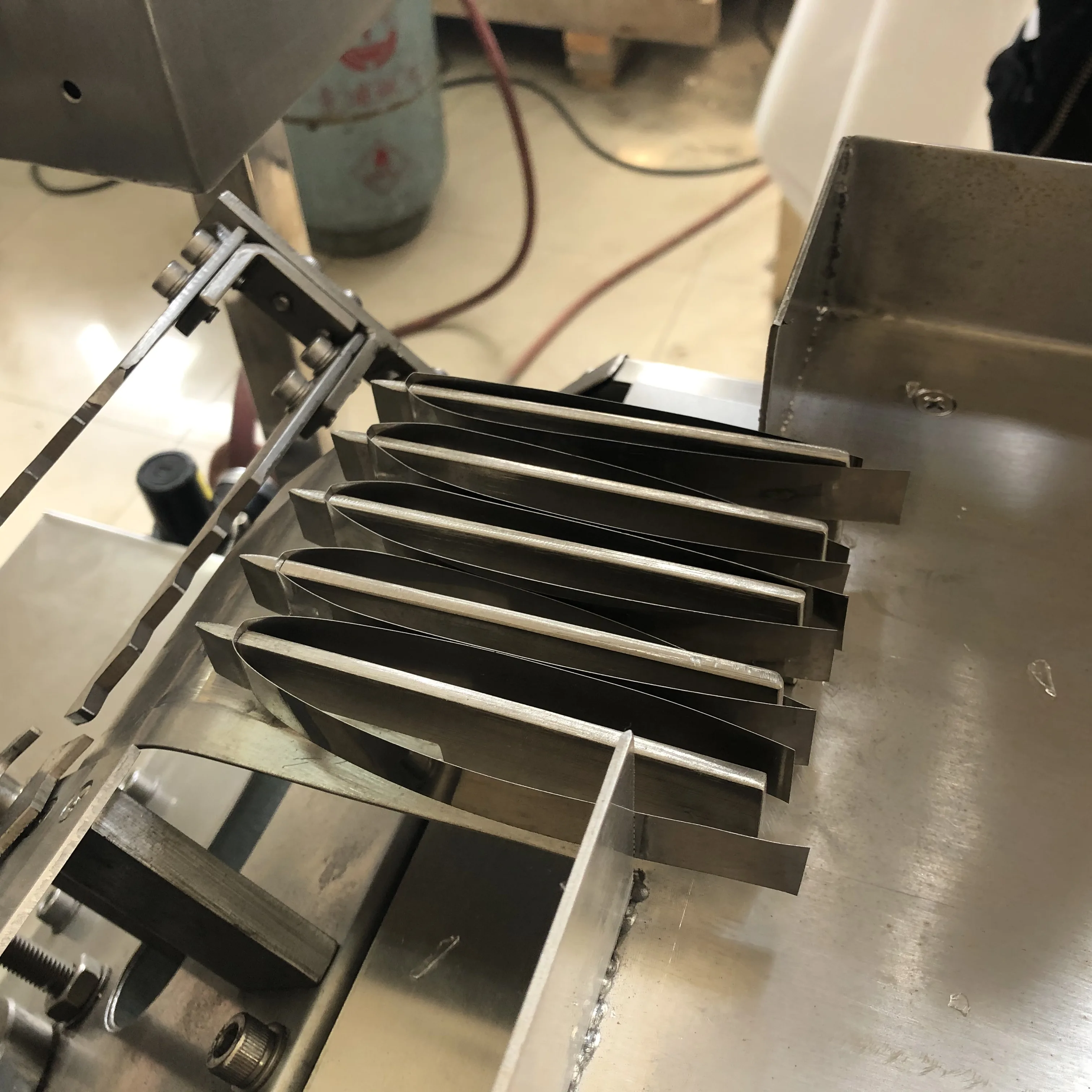

This machine is a four-position stepping drive system. Each time a group of four bottles is sent to each process point to complete the bottle preheating opening and pre-filling with nitrogen. Medicine filling, nitrogen filling, preheating, wire drawing and sealing, etc., liquefied petroleum gas or city gas acetylene.

This machine is a new generation of single-machine multi-needle wire drawing filling and sealing machine.

The rectangular bottle conveying method is adopted in the design to make the conveying ampoule more stable and the bottle breaking rate is lower.

The hopper feeding bottle is equipped with a new type of clutch device, which can stop conveying the ampoule closed bottle without stopping the machine, so as to reduce the loss of the ampoule closed bottle.

The filling stopper system is mechanically controlled and has strong reliability. The bottle discharging mechanism abandons the traditional bottle conveying method, and the unscramble bottle is more reasonable and the finished product rate is higher.

It is suitable for the filling and sealing wire drawing of closed ampoule bottles in pharmaceutical factories.

This machine is a four-position stepping drive system. Each time a group of four bottles is sent to each process point to complete the bottle preheating opening and pre-filling with nitrogen. Medicine filling, nitrogen filling, preheating, wire drawing and sealing, etc., liquefied petroleum gas or city gas acetylene.

Technical Parameters

Equipment name | Ampoule closed bottle filling and drawing machine | Model specification | LSAG-4C(1ML) |

Production capacity | 4000-5000 pcs/hour | Motor Power | 0.84KW 380V |

weight | 400Kg | Dimensions | 1800*900*1350mm |

Fuel and consumption | Liquefied petroleum gas\\pipeline gas 0.9-1 cubic meter/hour | ||

Fuel and amount | Oxygen 0.08-0.1 cubic/hour | ||

Похожие товары

Автоматическая машина для розлива оливкового кокосового эфирного масла двигатель насоса горячий продукт 2022 Розничная розничного

ZONESUN ZS-BSP4525 машина для упаковки термоусадочной пленки в тоннель бутылок с автоматической

Аппарат для подсчета таблеток в капсулах

Машина для наполнения сыром чесноком специями порошком 250 г 1 кг

LTEC-24 высокой скорости с двойной головкой автоматический электронный счетная машинка для денег капсулы

Полуавтоматическая инкапсуляционная машина фармацевтического класса малой емкости, маленькая, Размер 000-Размер 5

G2WY 2 головки жидкое мыло моющее средство 5-галлонная бутылка/20L

Новые поступления

Новинки товаров от производителей по оптовым ценам